Knowing the essential components of your cooling device is crucial for proper maintenance and repair. Recognizing each element and how they interact can significantly reduce the time spent diagnosing issues. A comprehensive understanding allows you to address problems with confidence, ensuring smooth operation and extending the lifespan of your unit.

By examining the internal elements of your appliance, you can gain valuable insights into its functioning. Whether it’s about replacing a faulty component or simply ensuring everything is in place, this knowledge empowers you to make informed decisions. Identifying parts and their roles within the system is a vital step in troubleshooting common malfunctions.

Properly interpreting this information helps identify specific issues early, preventing more serious damage. With the right approach, maintaining your device becomes a straightforward task, avoiding costly repairs and prolonging efficiency. Using the right tools and understanding the layout of key parts allows for accurate assessments of performance and possible failures.

Understanding Cooling Unit Components

Every cooling device consists of various components, each playing a critical role in its overall function. These elements work together to maintain the desired temperature and ensure the efficient operation of the appliance. Understanding how each part contributes to the system is key to effective troubleshooting and maintenance.

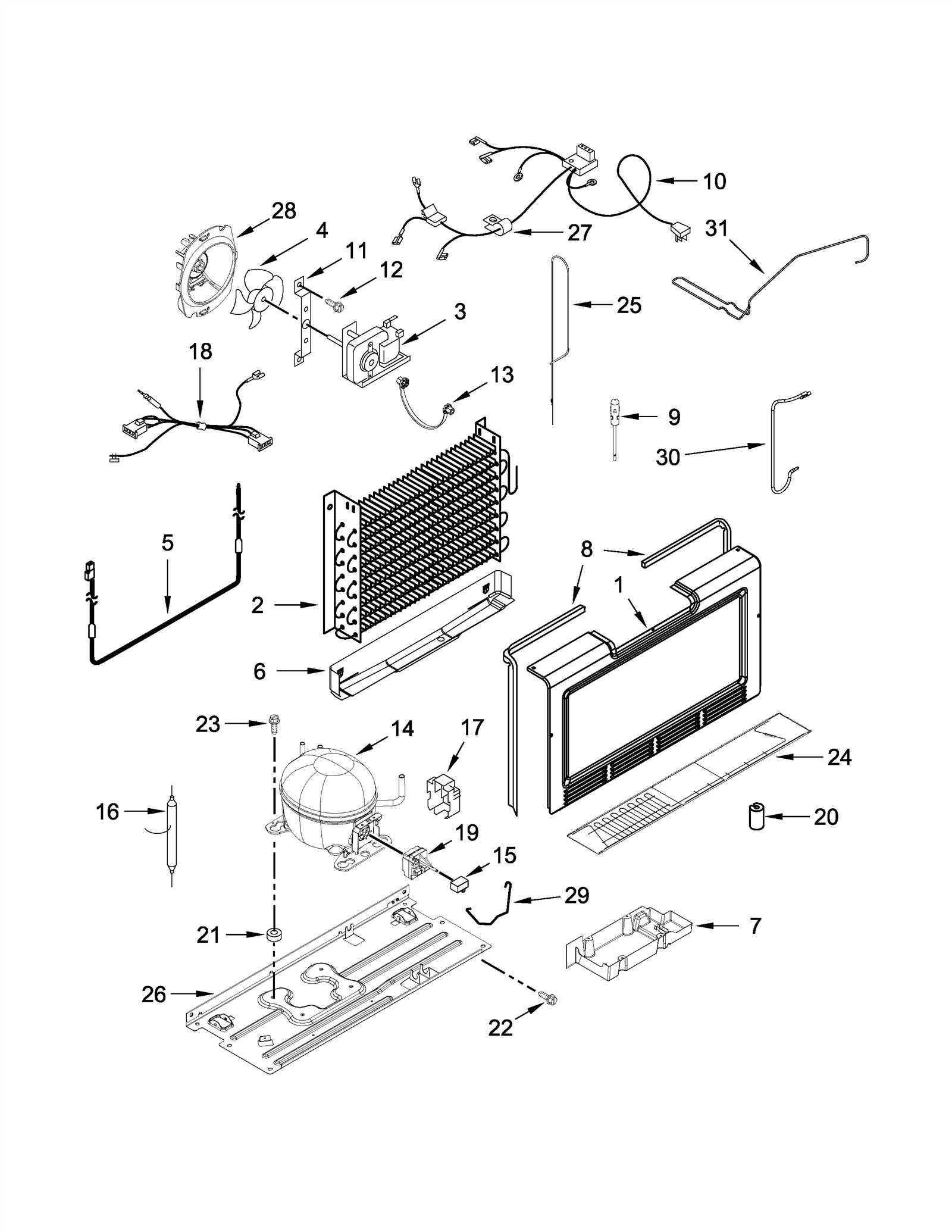

Key elements typically found inside the unit include compressors, condensers, evaporators, and thermostats. The compressor circulates refrigerant through the system, while the condenser helps expel heat. Evaporators are responsible for absorbing heat from the interior, and thermostats regulate the overall temperature. Each of these components must function properly for the system to operate as intended.

Recognizing the function of each part can aid in identifying potential issues and resolving them more efficiently. By understanding the layout and interaction of these components, users can better maintain their units and address problems before they escalate. Knowledge of the components also ensures that users are better prepared for repairs or replacements when necessary.

How to Read a Cooling Unit Schematic

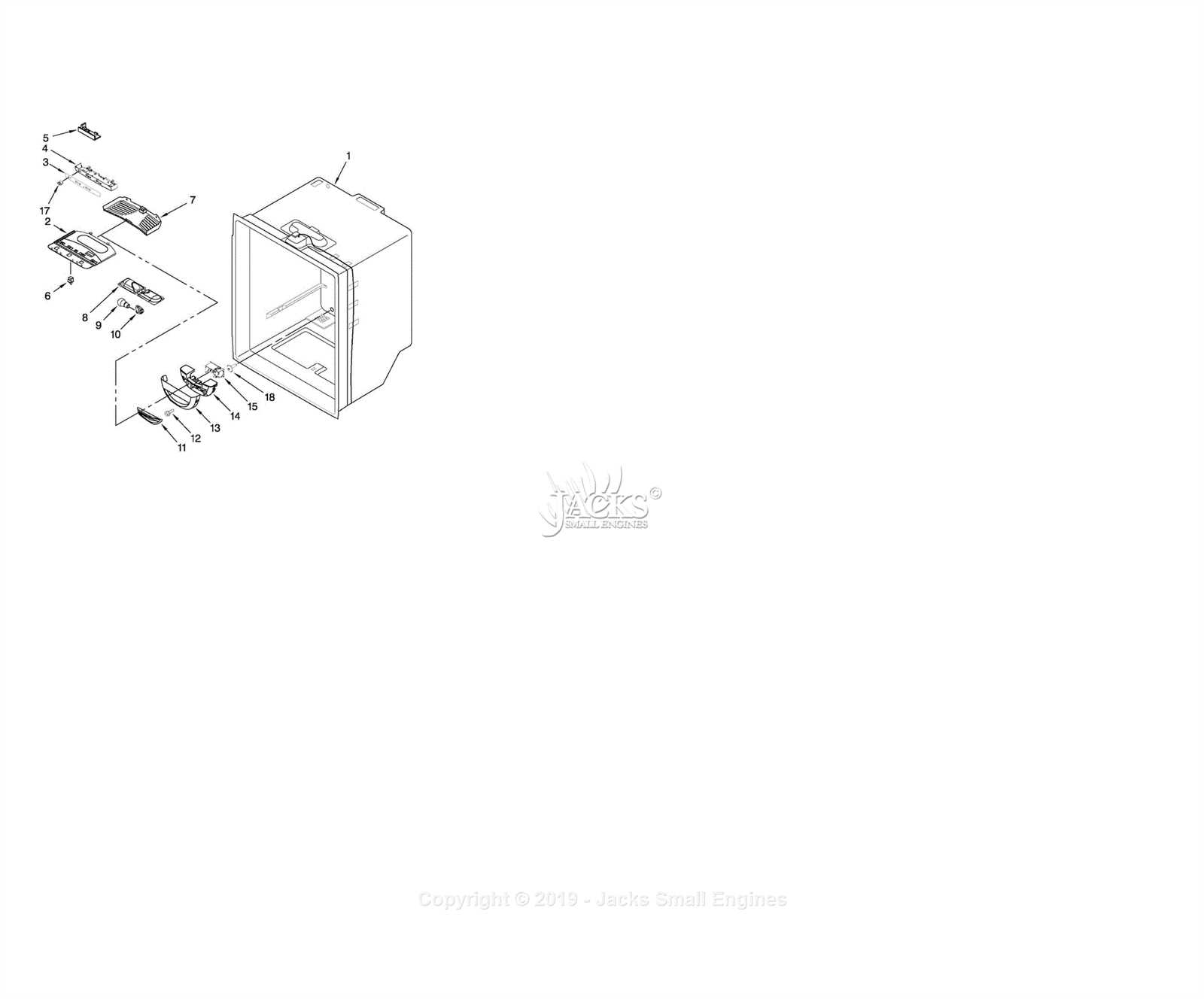

Interpreting a schematic can seem challenging at first, but once familiarized with the symbols and layout, it becomes a helpful tool for understanding the structure of your appliance. These schematics provide a visual representation of the internal elements and their connections, allowing users to identify components and their functions within the system.

To read a schematic effectively, start by familiarizing yourself with the legend or key that explains the symbols used. Each symbol represents a different component, such as the compressor, evaporator, or thermostat. The lines connecting these symbols indicate the flow of energy or refrigerant through the system, highlighting how components interact with each other.

Once you understand the symbols and connections, you can easily pinpoint the location of each component within the unit. This knowledge helps when troubleshooting or replacing faulty parts, ensuring you know exactly where to focus your attention. Properly interpreting the schematic can save both time and money during repairs.

Troubleshooting Cooling Unit Issues

When your appliance isn’t performing as expected, diagnosing the issue can often seem daunting. However, many common problems can be easily identified with a step-by-step approach. By understanding the key components and their functions, you can quickly pinpoint the cause of the malfunction and take the necessary steps to resolve it.

If your device is not cooling properly, start by checking the thermostat settings to ensure they are correctly adjusted. If the temperature remains high, inspect the compressor and condenser coils for dirt or blockages, as these can affect the unit’s ability to expel heat. Additionally, make sure the door seals are intact, as air leaks can compromise performance.

Another common issue is the accumulation of ice or frost, which can prevent airflow. If this occurs, it may indicate a problem with the defrost system or evaporator coils. In some cases, it could also be related to a faulty fan motor. By systematically addressing these potential problems, you can often solve the issue without needing to call a technician.