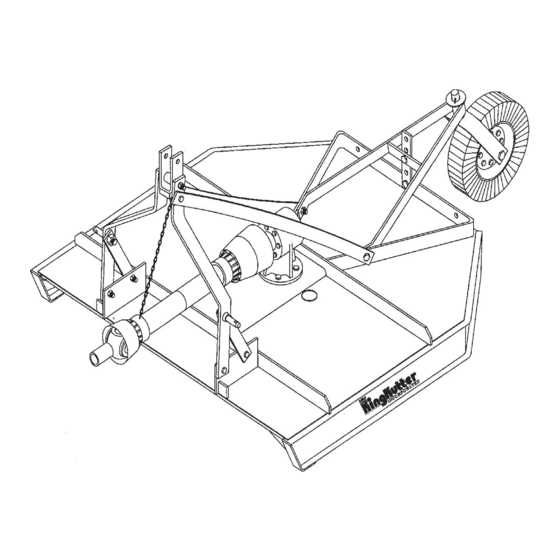

When maintaining large outdoor spaces, it’s essential to understand the machinery used for cutting and trimming. The performance of these tools relies on how well their individual elements function together. Identifying each crucial component and how they interact can significantly impact your maintenance routine.

Efficient operation requires knowing which parts work best and how to troubleshoot common issues. Each element serves a distinct purpose, whether for cutting precision or overall durability. Proper maintenance not only ensures better performance but also extends the lifespan of your equipment.

Learning the layout of the tool’s structure can help prevent breakdowns and unnecessary repairs. With the right knowledge, users can tackle both routine maintenance and more complex repairs with confidence, enhancing overall productivity and reducing downtime.

Key Components of a Lawn Cutting Machine

To ensure optimal performance, it is essential to understand the main elements that work together to make a cutting tool effective. Each component plays a specific role, contributing to the overall efficiency and durability of the equipment. Recognizing these key elements allows users to perform routine maintenance and repairs more effectively.

Understanding the Crucial Elements

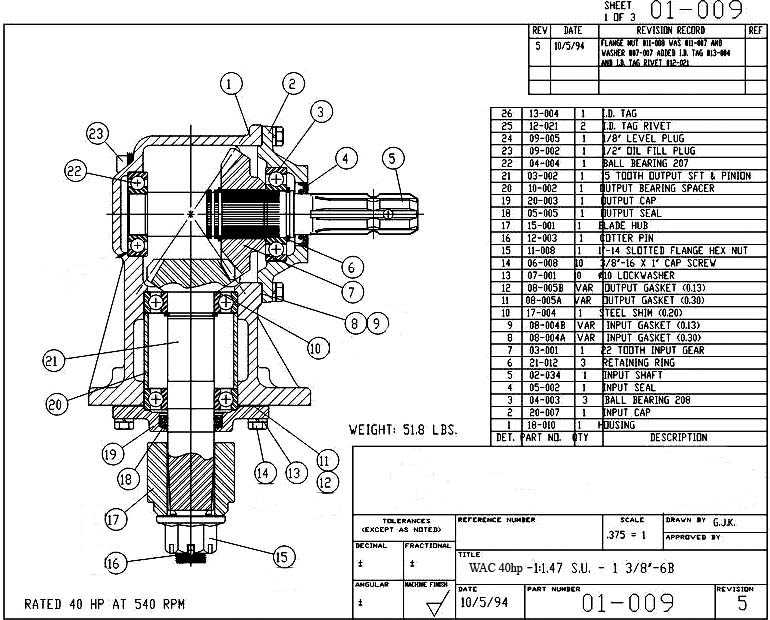

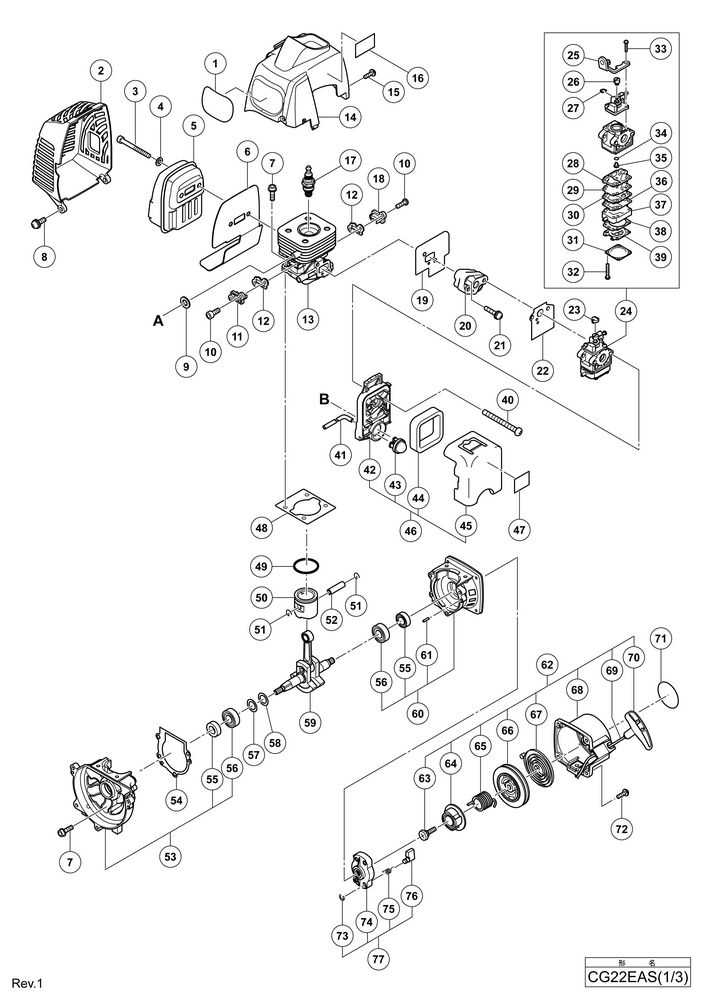

These tools consist of various crucial components, each with a designated function. The blade assembly is responsible for cutting through tough materials, while the transmission system ensures power is delivered effectively. The drive system is another vital part, converting energy to movement. Knowing how each piece interacts helps maintain smooth operation.

Essential Elements in Focus

Key components work in harmony to ensure seamless operation. Some of the most important parts include the power source, the cutting mechanism, and the safety features. Each piece requires attention during maintenance to prevent premature wear or malfunction.

| Component | Function |

|---|---|

| Blade Assembly | Responsible for cutting through grass and other vegetation. |

| Drive System | Transmits power to the cutting mechanism for movement. |

| Transmission | Transfers power from the engine to the drive system and cutting blades. |

| Power Source | Provides the necessary energy to operate the machine. |

How to Identify Each Part in the Diagram

Understanding how to recognize and locate each component within the equipment layout is vital for proper maintenance and troubleshooting. The visual representation of the machine shows the position and function of each part, making it easier to identify issues and perform repairs. A clear understanding of each part’s location simplifies the process of diagnosing problems and replacing worn elements.

Begin by looking for the most prominent features, such as the cutting blade or power system. Once familiar with these main components, it becomes easier to identify smaller, supporting parts like fasteners, belts, and springs. By carefully examining the layout, users can determine which part needs attention and how to proceed with repairs or maintenance tasks.

It’s important to study the diagram closely to understand how each element interacts with others. This ensures that any replacement or adjustment is done correctly, avoiding potential damage and improving the efficiency of the machine.

Common Issues with Lawn Equipment Components

While lawn tools are essential for efficient maintenance, certain components often face wear and tear over time, leading to common operational issues. Understanding these challenges allows users to address them promptly, ensuring the equipment continues to function properly and minimizing downtime. Several parts of the machinery are more prone to problems than others, but regular inspection and maintenance can prevent major failures.

Frequent Problems with Key Elements

The following issues are commonly encountered in lawn maintenance tools:

- Blades becoming dull – Dull cutting edges reduce performance and can cause uneven cuts.

- Power loss – Issues with the power system can prevent the machine from starting or running efficiently.

- Transmission failure – A malfunctioning transmission can lead to poor movement or a complete lack of motion.

- Excessive vibration – Loose parts or imbalance in the system can lead to excessive shaking, affecting the machine’s stability.

Identifying and Fixing Malfunctions

To avoid further damage, it is crucial to detect and address these problems early:

- Inspect the blade regularly for sharpness and signs of damage.

- Ensure all connections are tight and free from debris.

- Check the power source and transmission for any signs of wear.

- Balance moving parts to reduce vibration.

Steps to Maintain and Replace Parts

Regular maintenance and timely replacement of worn components are essential for the longevity and efficiency of lawn equipment. Proper care ensures that each element functions optimally and helps avoid unexpected breakdowns. By following a few simple steps, users can keep their machines in peak condition and reduce the need for costly repairs.

Routine Maintenance Tasks

To keep the equipment running smoothly, follow these maintenance practices:

- Clean regularly: Remove dirt, grass, and debris from all components to prevent build-up that can cause blockages or damage.

- Inspect for wear: Check all moving parts for signs of wear, such as fraying belts or cracks in the frame.

- Lubricate moving parts: Apply the appropriate lubricant to reduce friction and wear, especially in high-contact areas.

- Replace filters: Regularly change air and fuel filters to maintain engine efficiency.

Replacing Worn Components

If a component is damaged or shows signs of significant wear, follow these steps for replacement:

- Power off: Always turn off the engine and disconnect the power source before performing any replacement.

- Remove the faulty component: Loosen fasteners or use the necessary tools to carefully remove the worn part.

- Install the new component: Align the new piece in place and securely fasten it according to the manufacturer’s guidelines.

- Test the equipment: After replacement, start the machine and test it to ensure the new part functions correctly.

Understanding the Importance of Each Part

Each element of a lawn tool plays a crucial role in ensuring its effective operation. From the power source to the cutting mechanism, every part works together to deliver the desired results. Recognizing the function of each component is vital for proper maintenance, as neglecting any part can lead to inefficiency or potential damage. Understanding how each piece contributes to the overall system helps users care for their equipment more effectively.

Key Components and Their Roles

Some parts are directly involved in cutting or movement, while others ensure the machine runs smoothly and efficiently. For instance, the engine or motor is the heart of the tool, providing the power needed for operation. The transmission and drive system distribute that power, enabling the cutting mechanism to function. Each supporting element, such as belts or safety features, ensures the equipment’s longevity and user safety.

Why Proper Care Matters

Maintaining each part’s condition is essential for achieving optimal performance. Regular checks and repairs prevent breakdowns and improve the overall lifespan of the equipment. By addressing the needs of each component, users can avoid costly replacements and extend the machine’s efficiency.