Proper understanding of the individual components of your garden equipment is essential for efficient operation and long-term durability. Regular inspection and repair can prevent unnecessary breakdowns and ensure your tools are ready for use when needed most. Whether you’re a hobbyist or a professional, knowing how to maintain and troubleshoot your machine will help you get the best performance out of it.

Detailed visuals and explanations can assist in recognizing each element of the machine, from the engine to the working mechanisms. With this knowledge, you can confidently address any issues that arise and perform necessary repairs yourself, saving both time and money.

Familiarizing yourself with the internal structure not only enhances your understanding of how everything functions together but also equips you with the skills to replace or adjust components. In this guide, we will walk you through a complete overview of your equipment’s essential parts, offering insight into their role and maintenance tips to keep everything running smoothly.

Understanding the Components of Your Garden Equipment

Every mechanical tool consists of various elements that work together to deliver optimal performance. Understanding these individual components will allow you to maintain and repair your machine with confidence. Knowing how each part interacts ensures that you can spot potential issues early and take proactive steps to prevent malfunctions.

Key Elements of Your Machine

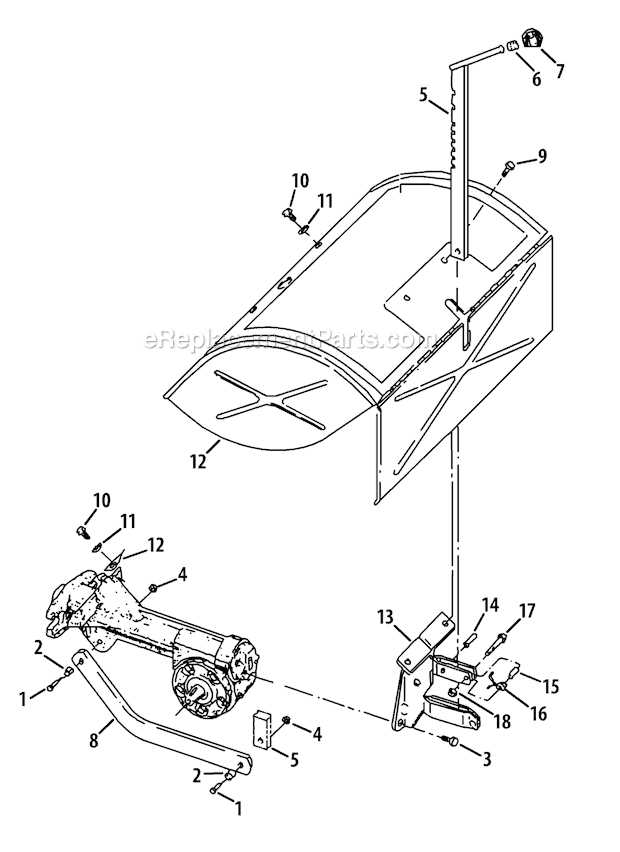

At the core of any outdoor machine lies a powerful engine, which is responsible for providing the necessary force to operate the other mechanisms. Around this engine, you’ll find belts, pulleys, and other moving parts that transfer energy to the various working parts. These elements are crucial for efficient operation, and their maintenance can significantly extend the life of your tool.

Maintaining the Internal Mechanisms

Regular inspection of internal components such as gears and shafts is necessary to ensure smooth operation. These elements are subject to wear and tear over time, especially with frequent use. Lubricating moving parts and replacing damaged components when needed will help keep everything functioning as intended. Additionally, understanding the location and function of each internal mechanism can help you perform repairs more accurately and efficiently.

How to Identify Key Machine Components

Recognizing the primary components of your garden tool is essential for effective maintenance and repair. Understanding which parts play crucial roles in the overall functionality helps to identify problems and address them promptly. By learning the names and functions of key elements, you can quickly pinpoint the source of any issues that arise.

Start by familiarizing yourself with the outer structure, which houses many of the key mechanisms. The engine is usually the most noticeable part, but beneath the surface, you’ll find several other important components, including transmission systems, belts, and drive shafts. Recognizing these elements will give you a better understanding of how they contribute to the operation of your equipment.

Once you identify the main components, you can begin examining how they interact with each other. For example, the drive system transfers energy from the engine to the wheels or other functional parts. Understanding this flow of power will make it easier to troubleshoot and determine what might be malfunctioning when something goes wrong.

Step-by-Step Repair Guide

Repairing your garden equipment doesn’t have to be daunting. With a clear understanding of the issue and the right approach, you can successfully address common problems and restore your machine to working order. Following a methodical, step-by-step process ensures that nothing is overlooked and all necessary actions are taken to fix the malfunction.

Diagnosing the Problem

Before diving into repairs, it’s important to accurately diagnose the issue. Start by observing the machine’s performance and listen for unusual sounds. Check for any visible signs of wear, damage, or disconnection. The engine, transmission, and drive systems are often the most common culprits when a machine isn’t operating as expected. Take the time to inspect each component carefully.

Performing the Repair

Once you’ve identified the faulty component, gather the necessary tools and replacement parts. For minor issues, such as a loose belt or worn-out spark plug, these tasks can typically be completed with basic tools. For more complex repairs, it may be necessary to consult a professional or refer to a detailed manual. Remember to follow safety guidelines and ensure the equipment is powered off before starting any repair work.

Common Fixes for Garden Equipment Models

Sometimes garden machines experience common issues that are easy to fix with a little knowledge and the right tools. Addressing these problems early can help maintain the performance and extend the lifespan of your equipment. Below are some of the most frequent issues owners face and simple fixes to resolve them.

Engine and Power Issues

If your machine isn’t starting or has power issues, the cause could be something simple. Here are a few common fixes:

- Check the fuel: Ensure the tank is filled with fresh fuel, as old or contaminated fuel can cause problems.

- Inspect the spark plug: A dirty or worn-out spark plug can prevent the engine from starting properly. Replace it if necessary.

- Clean the air filter: A clogged air filter can restrict airflow to the engine, reducing power and efficiency. Clean or replace it to ensure smooth operation.

Drive System Issues

Problems with the drive system can cause difficulty in maneuvering or even complete loss of movement. Here are some steps to troubleshoot:

- Inspect the drive belt: A loose or broken belt can disrupt power transmission. Tighten or replace the belt as needed.

- Check for obstructions: Make sure there are no rocks, debris, or other items blocking the drive mechanism.

- Lubricate moving parts: Regular lubrication of gears and shafts ensures smooth movement and reduces wear.

Maintenance Tips for Long-lasting Performance

Regular maintenance is essential to keep your equipment running efficiently and prolong its lifespan. By performing routine checks and addressing small issues before they become major problems, you can ensure that your machine delivers optimal performance year after year. This section outlines key maintenance practices that every owner should follow.

Routine Care and Inspections

To prevent unexpected breakdowns and ensure reliable operation, it’s important to inspect your machine periodically. Regular checks help catch potential issues early and keep your equipment in top condition. Below is a table summarizing the main maintenance tasks and how often they should be performed.

| Task | Frequency |

|---|---|

| Change oil | Every 50 hours of use |

| Clean or replace air filter | Every 25 hours of use |

| Check and tighten belts | Every 25 hours of use |

| Inspect spark plug | Every 50 hours of use |

| Grease moving parts | Every 25 hours of use |

Seasonal Maintenance

Seasonal maintenance ensures that your equipment is ready for use at the start of each season and performs well throughout. Before storing your machine for the offseason, take the time to clean it thoroughly, check fuel levels, and inspect for any wear. Proper storage and care during off months prevent damage and rust.