For those involved in agricultural machinery, a clear understanding of the various elements and their functions is essential for proper maintenance and effective use. Knowing how each part interacts ensures the equipment runs smoothly, preventing downtime during the crucial planting seasons. A well-maintained system can significantly boost productivity and extend the life of the machine.

Exploring the intricate design and layout of the machine helps in identifying potential issues early. The precise arrangement of components is not only essential for performance but also for ease of repair when necessary. Familiarity with how each segment fits into the bigger picture provides operators with confidence in their ability to troubleshoot or perform necessary upgrades.

Proper guidance in understanding these key aspects is vital for any operator looking to optimize their machine’s functionality. A comprehensive view of the structure, along with its individual pieces, allows for a more informed approach to maintenance and repairs, minimizing costly delays and maximizing efficiency in the field.

Understanding the Machinery Structure

When it comes to agricultural machinery, the overall design and construction play a crucial role in its efficiency. The way various components are organized and interact ensures that the system works seamlessly, providing consistent results in the field. A deep understanding of this structure helps operators optimize their equipment’s performance and address any issues that arise during use.

The machine’s framework is composed of several interconnected systems, each serving a specific purpose. From the drive mechanism to the seed placement unit, each part is designed to contribute to the overall function of the equipment. Knowing how these elements fit together provides valuable insight into how the entire machine operates, making it easier to identify areas for improvement or repair.

Familiarity with the layout not only aids in better maintenance practices but also empowers operators to troubleshoot potential problems effectively. When each part is understood in relation to the others, the operator can approach repairs with confidence, ensuring that downtime is minimized and efficiency is maximized during planting seasons.

Key Components and Their Functions

Understanding the core elements of any agricultural machine is vital for its effective operation. Each component serves a specific role, and their seamless interaction ensures the machinery performs as intended. From seed metering to soil preparation, these elements are designed to work in harmony, making it crucial for operators to be familiar with their functions for optimal usage and maintenance.

Drive and Power Mechanisms

The drive system is the backbone of the machine, providing the necessary power to move and operate the various mechanisms. It includes the motor, transmission, and wheels, each working in unison to propel the unit forward. The power system also ensures that other components, such as the seed dispenser and soil preparation tools, receive the energy needed for their functions. A well-maintained drive mechanism ensures consistent operation and prevents disruptions in the field.

Seed Placement and Distribution Units

Efficient seed placement is essential for a successful planting process. The seed distribution units are designed to accurately meter and deposit seeds into the soil at the right depth and spacing. These units are crucial for ensuring uniform germination and optimal crop growth. Regular checks and maintenance of these components are necessary to avoid issues like clogging or inaccurate seed spacing, which can negatively impact yield.

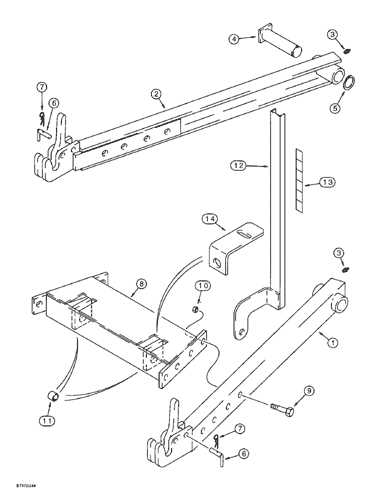

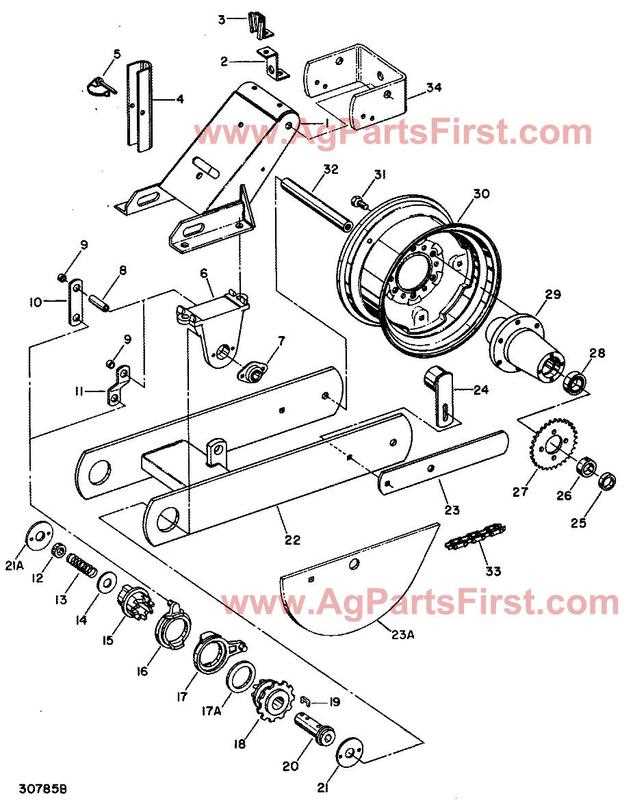

How to Interpret the Parts Diagram

Interpreting the layout of a complex machine can be a challenge without a clear guide. A visual representation of the system provides insight into how each element fits into the larger structure, allowing for easier identification of components and their functions. Understanding these illustrations can significantly enhance maintenance tasks and troubleshooting, making it an essential skill for operators and technicians alike.

Focus on component labels to identify each part’s name and its connection to other systems. These labels help differentiate the various mechanisms, from the drive system to the seed placement units, and provide context for understanding their interactions. Annotations, such as arrows or highlighted areas, often indicate the flow of energy or material, aiding in a better understanding of the overall process.

Pay attention to the arrangement and scale of the components. Recognizing how parts are organized within the diagram can help you visualize their placement in the real-world machinery. This is especially useful when performing maintenance or repairs, as it allows you to locate the exact part you need to inspect or replace. Understanding the relationship between different sections of the machine is key to resolving issues efficiently.