Maintaining outdoor power tools is essential for ensuring their longevity and optimal performance. Having a clear understanding of each component and its function can make the maintenance process smoother and more efficient.

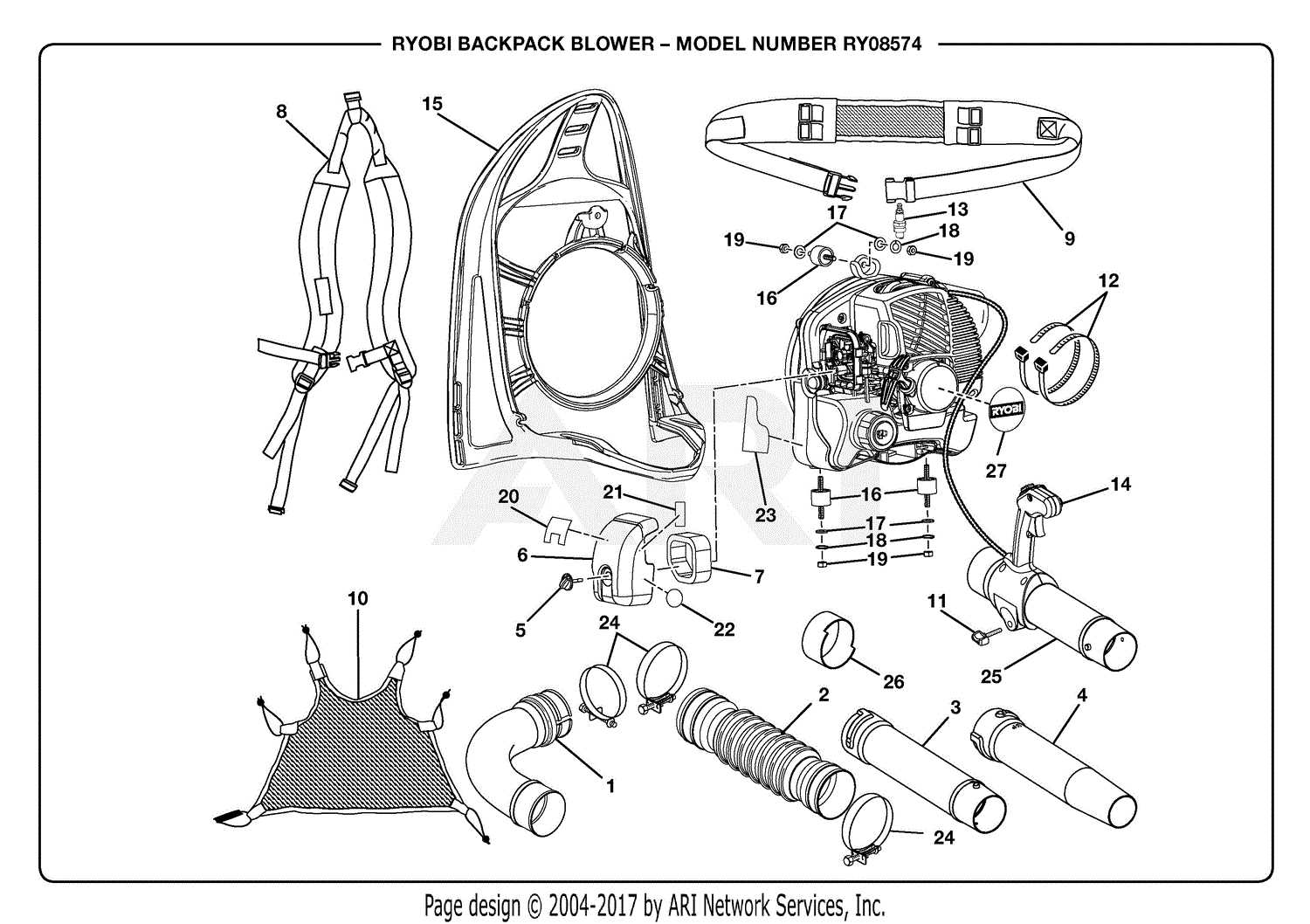

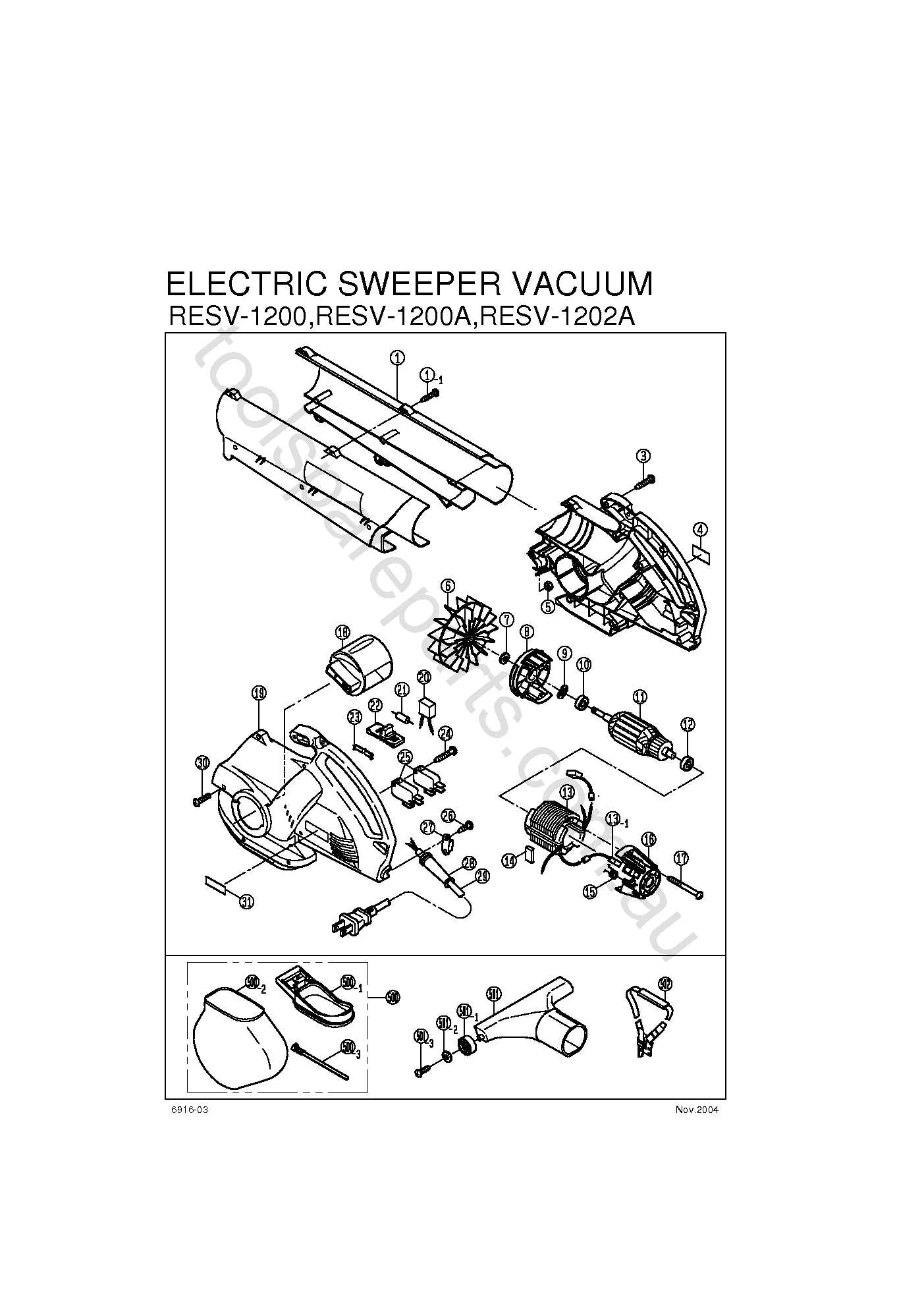

In this section, we will explore a detailed illustration that breaks down the internal structure of a popular model, offering valuable insights into each piece. Knowing how to properly identify, replace, and troubleshoot specific components will help users avoid unnecessary repairs and costly mistakes.

Whether you’re a beginner or a seasoned user, understanding the design and mechanics of your equipment is key to keeping it in top shape. With this guide, you’ll gain the confidence to handle basic repairs and ensure your tool operates as intended for years to come.

Understanding the Equipment Layout

Every mechanical tool consists of multiple elements that work in harmony to perform its intended functions. A clear overview of these individual components and their relationships can help users gain a deeper understanding of how the tool operates and how to maintain it effectively.

By carefully studying the layout, it becomes easier to identify key sections that require attention or replacement. The arrangement of these parts allows users to pinpoint specific areas of concern, streamlining the repair and maintenance process.

Familiarity with the design not only aids in repairs but also in troubleshooting any issues that may arise during use. Recognizing how each component interacts ensures that any modifications or replacements will not compromise the performance of the tool.

How to Identify Parts in the Illustration

Accurately identifying components within a tool’s schematic is crucial for effective maintenance and repair. Understanding how each part is represented in the visual guide helps users quickly locate and assess the specific pieces they need to work on.

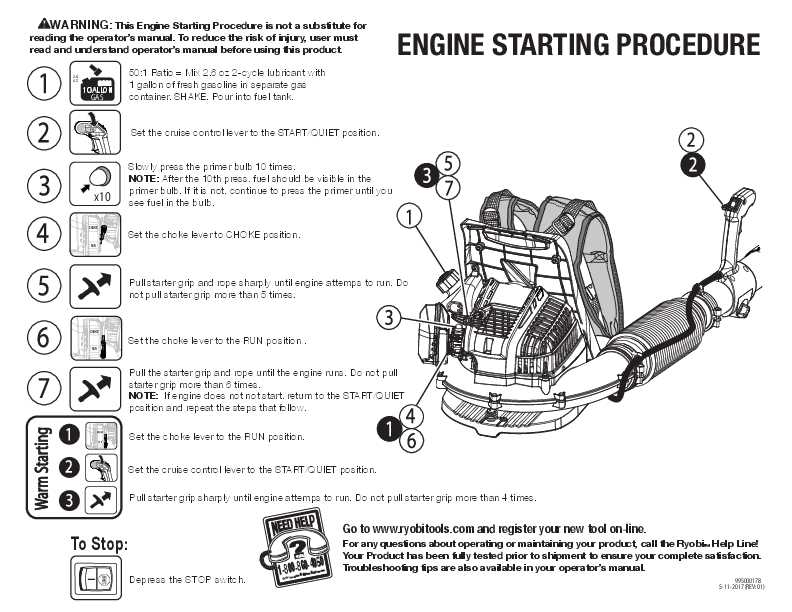

Step-by-Step Process for Identification

Start by reviewing the key labeled areas, which typically include a detailed breakdown of every significant element. Each component will be numbered or marked with unique identifiers, allowing you to correlate it with the manual or guide. Familiarity with the labels will enable easier navigation through the layout.

Helpful Tips for Efficient Identification

Pay attention to the shape, size, and placement of each part. These factors can often give away the function of the piece. Additionally, understanding the tool’s overall function will help you focus on the most relevant areas. With some practice, you will be able to quickly identify the exact component needed for replacement or inspection.

Tips for Replacing Equipment Components

Replacing worn or damaged components in your tool requires careful planning and attention to detail. Knowing when and how to replace specific parts can significantly extend the life of your equipment and maintain its performance.

Start by gathering all necessary tools and replacement pieces before you begin. Having everything on hand will make the process smoother and help avoid interruptions. Always ensure that you follow the correct procedure outlined in the manual to prevent damage to surrounding components.

When replacing a part, check for signs of wear on other nearby elements. Often, when one piece fails, others may show early signs of stress. Thoroughly inspect the area to ensure there are no hidden issues that could cause further problems down the line.