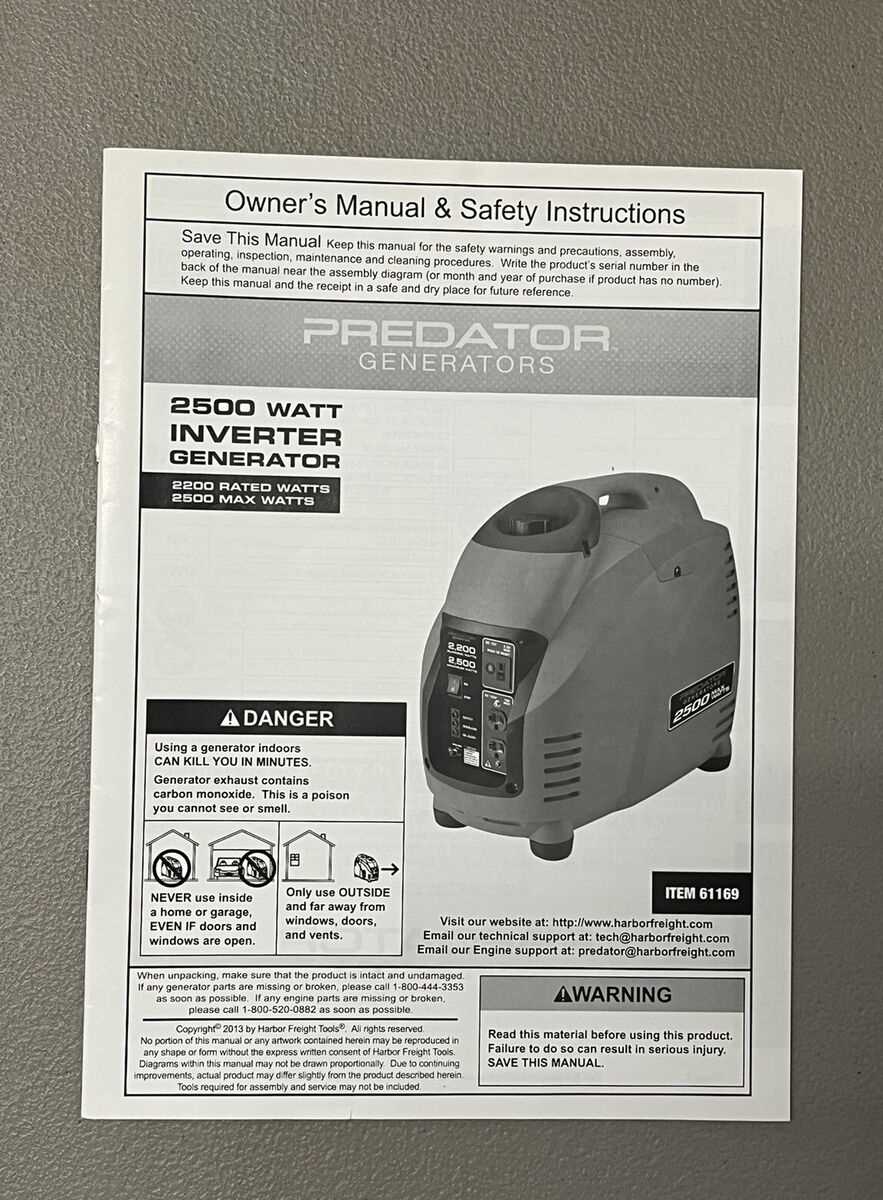

When maintaining and repairing portable power units, understanding the internal mechanisms and their function is crucial. Knowing how each component fits together and how it operates allows for more efficient troubleshooting and upkeep. Whether you are an experienced technician or a casual user, having a clear visual guide can make all the difference when dealing with malfunctioning equipment.

This guide will help you navigate through the key elements that make up the machine, providing a clear view of their layout and connections. With a comprehensive understanding, you can identify worn-out or faulty components with ease and take the necessary steps to restore the unit’s performance.

Effective maintenance begins with the right knowledge and tools, ensuring the longevity of your equipment. With proper care, your device can continue providing reliable service, saving you time and money in the long run.

Understanding Essential Components

When examining a portable power system, it is important to understand how various elements work together to generate and deliver electricity. Each component plays a vital role in the overall function, from the engine that provides the mechanical energy to the various electrical systems that regulate power output and safety features. A deeper understanding of these key parts allows users to troubleshoot effectively and ensure long-lasting performance.

Critical parts, such as the fuel system, ignition components, and the alternator, are essential for converting mechanical energy into usable electricity. Knowing how these elements interact helps identify potential issues, whether it’s an issue with fuel delivery or a problem with the voltage regulator. Maintenance and timely repairs can prevent common failures and ensure your unit operates smoothly when needed most.

Having a clear picture of the internal layout also aids in safer handling and operation. For example, the cooling system helps prevent overheating, while the exhaust components manage heat and emissions. Understanding how these systems function together is key to maintaining peak efficiency and extending the lifespan of your equipment.

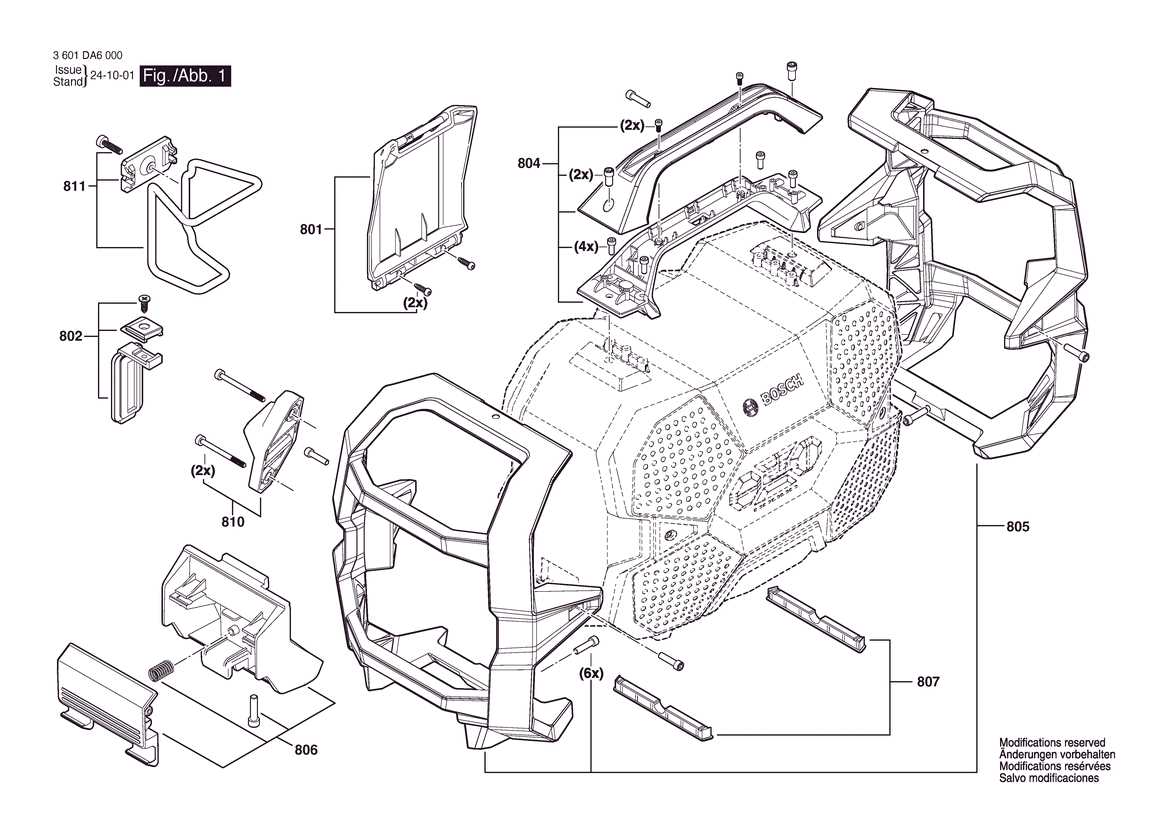

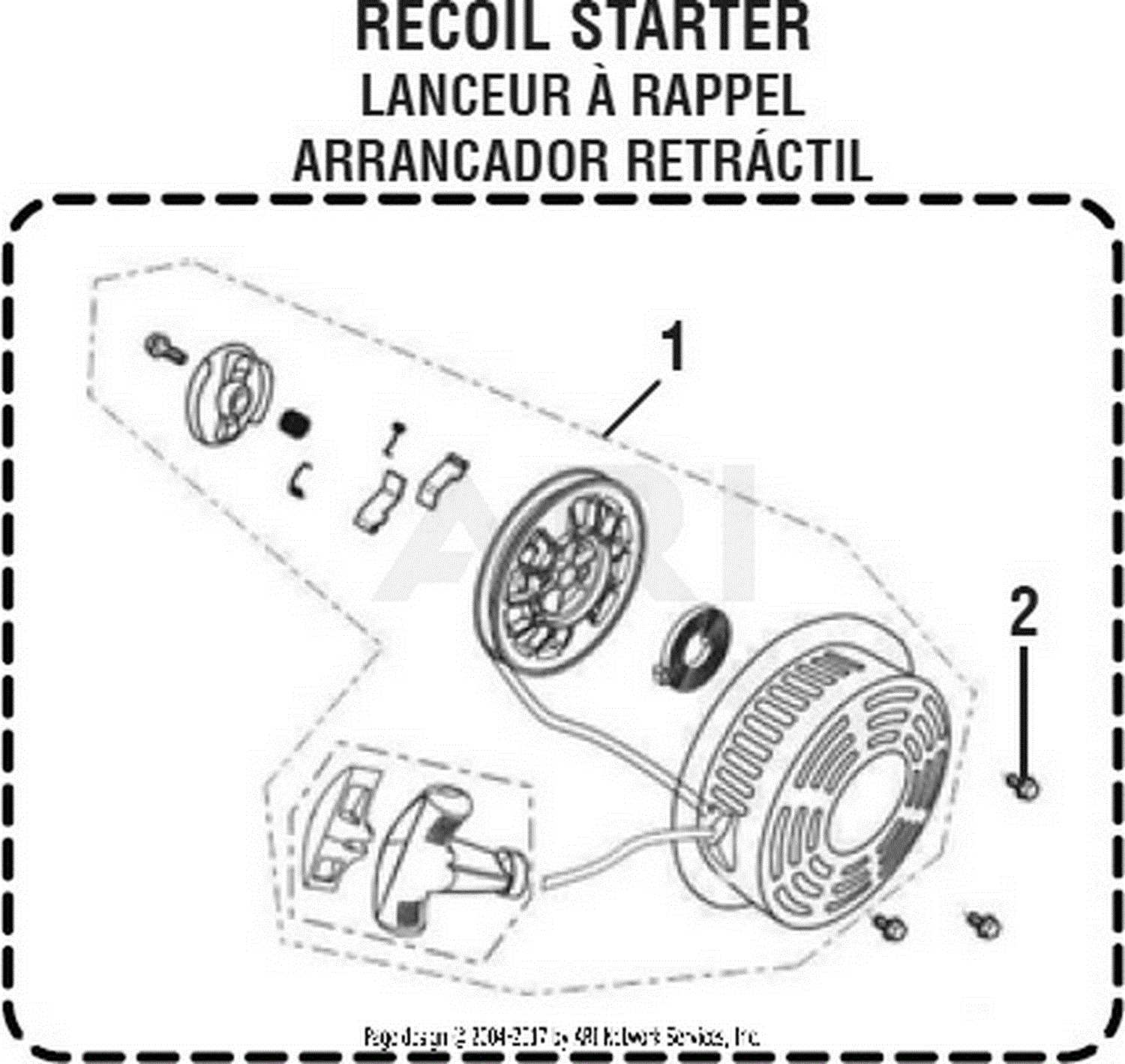

How to Use the Parts Diagram Effectively

Using a visual representation of your equipment’s internal layout is essential for both routine maintenance and repairs. This tool helps you quickly identify the location and function of each component, making it easier to spot issues and understand how to fix them. By following a clear guide, you can avoid unnecessary disassembly and ensure you focus on the problem areas.

Identify Key Components

The first step is to familiarize yourself with the most important sections of the system. Understanding the flow of electricity and the mechanical processes involved allows you to pinpoint where issues might arise. Pay attention to areas that are prone to wear and tear, such as the fuel or cooling systems, which are critical for efficient operation.

Follow the Layout for Troubleshooting

Once you have identified the key components, use the visual guide to trace the connections between them. This can be especially helpful when diagnosing electrical or mechanical failures. Each part is connected for a reason, and knowing how they work together will give you a better idea of where to focus your repair efforts.

Efficiency and precision in maintenance are achieved by using this tool properly, ultimately saving time and effort while ensuring that your unit stays in top working condition.

Common Issues with Essential Components

Even the most reliable equipment can experience problems over time, particularly with components that are subject to constant use and wear. Regular maintenance can prevent many of these issues, but some parts may still encounter common failures that require attention. Understanding these frequent problems helps users recognize and address them quickly to maintain the machine’s performance.

One common issue is with the fuel system, where clogs or contamination can prevent the engine from running smoothly. This can lead to inefficient fuel consumption or even complete failure to start. Another frequent problem involves the electrical components, such as the voltage regulator, which can malfunction due to excess load or a faulty connection, resulting in unstable power output.

Additionally, issues with the cooling system, such as blockages in the airflow or malfunctioning fans, can cause overheating, leading to potential damage to the engine or other internal parts. Regularly inspecting these areas can help prevent serious malfunctions and extend the lifespan of the unit.