When it comes to repairing or maintaining machinery, knowing how each component fits into the overall structure is essential. Visual aids can provide a comprehensive view, offering clarity on how individual elements work together. These resources guide users through identifying the correct pieces, ensuring efficient repairs and maintenance.

Recognizing the layout of the entire setup helps users quickly understand the relationships between parts and their function. This approach saves time and minimizes errors by making each part’s role easier to grasp. It also highlights the correct sequence for assembly, which is critical for avoiding complications during repairs.

By following a well-organized visual representation, technicians can ensure they are using the right parts in the right places, which ultimately leads to smoother functioning and longer-lasting results. Such illustrations are invaluable for both novice and experienced professionals, providing a structured path to maintaining operational efficiency.

Understanding the System’s Layout

Efficient maintenance and repair require a clear understanding of how all the components in a machine are arranged and interact. A well-organized layout provides a roadmap for identifying and working with the various elements within the structure. This approach ensures that users can quickly assess the system, allowing for accurate troubleshooting and smooth repairs.

By studying a detailed representation of the system, individuals can easily pinpoint each part’s location and understand its function. This knowledge minimizes errors and optimizes the repair process, as it ensures that no part is overlooked or incorrectly handled. Recognizing the interconnections between components further improves efficiency and speeds up the overall maintenance process.

Having a visual reference for the system’s organization offers many advantages, particularly in terms of saving time and reducing potential damage. With a clear map of how everything fits together, users can confidently approach repairs, knowing they have the information they need at hand. This layout serves as an essential tool for anyone involved in maintaining or repairing the machine.

Essential Components of the System Layout

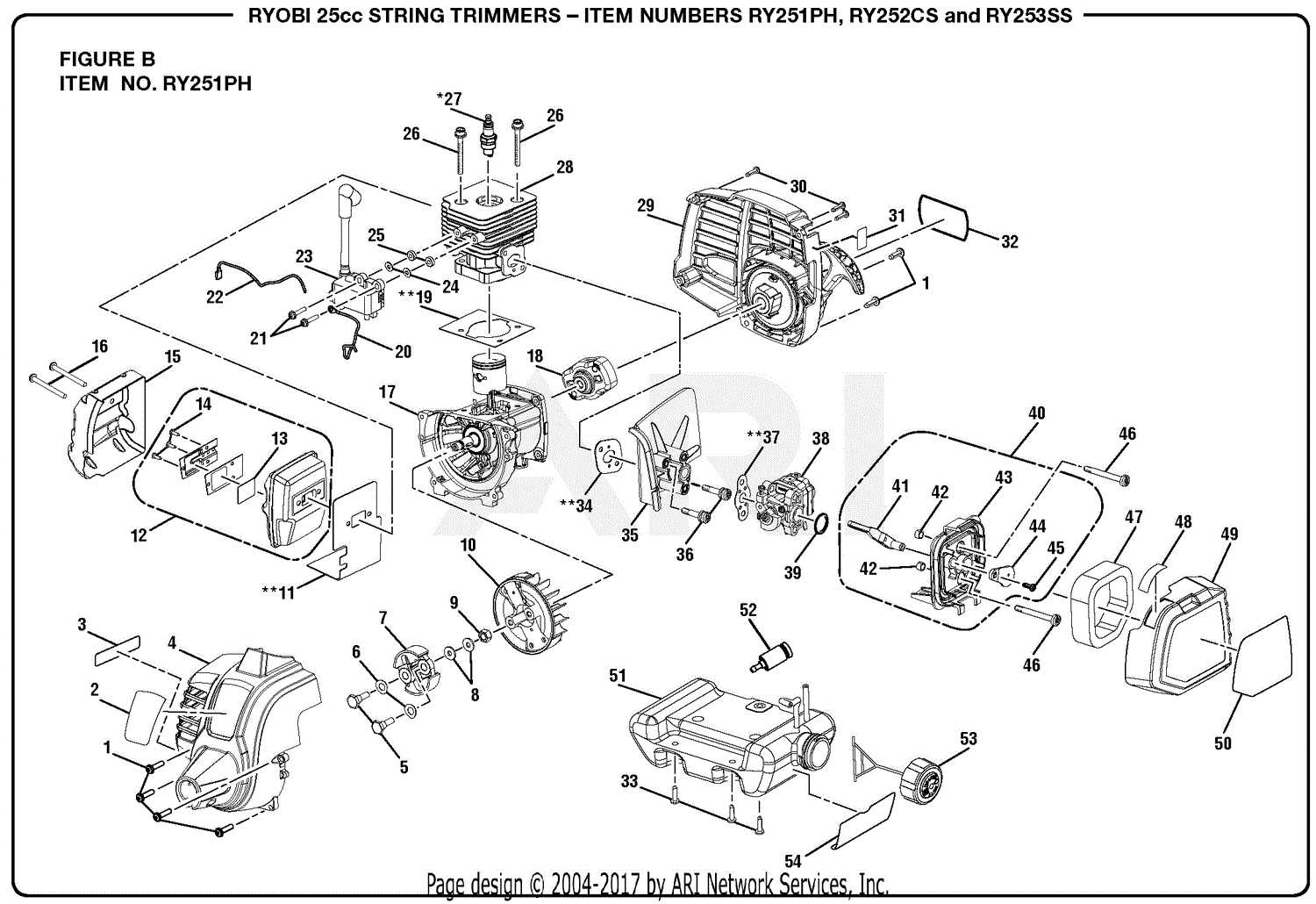

Every machine consists of key elements that work together to ensure smooth operation. Understanding these crucial components is necessary for effective maintenance and troubleshooting. By identifying each piece and its specific function, one can ensure the system performs optimally and lasts longer.

Main Functional Units

The core components that drive the functionality of the system are essential to its overall performance. These units serve specific roles, from providing power to enabling movement, and are integral to the system’s success. Without a clear understanding of these primary elements, diagnosing issues or making necessary adjustments becomes a challenge.

Supporting Components and Accessories

In addition to the main units, there are supporting elements that help maintain the structure and functionality. These include connectors, fasteners, and smaller accessories that ensure everything stays in place and functions as intended. Even though they may seem secondary, they play a vital role in maintaining the overall integrity of the system.

How to Interpret the System’s Layout

Interpreting a system’s visual representation requires attention to detail and understanding the information it conveys. A clear and accurate chart provides insights into the placement and connection of each element. Knowing how to read this layout effectively enables users to diagnose issues and identify parts that need attention quickly.

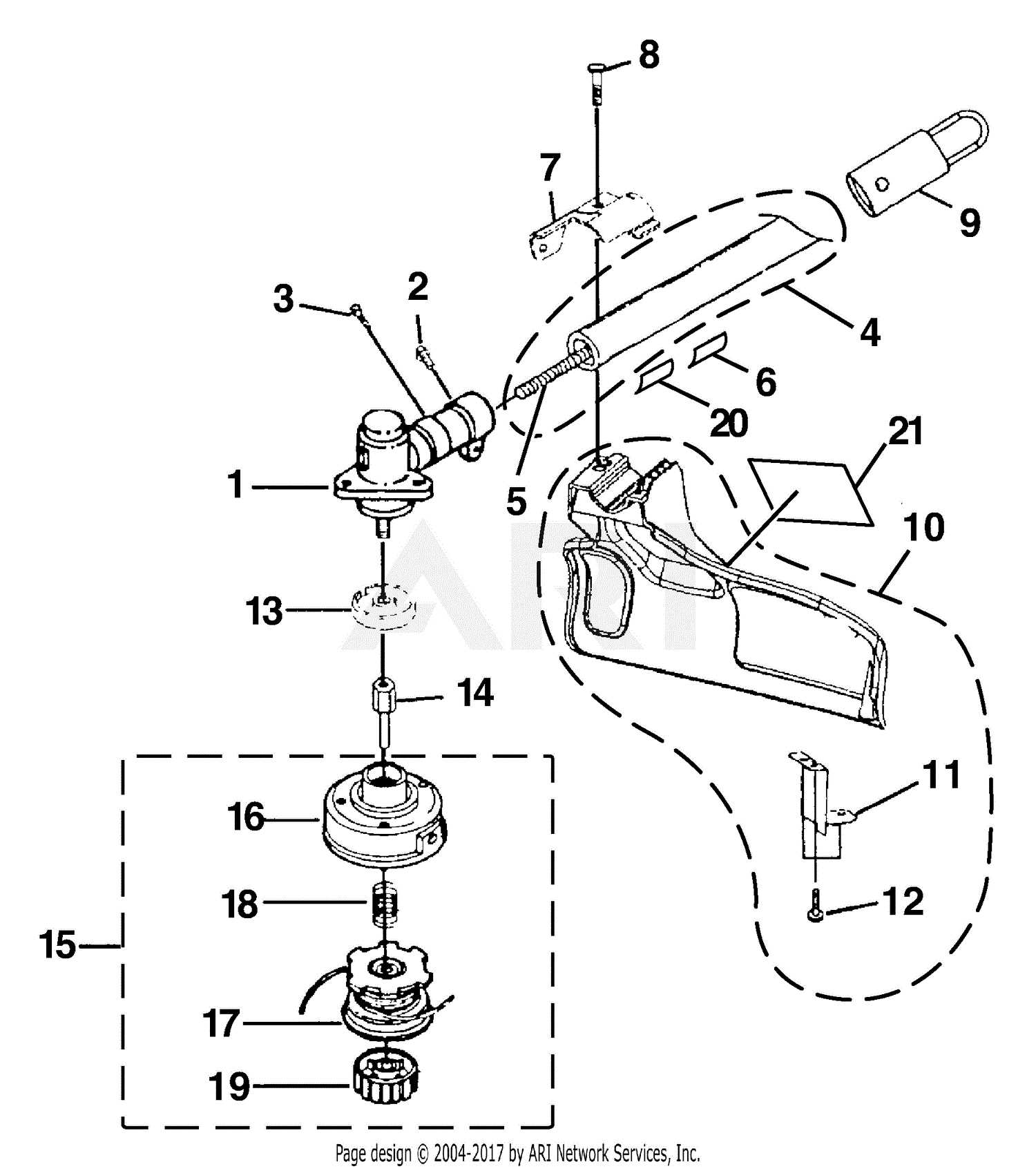

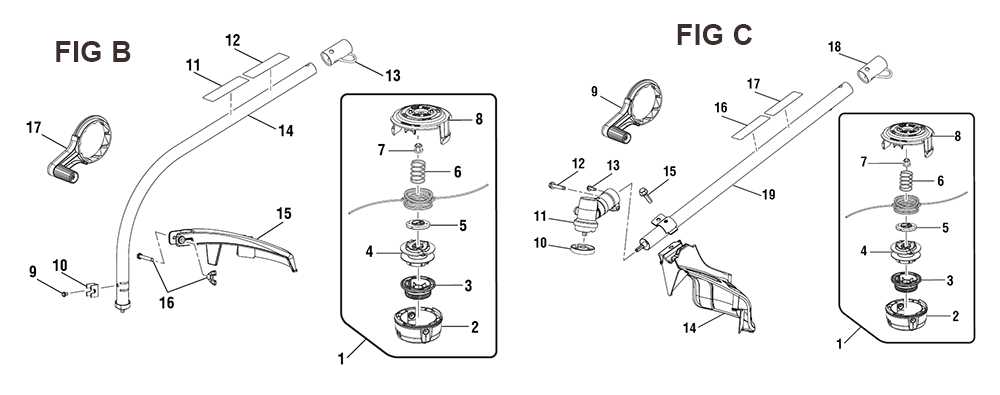

Reading the Labels and Markings

Most visual guides will include labels and symbols that correspond to specific components within the structure. It’s important to understand the meaning behind these markings, as they indicate everything from size and shape to the function of each element. Familiarizing yourself with these annotations allows for easier identification and proper handling of each part.

Understanding Component Relationships

In addition to individual elements, the chart also shows how components are interconnected. By following lines or arrows that indicate flow or connection, one can determine how parts influence each other’s function. This knowledge is crucial when troubleshooting or making adjustments, as it helps to pinpoint the exact location of potential issues.