Effective operation of high-pressure cleaning tools depends on a thorough understanding of their key components. Every device is made up of multiple elements that work together to ensure optimal performance. Recognizing how these parts interact can help in both maintenance and troubleshooting when issues arise. This knowledge not only enhances the longevity of the equipment but also improves its overall efficiency during cleaning tasks.

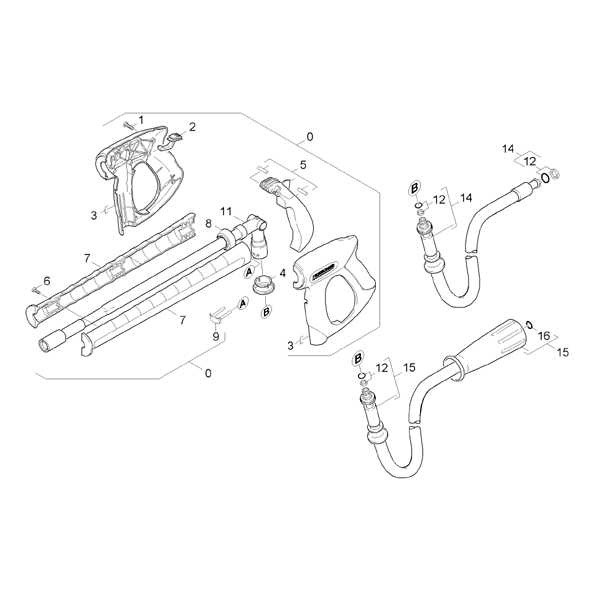

Every component plays a specific role in the smooth functioning of the device. From the trigger mechanism to the flow control, each piece is integral to delivering power and precision. A clear understanding of how these pieces fit together can simplify repairs and replacements, ensuring the cleaning system operates at its best for longer periods.

Proper maintenance and timely replacement of worn parts are critical for maintaining peak functionality. Whether you are a professional or a homeowner, knowing which components require attention and when can save both time and money. This guide offers a closer look at these essential components and how to ensure they remain in optimal condition.

Understanding High-Pressure Cleaning Equipment Components

To achieve the best results with a high-performance cleaning device, it is essential to comprehend the various elements that make up the system. Each part has a specific function that contributes to the overall effectiveness and efficiency of the tool. Understanding how these components interact ensures that the equipment operates smoothly and that any issues are quickly identified and addressed.

Key Elements of the Cleaning Tool

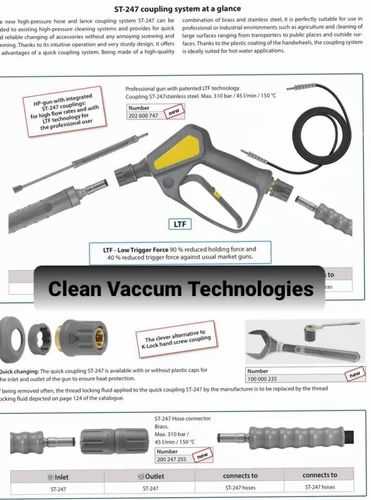

The essential components of a cleaning system include the control mechanisms, nozzles, hoses, and connectors, among others. Each of these elements works together to ensure the proper flow of water, the control of pressure, and the delivery of force to clean surfaces effectively. Maintaining these components is crucial for preventing wear and tear, which could compromise the system’s performance.

Function and Maintenance of Essential Components

Regular inspection and maintenance of these key parts will help avoid costly repairs or replacements. For example, the trigger mechanism regulates water flow, while the nozzle affects the cleaning coverage and pressure. Proper care ensures that these components remain in good working condition, providing consistent and reliable performance over time. Neglecting minor issues can lead to bigger, more expensive problems down the line.

Common Components and Their Functions

Every cleaning device operates through a series of interconnected elements that work together to deliver high-performance results. Each component plays a specific role, ensuring the tool functions as expected. Understanding these key parts and their functions can help users maintain the equipment effectively and troubleshoot any issues that may arise during operation.

Trigger Mechanism

The trigger mechanism is responsible for controlling water flow. When activated, it allows water to pass through the system, directing it toward the nozzle. This component ensures precise control over the flow and pressure, allowing users to adjust the cleaning force as needed. A malfunctioning trigger can lead to inconsistent water flow, compromising the cleaning process.

Flow Regulator

The flow regulator is another essential element, as it controls the amount of water that is dispensed during operation. By managing the flow rate, this component ensures that the system delivers the right pressure for various cleaning tasks. If the flow regulator becomes clogged or damaged, it can significantly reduce the efficiency of the device, making regular maintenance crucial. Timely inspection helps prevent potential performance issues.

How to Maintain Cleaning Tool Components

Proper maintenance of your cleaning equipment is essential for ensuring long-lasting performance and preventing breakdowns. Regular care of the key components not only enhances the tool’s efficiency but also reduces the need for costly repairs. Taking a few preventive steps can go a long way in keeping the system in optimal condition for frequent use.

Regular Inspection and Cleaning

One of the most important steps in maintenance is regular inspection. Check the components for signs of wear, damage, or blockages. Clean the nozzles and connectors to prevent debris buildup that could reduce flow or cause clogs. Be sure to inspect hoses for leaks or cracks, as damaged hoses can significantly impact the tool’s performance.

Lubrication and Storage

Lubrication is vital for moving parts, particularly the trigger mechanism. Apply a light lubricant to ensure smooth operation and avoid friction that could lead to premature wear. Additionally, store the equipment in a dry, cool area when not in use to prevent exposure to extreme temperatures or moisture, which could cause corrosion. Proper storage and care between uses can extend the lifespan of the equipment.