Proper maintenance of household cleaning equipment relies heavily on knowing the individual components that make up the machine. Understanding how these elements work together ensures efficiency and longevity. The process of identifying and replacing these parts can seem complex, but with the right guidance, it becomes manageable.

Accurate identification of each piece is crucial for effective repairs and upgrades. Whether you are troubleshooting or performing routine maintenance, recognizing the components and their functions allows you to handle issues with ease. By referring to a detailed illustration, you can confidently manage any concerns related to your device’s upkeep.

Having a clear overview of each part’s role helps simplify the maintenance process, minimizing downtime and optimizing performance. Knowing what to look for and how each element interacts with others makes the task less daunting and more straightforward for users of all experience levels.

Understanding Key Components

Maintaining your cleaning equipment requires a solid understanding of its essential components and how they function together. Each part has a specific role that contributes to the overall performance and efficiency of the device. By familiarizing yourself with these elements, you can ensure smoother operation and address potential issues before they become serious problems.

Key components are typically designed to be interchangeable, which allows for easy repairs and upgrades. Knowing which piece does what enables users to diagnose issues quickly, making it possible to replace damaged or worn-out elements without unnecessary delay. This knowledge is essential for both troubleshooting and preventive care.

To fully grasp how these components interact, it’s important to familiarize yourself with their placement and connection points. Whether you’re handling simple maintenance tasks or performing more complex repairs, understanding their structure and function will give you greater control over the upkeep of your equipment.

How to Read a Parts Diagram

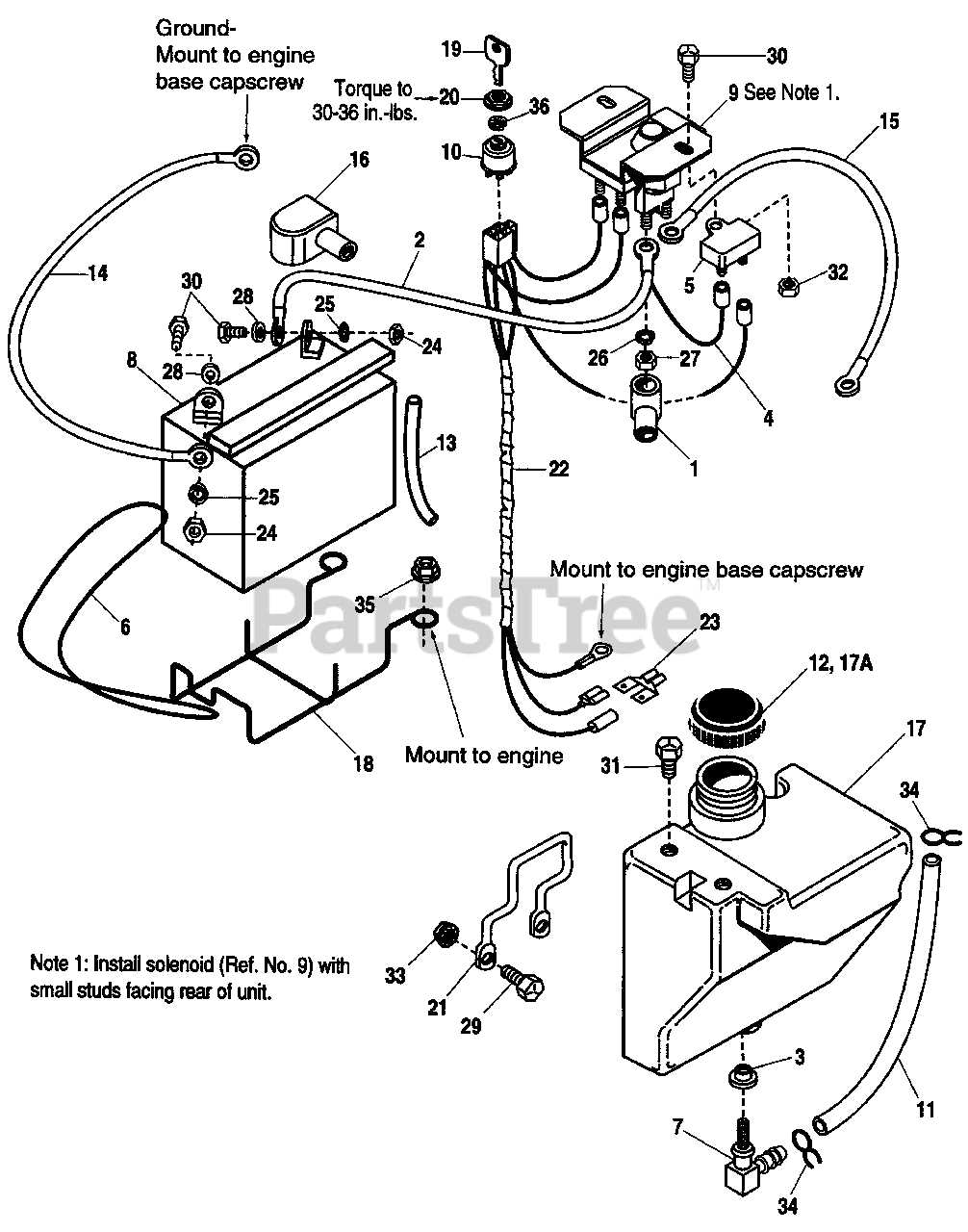

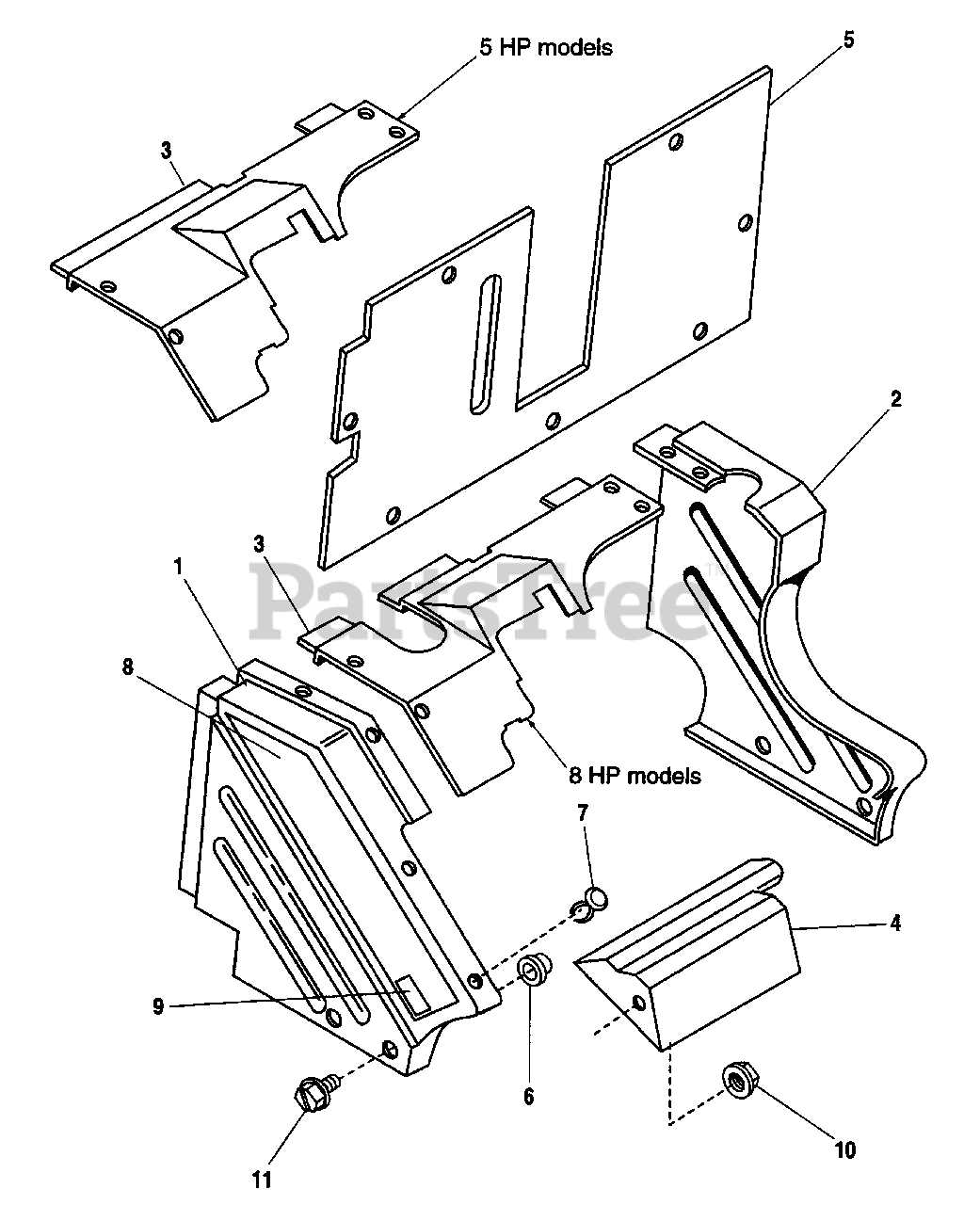

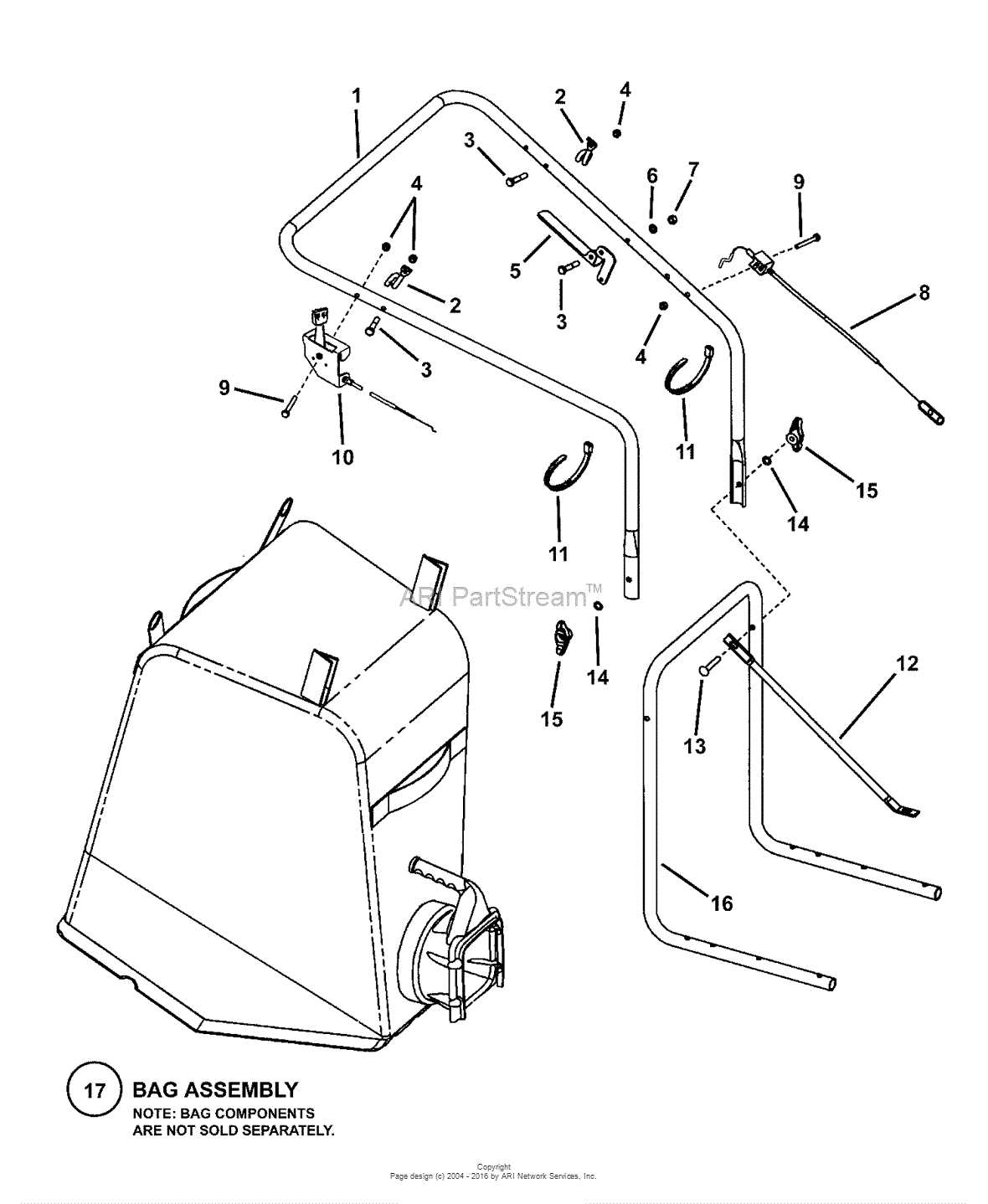

Interpreting visual guides that showcase the various elements of your equipment is a key skill for effective maintenance and repairs. These illustrations provide a clear view of how each component fits into the larger system, helping you identify the exact part that needs attention. By learning how to read these guides properly, you gain the ability to perform more efficient repairs and maintenance.

Identify Key Features

The first step in understanding a visual guide is identifying the key features, such as the labels or numbers that correspond to each component. These labels will usually point out the specific part and offer a reference number, allowing you to cross-check with the product manual or online resources to find more details about the part’s function and specifications.

Understand the Relationships Between Components

Once you are familiar with the individual elements, it’s important to understand how they connect and interact within the system. These connections are often shown through lines or arrows, which indicate the flow or relationship between parts. Recognizing how the elements work together will help you make informed decisions about replacements and repairs, ensuring the device remains functional.

Common Issues and Part Replacements

Over time, regular use can cause certain components of your equipment to wear out or malfunction. Understanding the common issues that arise and knowing which elements need replacement can help you keep the device functioning properly. Addressing problems early prevents larger breakdowns and ensures continued efficiency.

Worn-out or Broken Components

One of the most frequent issues is the wear and tear of key elements. Belts, filters, and brushes are often the first to show signs of damage or degradation. These components work tirelessly during operation, and over time, they can become less effective or break entirely. Replacing these elements as soon as you notice a problem can prevent further damage to the entire system.

Loss of Power or Suction

Another common issue is a noticeable drop in power or suction. This can be caused by clogs, damaged seals, or malfunctioning motors. Inspecting the airflow pathways and checking the functionality of the motor can help you identify the source of the issue. In many cases, replacing a faulty part, like a motor or seal, restores the device to its optimal performance.