When using modern cleaning appliances, understanding their internal structure can greatly enhance maintenance and troubleshooting efforts. Knowing how each element interacts within the machine ensures a more efficient cleaning experience and prolonged lifespan. This section provides a clear breakdown of the essential components that keep your cleaning tool running smoothly.

By exploring the essential pieces that make up the inner workings of your equipment, you gain the ability to identify potential issues and replace worn-out elements with ease. With this knowledge, you can maintain peak performance and avoid costly repairs by handling minor problems before they escalate.

Whether you’re replacing a part or performing routine maintenance, understanding the functions of each piece is crucial for smooth operation. It’s time to become familiar with how your cleaning appliance is assembled to keep it in optimal condition.

Understanding Ryobi Stick Vacuum Components

Every modern cleaning device consists of various key elements that work together to ensure its functionality and efficiency. These components, from the power source to the brush mechanism, are designed to contribute to seamless performance. Understanding how these elements function individually and together allows you to troubleshoot issues and keep the machine running at its best.

The heart of any cleaning tool lies in its motor and power system, which provide the necessary energy for operation. Alongside it, other crucial pieces, such as the filtration system, suction components, and structural supports, play significant roles in ensuring thorough cleaning. Familiarity with each of these parts allows for informed decisions about maintenance or part replacement, keeping your device in optimal condition for longer periods.

By knowing the functions and connections of these key elements, users can quickly identify the source of any malfunctions and address them efficiently. Regular care and a basic understanding of how everything works can prevent larger breakdowns, saving both time and money on repairs.

How to Read the Parts Diagram

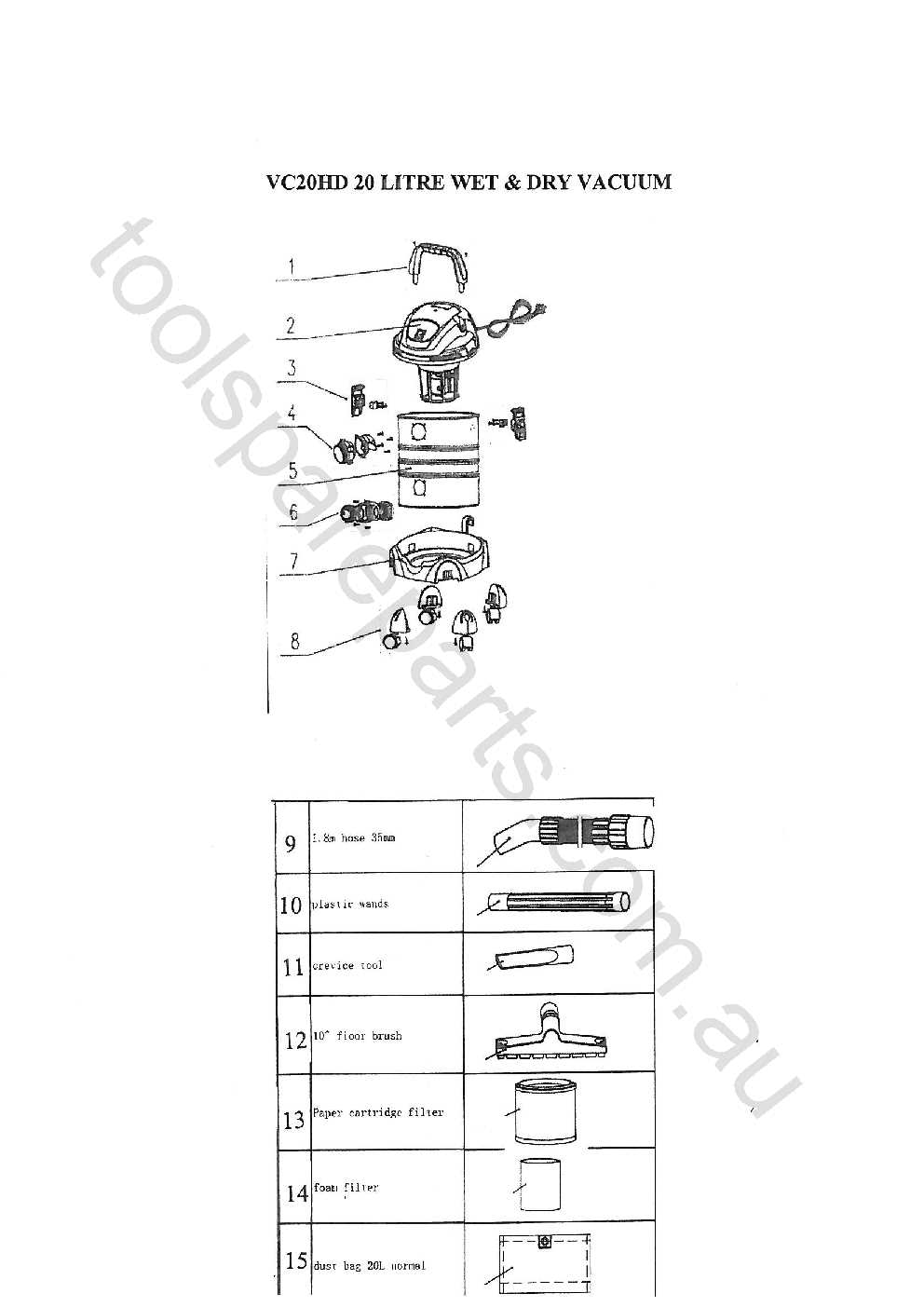

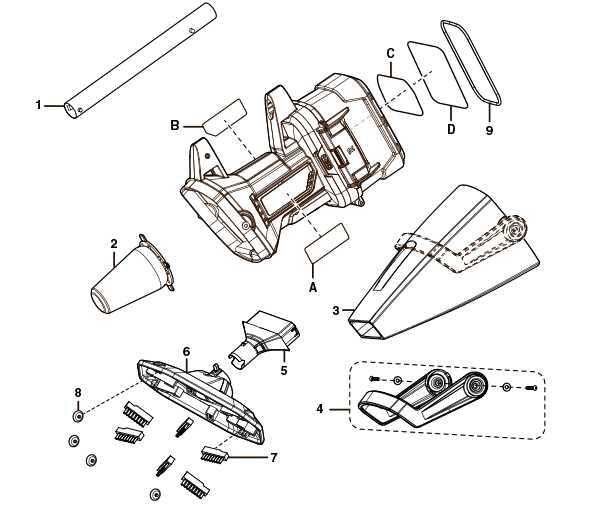

Understanding a schematic or blueprint of your cleaning device is essential for performing accurate repairs or replacing worn-out components. These visual representations offer a clear layout of all the major components, showing their connections and placement within the machine. A well-structured illustration can significantly ease the process of identifying parts and their respective functions.

Identify Key Components and Their Labels

Each element in the schematic is typically labeled with a part number or name, making it easier to find the specific component you need. These labels are crucial for referencing the right replacement or for recognizing when a particular piece might be damaged. Often, the drawing will group similar components together, helping you to understand the overall assembly.

Understanding the Relationships Between Parts

The diagram also highlights how different elements interact with each other, which is vital for troubleshooting issues. By studying the layout and noticing the positioning of parts relative to each other, you can identify potential areas where faults may arise. Understanding these relationships is key to maintaining proper functionality.

Common Issues and Replacement Parts

Like any mechanical device, cleaning equipment can experience wear and tear over time. Identifying common problems early on and knowing what components may need replacing can save time and improve the device’s lifespan. This section covers frequent issues faced by users and the corresponding elements that often require attention or replacement.

Loss of Suction Power

One of the most common issues users encounter is a loss of suction. This can be caused by blockages in the airflow system, worn filters, or malfunctioning motors. Checking the airflow pathway, cleaning filters, and inspecting the motor for any signs of damage can help restore performance. Regular maintenance can prevent these issues from escalating.

Damaged Brushes and Rollers

Another frequent issue involves the brushes or rollers that help agitate dirt and debris. These can become clogged with hair, dirt, or other materials, leading to reduced efficiency. Replacing worn or damaged brushes is essential to maintaining optimal cleaning results. Be sure to check these components periodically to avoid any performance loss.