Maintaining and repairing a lawn mower becomes much easier when you can identify and understand its individual components. This guide will help you recognize the key elements of a mower and offer practical tips on maintenance and replacements. Knowing how each part functions will ensure optimal performance and extend the lifespan of your equipment.

Understanding the structure of a lawn mower is crucial for both regular upkeep and troubleshooting common issues. With a clear view of the main elements, you can pinpoint where problems might arise and address them promptly. This approach saves time and effort, allowing you to perform repairs with confidence.

Each lawn mower consists of multiple sections that work together to ensure smooth operation. From the engine to the cutting mechanism, every piece plays a significant role. Whether you’re dealing with a malfunction or just need to replace a worn-out part, this guide will provide the necessary details to make informed decisions.

Understanding the Components of Your Lawn Mower

Every lawn mower is made up of several key elements that work together to deliver efficient performance. By understanding these components, you can enhance your maintenance skills and ensure your mower runs smoothly for longer. Familiarity with each part’s role helps you identify potential issues and take the necessary steps for repair or replacement.

Main Functional Elements

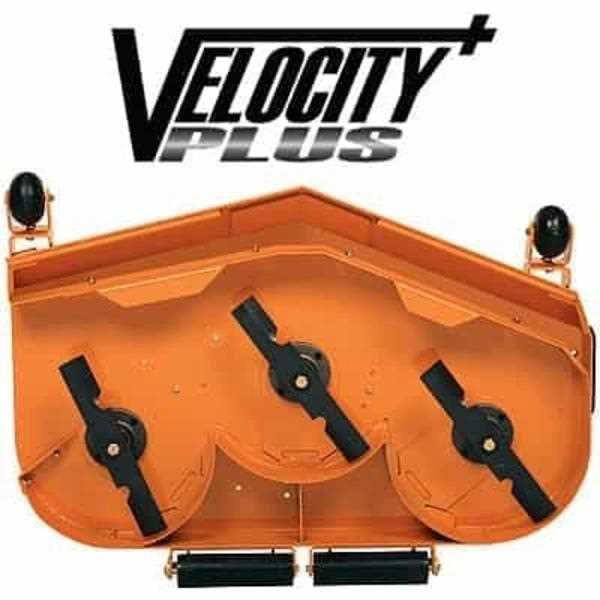

The engine serves as the heart of the machine, providing the power needed for all operations. In addition, the cutting mechanism, typically composed of rotating blades, ensures your lawn is evenly trimmed. These are only a few of the important sections that keep the mower functional, each playing a vital role in the overall efficiency of the equipment.

Common Maintenance Areas

Regular maintenance is essential for keeping the mower in top condition. Key areas to focus on include the belts, air filter, and fuel system. These parts are prone to wear and tear over time and may need replacement to prevent malfunction. By addressing these areas proactively, you can avoid more serious issues and extend the life of your machine.

How to Read the Component Layout

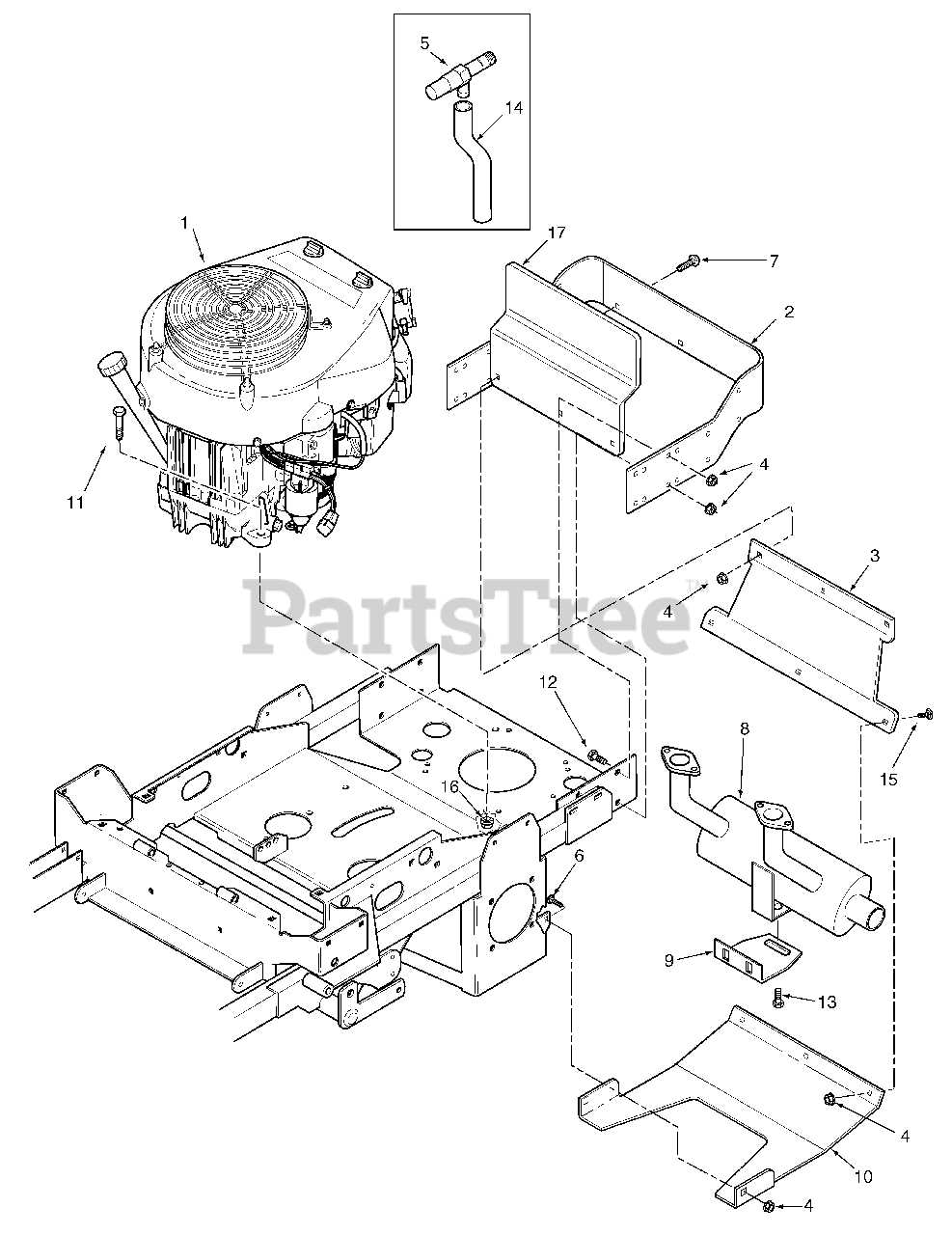

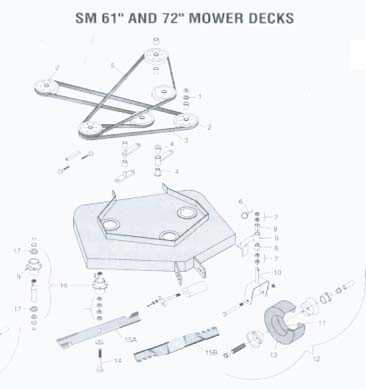

Interpreting the layout of a machine’s components is essential for understanding how its individual sections work together. A clear and organized schematic can guide you through the various elements, making it easier to identify specific parts and their functions. Knowing how to read these layouts is crucial for performing accurate repairs and replacements.

Each diagram typically uses numbers or labels to indicate the parts and their corresponding positions. Understanding the symbols and layout conventions allows you to pinpoint any issues and address them efficiently. Look for key markers that distinguish major sections, and refer to the provided legend or list for detailed descriptions of each component.

Common Issues and Replacement Components

As with any piece of machinery, certain issues may arise over time that require attention or part replacement. Understanding the most common problems can help you take preventive measures and ensure your equipment continues to operate at its best. By identifying and addressing these issues early, you can avoid costly repairs and extend the life of your machine.

One frequent issue is wear and tear on the cutting mechanism, which may require blade sharpening or replacement. Another common problem is damage to the drive belt, which can cause the machine to lose power or stop functioning. Regular checks on components like the fuel system, filters, and electrical connections are also recommended to prevent performance issues and maintain smooth operation.