When using a specialized heating device for various tasks, it is essential to know how each component contributes to its overall functionality. Every piece works together to ensure efficiency and safety, making understanding the device’s structure vital for both beginners and experienced users.

The internal mechanism involves several key elements that control flame intensity, fuel distribution, and overall durability. Identifying and understanding these components will help in proper maintenance and troubleshooting, ensuring optimal performance during use.

By gaining insight into the individual roles of each element, you can effectively use and maintain the tool. Proper care can extend its lifespan and enhance the precision of tasks like soldering or light welding.

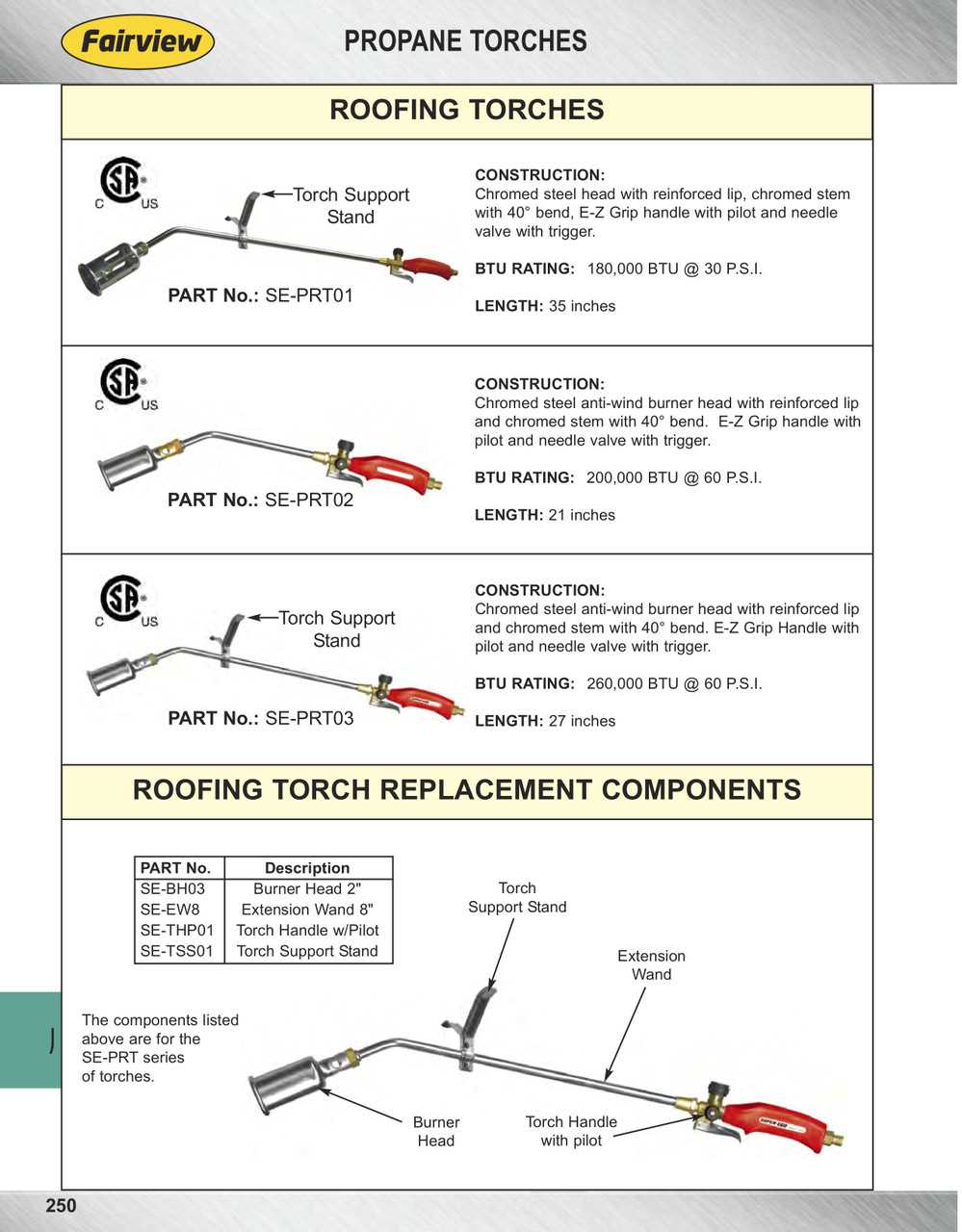

Key Components of a Heating Tool

Every high-heat device relies on a combination of specialized elements working together to provide consistent and controlled heat. Each individual piece plays a vital role in creating, regulating, and directing the heat for various tasks, ensuring precision and safety throughout the process.

The main components consist of the fuel delivery system, ignition mechanism, and the flame control system. Together, these features allow the user to easily adjust the intensity and focus of the heat, making the tool versatile for different applications such as soldering, brazing, or light metalwork.

Fuel and Flow Regulation

The flow of fuel is essential for efficient operation. This system regulates the amount of energy fed into the device, allowing users to manage the strength of the flame. Controlling this flow ensures safe and steady operation, preventing excess fuel buildup and maintaining a consistent heat output.

Ignition and Flame Control

Once fuel reaches the burner, the ignition mechanism activates to initiate the heating process. Flame control mechanisms allow the user to fine-tune the output, ensuring a steady, focused flame for precision work. This control can be adjusted based on the requirements of the task at hand, such as the need for higher or lower temperatures.

How to Identify Heating Tool Components

Recognizing the key elements of a high-heat device is crucial for understanding its functionality and maintenance. By familiarizing yourself with each component, you can ensure proper operation and troubleshoot any issues effectively. This process involves both visual identification and understanding the role each part plays in the overall performance of the tool.

Common Components and Their Functions

There are several common components that users must be able to identify when working with a heating tool. These include the fuel delivery mechanism, ignition system, and adjustment features. Below is a table outlining these components along with their primary functions:

| Component | Function |

|---|---|

| Fuel Valve | Controls the flow of fuel to the burner |

| Ignition Button | Initiates the flame when triggered |

| Flame Adjustment Knob | Regulates the intensity of the flame |

| Burner Tip | Focuses the heat at the desired point |

Steps to Identify Key Components

Start by visually inspecting the tool and identifying the main functional elements. Check the body for the fuel valve, which will often be located near the base, and locate the ignition button near the tip. By adjusting the flame control and observing how the flame changes, you can confirm the function of each mechanism. Understanding these components will help you use the tool safely and effectively.

Understanding the Function of Each Component

Each element in a high-heat device plays a critical role in ensuring that the tool operates efficiently and safely. Understanding the function of every component allows users to make the most of the tool’s capabilities, maintain it properly, and address any potential issues that arise during use.

The fuel delivery system is responsible for supplying the necessary fuel to the burner, regulating its flow to create a consistent flame. The ignition mechanism activates when needed, producing the spark that ignites the fuel. Meanwhile, the flame control system adjusts the strength of the heat, giving the user flexibility to achieve the desired intensity for different tasks.

By comprehending the function of each element, users can troubleshoot effectively, manage fuel consumption, and adjust settings for different applications. Whether using the device for soldering, brazing, or another purpose, knowing how each part contributes to the overall performance will ensure optimal results and longevity of the tool.

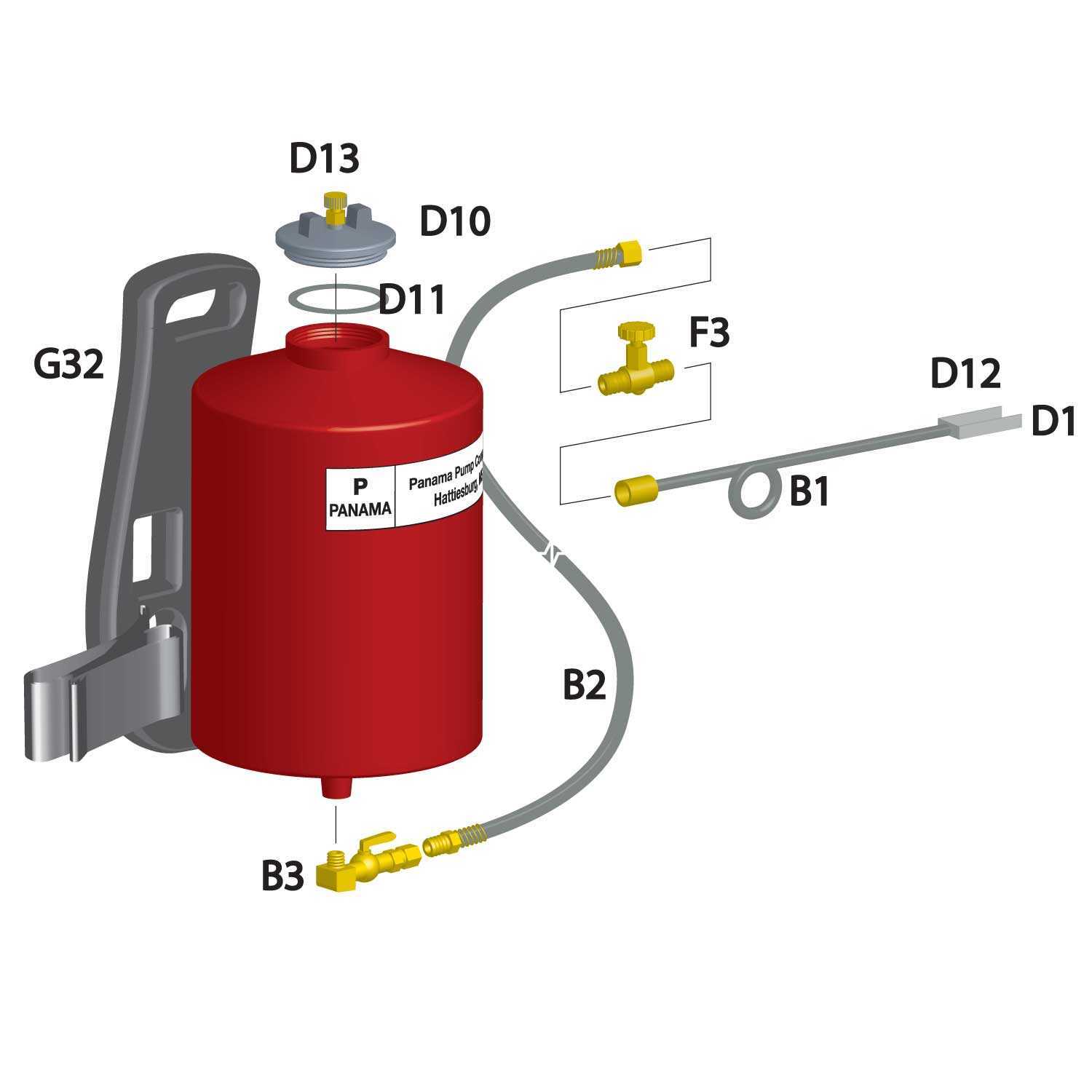

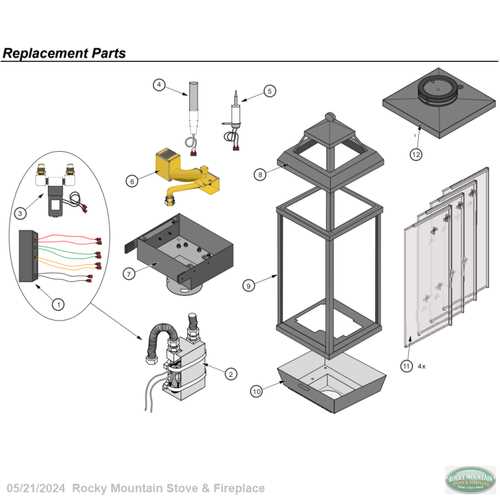

Detailed Diagram of Tool Assembly

Understanding how a heating device is assembled is crucial for proper use and maintenance. The layout of each component in the tool affects its overall functionality, ensuring that it operates smoothly and efficiently. By exploring the assembly, users can gain a deeper insight into how each part works together to create controlled heat for various tasks.

Key Assembly Components

The assembly consists of several primary sections, such as the fuel inlet, ignition system, and flame control mechanisms. These elements are interconnected to ensure a seamless flow of energy, allowing the user to produce the necessary heat. Each section has its own specific role, but they rely on one another for overall effectiveness and precision during use.

How Components Interact

When fuel enters the system, it is directed toward the burner tip, where ignition occurs. The flame control mechanism then adjusts the strength of the flame based on the user’s preference. The precise interaction between these parts allows for both safety and performance, ensuring that the tool is ready for a wide range of applications.

Regular maintenance of your high-heat device is essential for ensuring its longevity and consistent performance. Proper care not only keeps the tool functioning smoothly but also enhances its safety during use. A well-maintained device will be more efficient, reliable, and safe for various tasks over time.

Steps for Effective Maintenance

- Clean the Burner Tip: Periodically check the burner for any debris or build-up. Cleaning it ensures a consistent flame and prevents clogs.

- Inspect the Fuel Valve: Ensure that the fuel delivery mechanism is free from leaks. Regular inspection helps avoid safety hazards.

- Check the Ignition System: Make sure the ignition mechanism is working correctly. Replace worn parts to ensure a smooth start every time.

Additional Care Tips

- Store the device in a dry, cool place to prevent rusting or damage.

- Test the device before each use to ensure that all components are functioning properly.

- Always use the recommended fuel to avoid performance issues or damage to the internal mechanisms.