Understanding the structure and individual elements of farming equipment is essential for proper maintenance and repair. This guide will provide a detailed overview of the essential components, their functions, and how to identify and replace them when necessary. Whether you are a technician or a farmer, knowing the exact layout of the machine helps in ensuring its efficiency and longevity.

We will explore how to interpret technical illustrations that display the full range of mechanical parts, making it easier to pinpoint specific areas in need of attention. This approach will not only assist in identifying damaged components but also in acquiring the correct replacements without confusion.

Efficient operation depends on understanding the intricate details of machinery. In this guide, we will help you navigate through the complex system of mechanical pieces, ensuring that you are prepared to handle any troubleshooting or repair task with confidence.

Understanding the New Idea 5209 Parts

To fully grasp the functionality of a farming machine, it’s important to understand how its individual components work together. Each element plays a vital role in ensuring smooth operation and maximum efficiency. Familiarizing yourself with the different sections of the equipment allows for quicker troubleshooting and more effective repairs when needed.

Key Components and Their Functions

Every farming machine is made up of various sections that each serve a specific purpose. These parts work in unison to ensure that the overall system runs smoothly. From the drive mechanisms to the control units, each component contributes to the machine’s performance. Understanding how each element functions will help in diagnosing issues and performing repairs more efficiently.

Maintenance Tips for Optimal Performance

Regular maintenance is crucial for keeping machinery in peak condition. This involves inspecting each component for signs of wear and tear, ensuring everything is well-lubricated, and replacing damaged parts promptly. Proactive care can prevent major malfunctions and extend the lifespan of the machine.

How to Read the Parts Diagram

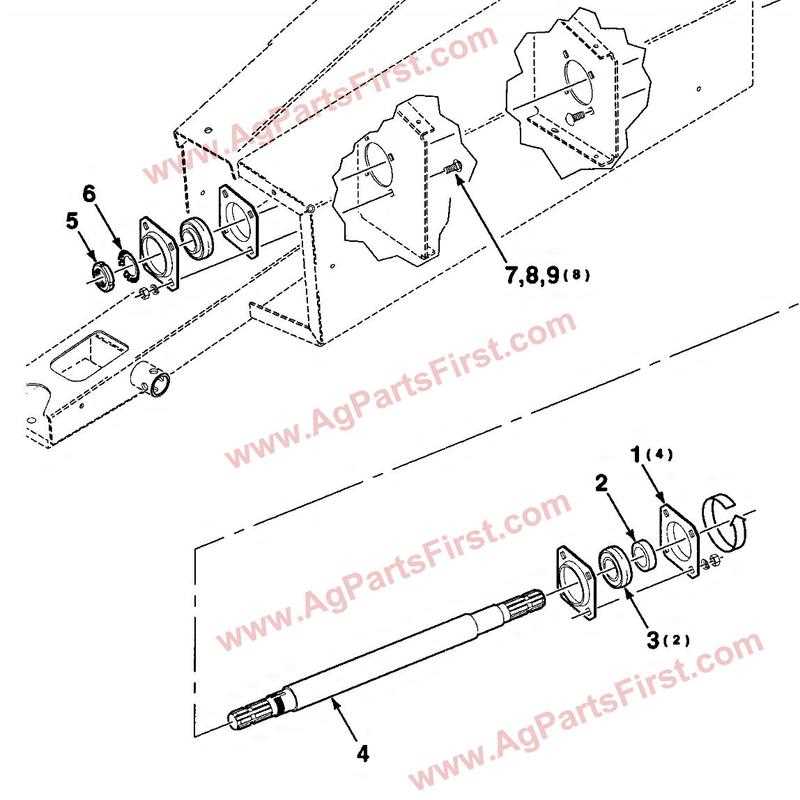

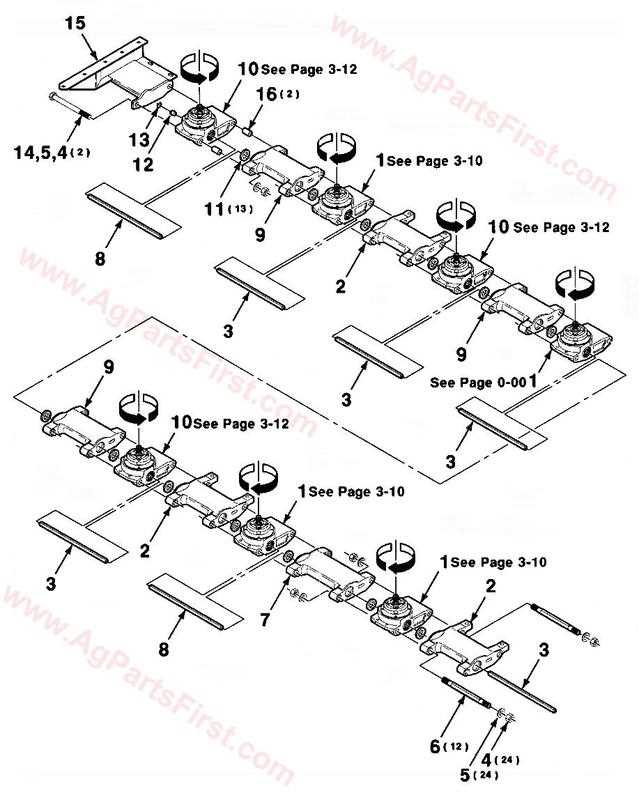

Interpreting technical illustrations of machinery can initially seem overwhelming, but understanding the key features can make the process much easier. These visual representations are designed to simplify complex systems, allowing users to identify each individual component and its role within the machine. By following specific markers and labels, you can gain a clear understanding of the layout and function of the various elements.

Identifying Components and Their Connections

The first step in reading such illustrations is recognizing the labels and symbols used for each part. Each component is typically marked with a unique reference number or letter, which corresponds to a detailed list or a catalog. These labels help you easily match parts to their location in the system. Understanding how these elements are connected visually allows for quicker identification and maintenance.

Using the Diagram for Repairs and Upgrades

Once you are familiar with the key components and their placement, this knowledge becomes invaluable when performing repairs or upgrades. The visual guide helps you locate problematic areas, order the correct replacements, and reassemble the system with confidence. Properly interpreting these illustrations ensures that every step of the process is completed efficiently, preventing mistakes and saving time.

Common Issues and Component Replacement

Over time, machines experience wear and tear due to regular use, which can lead to a range of common issues. Recognizing these problems early can prevent more serious damage and costly repairs. By understanding the most frequent failures and knowing how to replace the faulty elements, you can keep the system running smoothly and extend its lifespan.

Frequent Problems and Their Causes

Common issues often involve components such as belts, motors, or gears, which may wear out from extended use or improper maintenance. A worn-out drive belt, for instance, can cause poor performance and even lead to system failure. Regular inspection and prompt replacement of such items can prevent unexpected downtime. Additionally, malfunctioning control mechanisms or faulty hydraulic systems are frequent culprits, often caused by wear or a lack of lubrication.

Steps for Replacing Damaged Components

Replacing damaged components requires careful attention to detail. Begin by consulting the manual to identify the exact specifications for each part. Then, follow the diagram to locate the damaged item, ensuring you have the correct replacement ready. Proper installation is key to avoiding further damage, so take time to securely fit the new parts and verify the system’s functionality before resuming full operation.