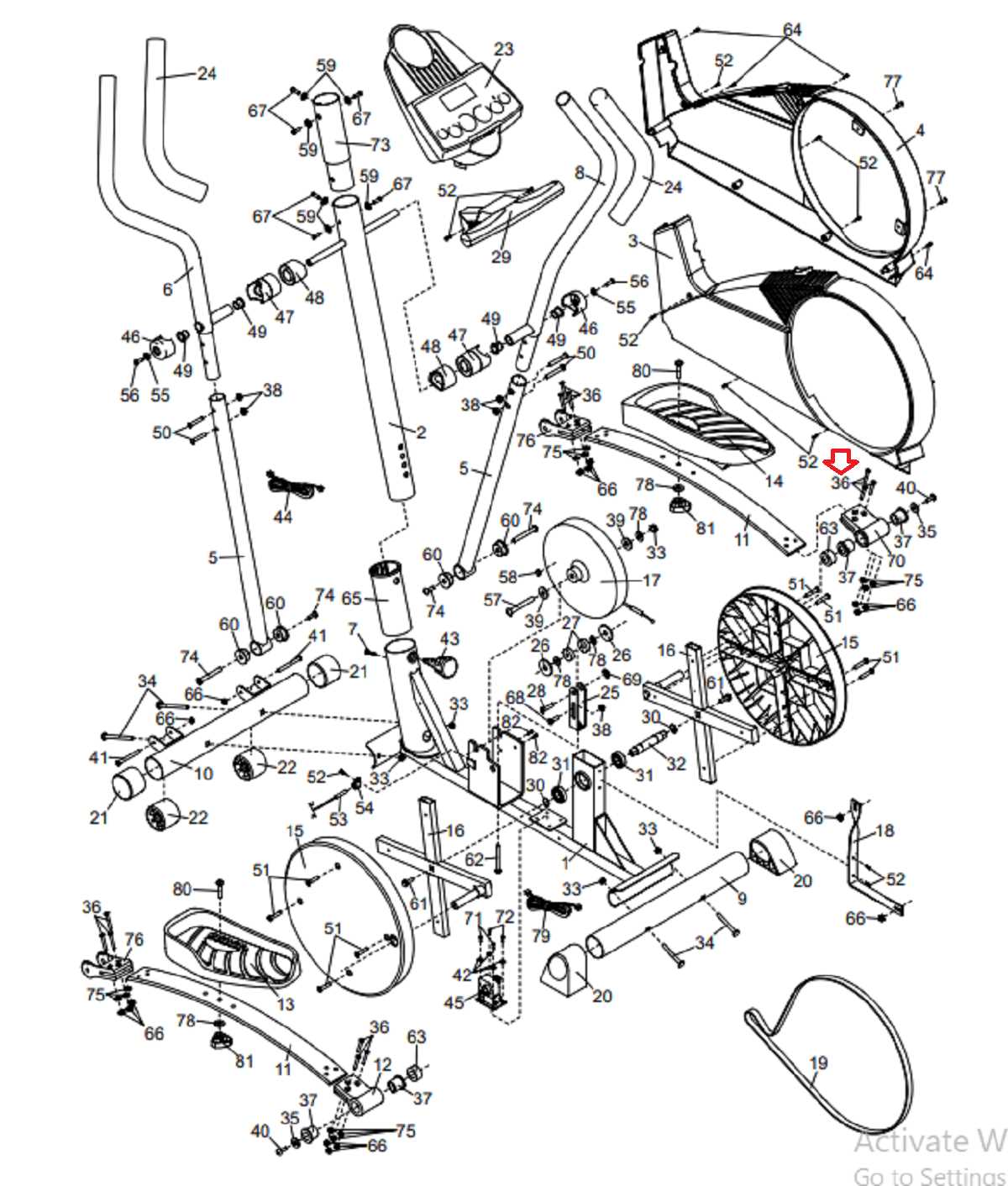

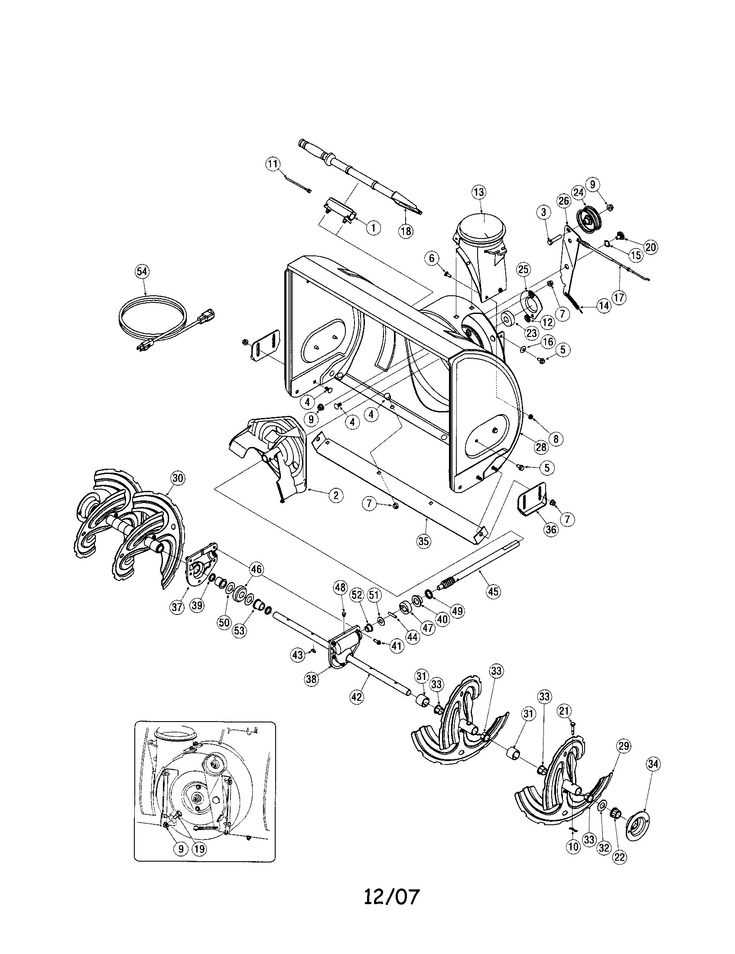

Maintaining outdoor machinery requires a clear understanding of its individual elements. When troubleshooting or performing routine maintenance, knowing where each component fits and how it functions is essential for ensuring long-term efficiency. A detailed map of the machine’s structure helps users identify specific areas for repair or replacement, streamlining the maintenance process.

By familiarizing yourself with the critical components of your equipment, you can easily locate problems and enhance performance. A visual reference that outlines each part’s position and role can save time and reduce confusion during repairs. This guide is designed to offer insight into how different sections interact, making it easier to handle potential issues.

Understanding Snow Clearing Equipment Components

Proper knowledge of how different components of your equipment work together is essential for effective maintenance and troubleshooting. Each element serves a specific purpose, contributing to the overall performance. By recognizing the function and placement of every piece, you can ensure your machinery runs smoothly and handle any issues that arise with greater ease.

Key Mechanical Elements

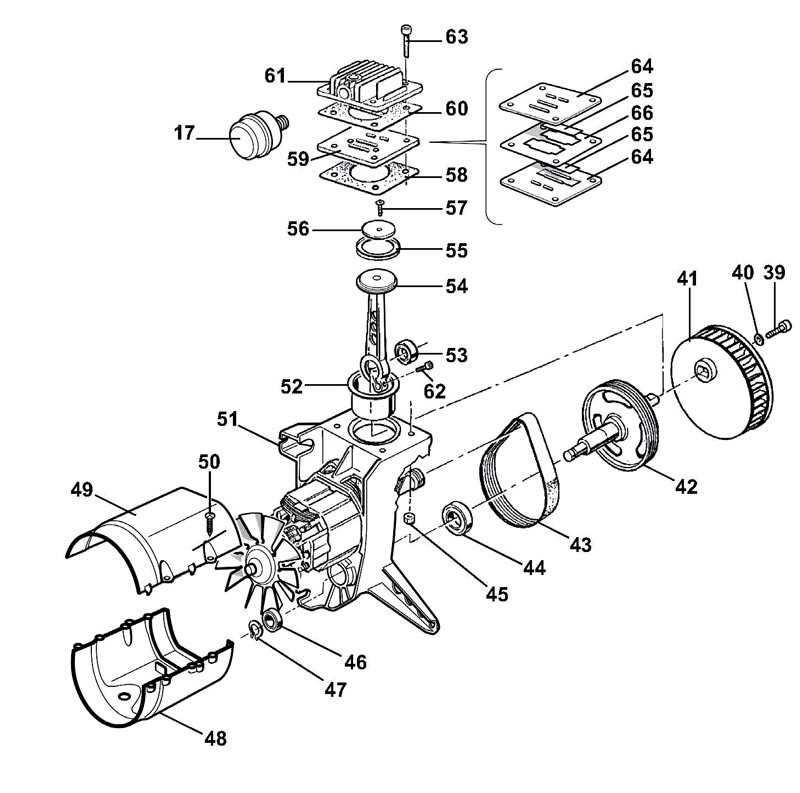

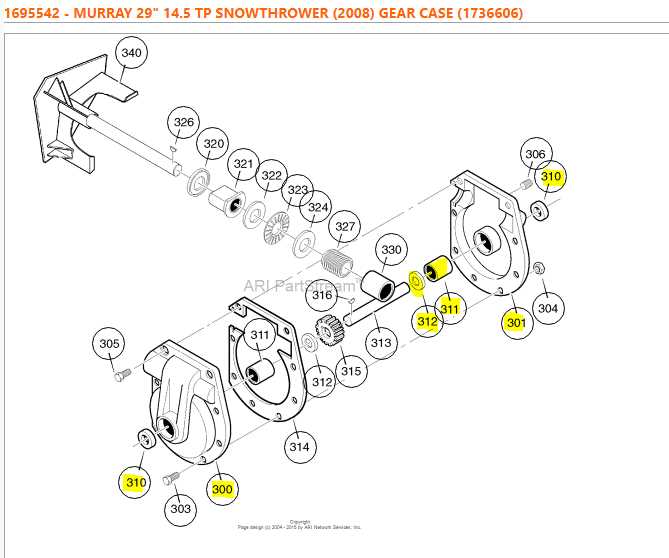

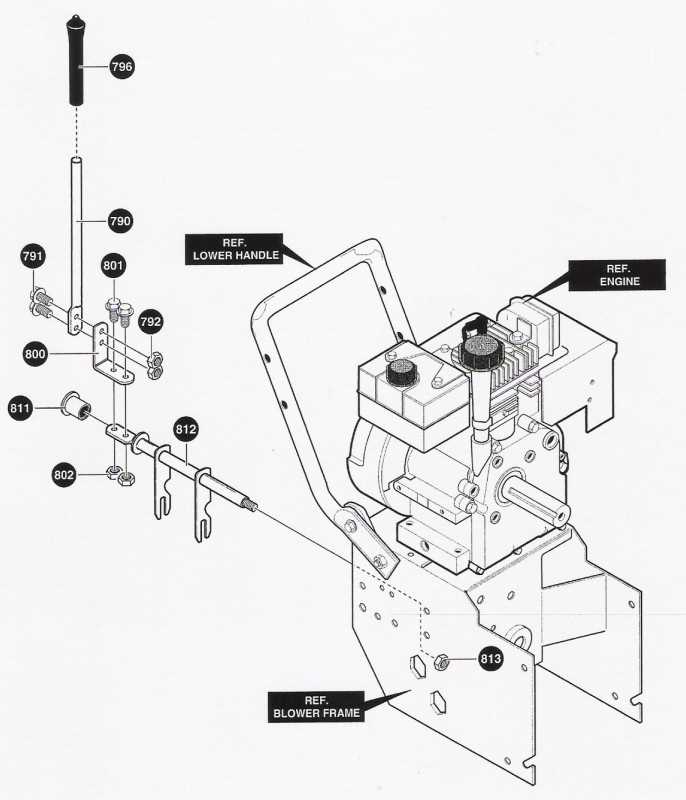

The heart of any outdoor machine lies in its mechanical systems. Understanding how the drive mechanism, auger, and chute interact is critical for efficient operation. These components work in tandem to handle various tasks, such as clearing snow and directing it away from paths. A malfunction in any of these parts can lead to reduced functionality, so familiarity with their roles helps identify potential problems quickly.

Electrical and Control Systems

Alongside mechanical parts, electrical systems play a crucial role in modern equipment. The motor, lights, and ignition systems are vital for starting the machine and ensuring smooth operation. Understanding how to check these systems and troubleshoot any issues will help keep your equipment in optimal working condition. By regularly inspecting electrical connections and ensuring proper functionality, you can prevent unexpected failures during use.

Identifying Key Parts in the Visual Guide

Understanding the different sections of your machine is crucial for efficient operation and troubleshooting. A detailed visual reference helps you pinpoint essential elements quickly, allowing for smoother maintenance and faster problem-solving. By recognizing key components and their functions, you can ensure that the equipment performs at its best throughout the season.

The first step in maintenance is to familiarize yourself with the major components of the system. These include the drive mechanism, auger, and engine parts. Each of these elements plays a specific role in the equipment’s ability to clear paths effectively. Knowing their exact placement and function allows you to easily locate them during routine checks or repairs.

In addition to mechanical components, the control and electrical systems are equally important. The ignition, switch, and motor connections need to be regularly inspected to ensure they are working properly. A thorough understanding of these parts will help identify any electrical failures or control issues that could affect performance.

Maintaining Your Equipment Efficiently

Proper maintenance is essential for extending the lifespan of your machinery and ensuring it works effectively throughout the season. Regular checks and timely repairs can prevent unexpected breakdowns and improve overall performance. By understanding the components and following a routine care schedule, you can keep your equipment running smoothly and avoid costly repairs in the future.

Start by inspecting the major mechanical elements regularly, such as the drive system and the chute. These parts endure a lot of wear and tear, so checking for signs of damage or wear is crucial. Additionally, ensure that the moving parts are lubricated as required to prevent friction and maintain optimal operation.

Don’t forget about the engine and electrical systems, which also require periodic attention. Regularly cleaning the air filters, checking fuel levels, and inspecting wiring connections will help keep your equipment running at peak performance. By staying on top of these routine tasks, you can enjoy hassle-free operation even in harsh weather conditions.