Maintaining your lawn equipment is crucial to ensure its longevity and optimal performance. Understanding how each component functions and fits together can save you time and effort when troubleshooting or performing repairs. This guide will help you gain a clearer understanding of the essential elements involved in maintaining your equipment.

Whether you are looking to replace worn-out components or assemble your machine from scratch, having a visual reference can make the task more manageable. With the right knowledge, you’ll be able to quickly identify issues and take the appropriate actions to resolve them, ensuring that your machine continues to perform at its best.

Understanding the Lawn Equipment Breakdown

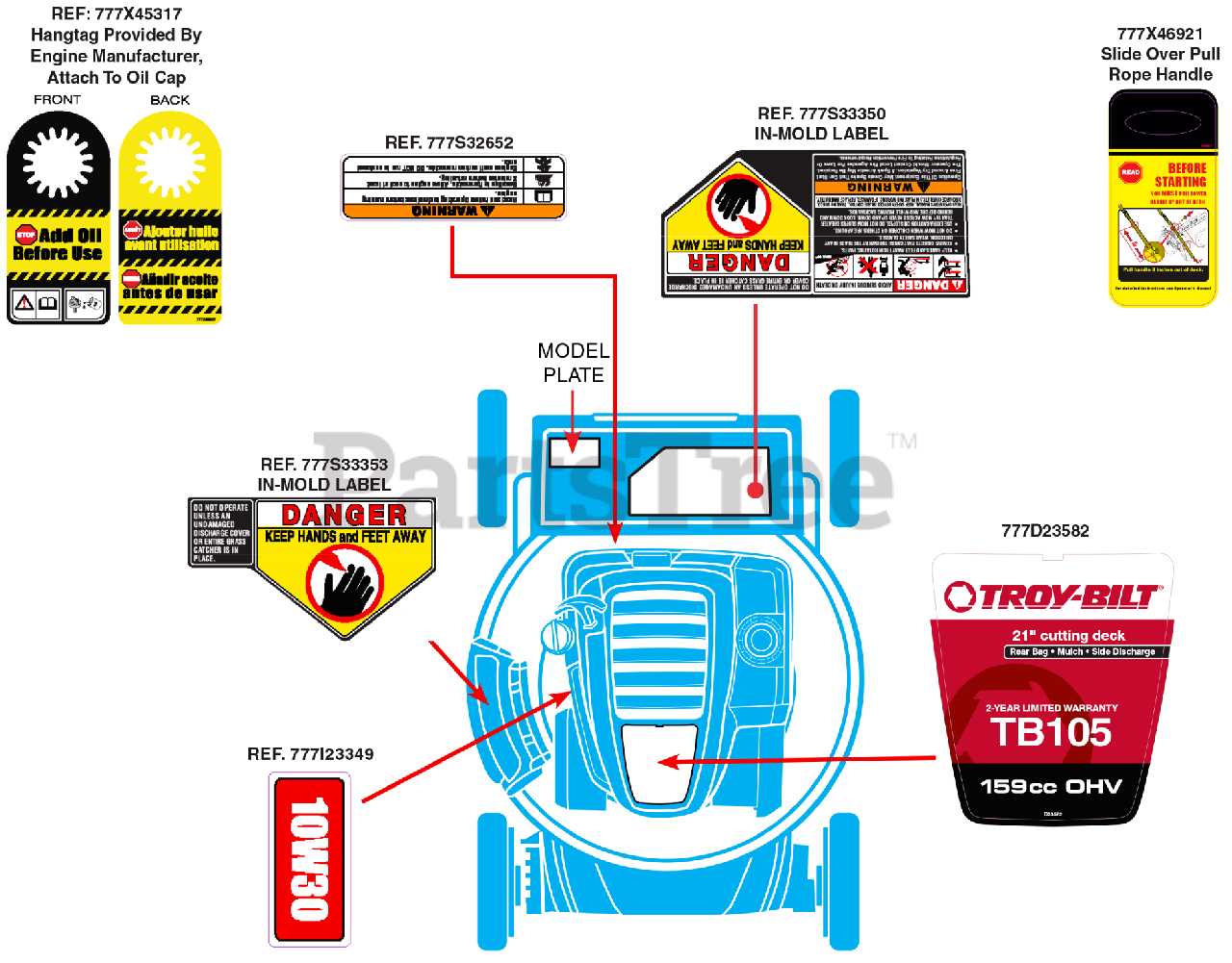

When working with mechanical devices, it’s essential to have a clear representation of how the individual components interconnect and function. A detailed schematic or breakdown allows you to visualize the machine’s structure, making it easier to identify each part and its specific role. This understanding is key to effective maintenance and repair.

By studying a well-illustrated guide, you can quickly familiarize yourself with the various elements of your machine. It not only helps in understanding the configuration of each component but also serves as a useful tool when ordering replacements or performing adjustments. Having a clear reference ensures that you can tackle repairs with confidence and accuracy.

How to Identify Key Parts

Accurately identifying the crucial components of your equipment is the first step in ensuring effective maintenance and repair. By recognizing the function and position of each element, you can avoid unnecessary confusion and make the right decisions when fixing or replacing parts. This process becomes significantly easier when you have a clear reference or visual guide to follow.

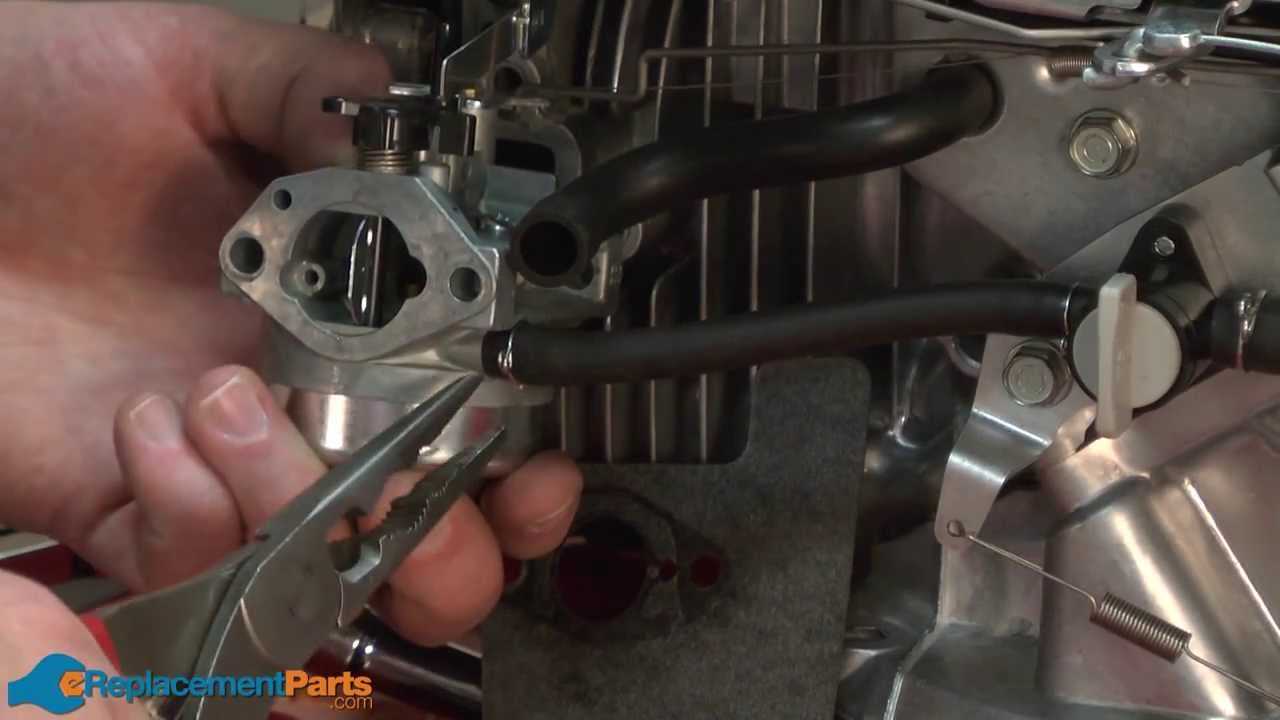

Step-by-Step Identification Process

Begin by reviewing the key features of the machine, such as the engine, drive system, and safety mechanisms. These elements are typically the most critical to the equipment’s operation. Ensure that you understand how each part interacts with others, as this knowledge will help you spot any issues quickly and accurately.

Commonly Replaced Components

There are certain parts that are more likely to require replacement due to wear and tear, such as belts, filters, and spark plugs. Identifying these parts early on can prevent more significant problems in the future. Familiarize yourself with these components so that you can replace them as needed without delay.

Steps for Efficient Part Replacement

Replacing worn or damaged components in your machine can significantly improve its performance and longevity. However, the process requires careful planning and execution to ensure the new parts are installed properly. Following a clear set of steps will help streamline the replacement process, saving you time and reducing the risk of further issues.

Prepare and Gather Necessary Tools

Before starting any replacement, make sure you have the proper tools and replacement components ready. This includes wrenches, screwdrivers, and any specific tools required for the task. Having everything at hand will prevent unnecessary interruptions during the process.

Follow Manufacturer Guidelines

It’s crucial to adhere to the manufacturer’s instructions or recommended procedures for replacing components. These guidelines will help ensure the parts are fitted correctly and safely. Referencing a schematic or guide can be helpful in ensuring accuracy during the process.