Proper maintenance and repair of any equipment require a clear understanding of its internal structure. Knowing the layout and function of each component can significantly enhance the longevity and performance of your device. Whether you’re looking to fix a specific issue or perform routine upkeep, a thorough knowledge of the tool’s build is essential.

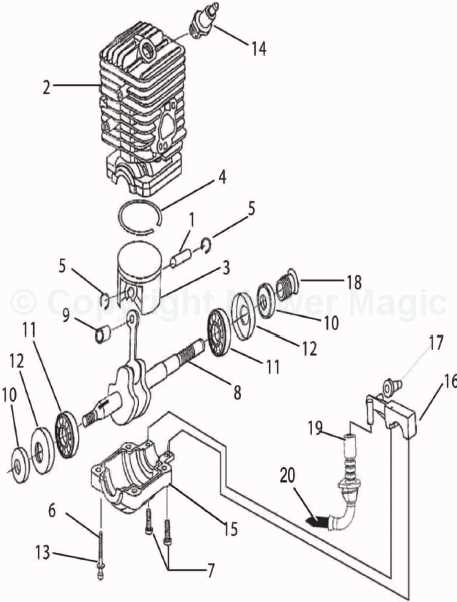

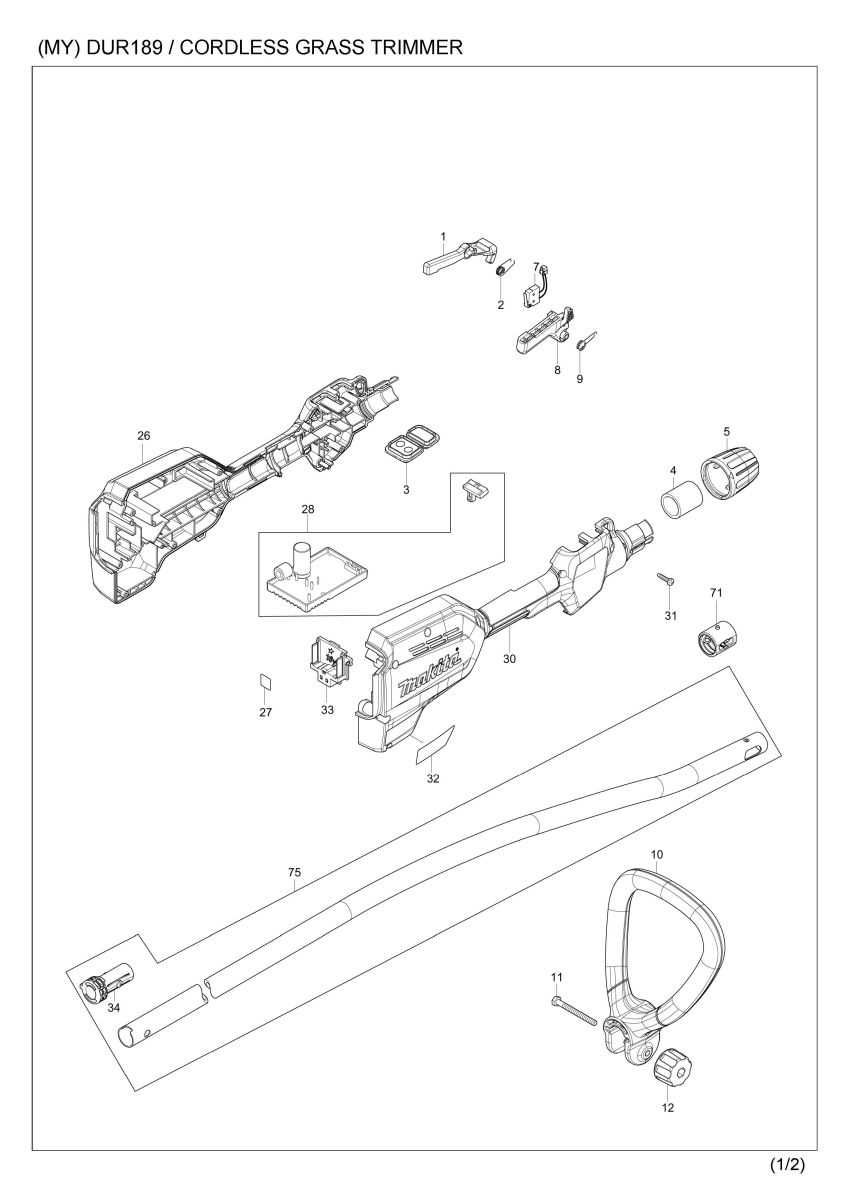

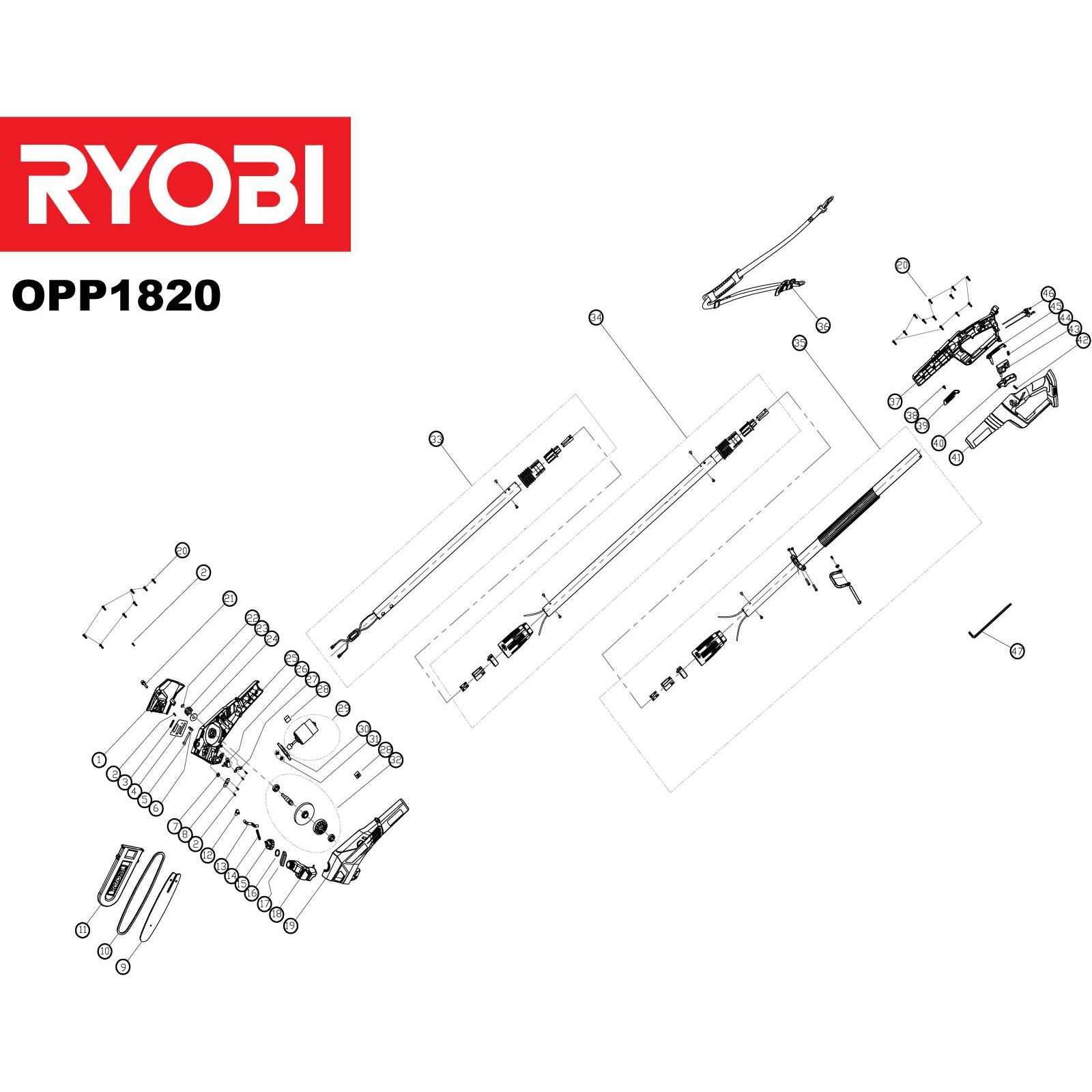

Identifying individual elements within the machine can be a daunting task without a reference. However, with a detailed breakdown, users can easily locate the source of problems and address them efficiently. This understanding also helps in the proper assembly and disassembly of the unit when necessary.

Once you’re familiar with each section, you can ensure that all pieces are in good condition, leading to smoother operation. Regular attention to even the smallest parts will prevent major breakdowns and help maintain your equipment’s optimal function over time.

Understanding Tool Components

Every mechanical tool consists of various interconnected elements that work together to ensure smooth operation. Recognizing the function and location of each piece is crucial for anyone who needs to repair, maintain, or enhance the performance of the equipment. A clear grasp of these components can simplify troubleshooting and extend the lifespan of the tool.

Key Components and Their Functions

Each section of the device serves a specific role. Some parts are responsible for power transmission, while others ensure stability, mobility, or cutting precision. Understanding how each component interacts within the system allows for effective maintenance, ensuring that all elements function cohesively.

Assembly and Maintenance Tips

Regular inspection and proper assembly are vital for keeping your tool in working condition. By following a clear guide on the structure and setup of each section, you can avoid common mistakes that could lead to unnecessary damage or malfunction. Periodic cleaning and checking for wear will also help in identifying issues before they require major repairs.

How to Identify Each Component

Recognizing the individual elements of a device is the first step in understanding its functionality. Whether you’re repairing a malfunction or assembling the equipment, knowing where each piece fits and its specific role is essential. This knowledge helps avoid errors and ensures that every element is correctly positioned and functioning properly.

Using Visual Cues

When attempting to identify a component, look for distinct features that can help differentiate each part. These may include shapes, sizes, or markings that indicate a specific function or position. By focusing on these visual cues, you can quickly pinpoint where each piece belongs and how it interacts with the rest of the system.

Consulting Reference Materials

If visual identification isn’t enough, turning to a detailed reference guide can provide additional insights. Manuals and technical resources often include labeled illustrations that offer clear depictions of each part and its placement. Using such references allows for more accurate identification and ensures that all pieces are correctly assembled or replaced.

Step-by-Step Guide to Repairs

Repairing mechanical equipment requires careful attention to each step of the process. A methodical approach not only ensures the correct diagnosis of the issue but also helps in executing repairs effectively. Following a structured guide simplifies the task and reduces the risk of further damage during the process.

Tools and Preparations

Before starting any repair, make sure you have the necessary tools and parts. This preparation minimizes downtime and ensures you can address the problem without interruption. Gather screwdrivers, wrenches, and any replacement components required for the repair.

Repair Process

| Step | Action | Details |

|---|---|---|

| 1 | Turn off the power | Ensure the device is unplugged or turned off before beginning work. |

| 2 | Disassemble the tool | Carefully remove any covers or parts that may be in the way of the malfunctioning component. |

| 3 | Inspect the damaged part | Examine the part thoroughly for signs of wear or damage. Make sure to check for loose connections. |

| 4 | Replace or fix the part | Install the replacement or repair the damaged component following the manufacturer’s guidelines. |

| 5 | Reassemble the tool | Carefully put the tool back together, ensuring all components are securely attached. |

| 6 | Test the equipment | Power on the device to confirm that the repair was successful and everything is functioning properly. |

By following these steps, you’ll be able to confidently address common issues and restore your equipment to optimal working condition.

Fixing Common Problems with Equipment

Mechanical tools can sometimes encounter issues that prevent them from functioning efficiently. Identifying these problems early and addressing them promptly can prevent further damage and extend the lifespan of the device. From power failure to poor performance, most problems can be resolved with a few simple checks and fixes.

Identifying Power Issues

If the tool fails to start, the first step is to check the power source. Ensure that the battery or electrical connection is functioning properly. In some cases, dirty or corroded connections can interrupt the power flow. Cleaning or replacing the power components may resolve the issue.

Improving Cutting Efficiency

If the cutting performance is subpar, it could be due to dull components or misalignment. Inspect the cutting mechanism for wear and tear, and replace or sharpen any parts that are no longer effective. Additionally, ensure that all parts are correctly aligned to avoid unnecessary friction during operation.

Maintaining Your Tool

Proper maintenance is key to ensuring the longevity and performance of your equipment. Regular care prevents breakdowns and ensures that every part functions as it should. A few simple steps can go a long way in keeping your tool in top shape, saving both time and money on repairs.

Routine Maintenance Tasks

- Clean the tool after each use to remove dirt and debris.

- Inspect the components for wear and tear, replacing any damaged parts.

- Lubricate moving parts to reduce friction and maintain smooth operation.

- Check for any loose screws or bolts, tightening them as needed.

Storage and Care Tips

When not in use, store the tool in a dry, cool place to avoid moisture damage. Keep it away from extreme temperatures and ensure that the components are protected from dust and debris. Proper storage extends the life of your equipment and keeps it ready for the next task.

Preventative Care and Longevity Tips

Taking proactive steps to care for your tool can significantly increase its lifespan and ensure it operates efficiently for years. Regular attention to key areas helps avoid costly repairs and maintains optimal performance. Preventative care goes beyond simple cleaning – it involves habits that protect the tool from excessive wear and tear.

Essential Maintenance Habits

- Always check for debris or dirt after each use and clean the tool thoroughly.

- Ensure all moving components are well-lubricated to avoid friction and damage.

- Store the tool properly in a cool, dry environment to prevent rust or corrosion.

- Regularly inspect the tool for any signs of damage or misalignment, addressing issues early.

Extending Tool Life

In addition to routine care, using the tool appropriately and not overloading it will help prevent unnecessary stress on its parts. Following the manufacturer’s instructions for usage and avoiding harsh environments will also contribute to the tool’s long-lasting performance. Consistent preventative care ensures your equipment remains a reliable and durable asset for many tasks.