In any farming machinery, understanding the individual elements and their functions is key to achieving optimal performance and longevity. When it comes to complex agricultural tools, having a clear visual representation of each component can be incredibly helpful for users and technicians alike. These illustrations simplify the process of maintenance and troubleshooting, ensuring efficient operations in the field.

By identifying and understanding the role of each piece, operators can better manage their machinery, identify potential issues, and take preventative measures. Whether you’re performing routine maintenance or handling more advanced repairs, knowledge of the structure can significantly reduce downtime and enhance productivity.

Maintenance and care are vital for preserving the functionality of every mechanical system. A detailed overview of individual parts allows users to perform necessary adjustments and replacements with confidence, leading to smoother and more reliable performance.

Understanding the Tye Grain Drill Components

Every agricultural machine is made up of several critical elements, each contributing to its overall functionality and performance. Understanding how these components work together can significantly improve the efficiency of fieldwork and the longevity of the equipment. A clear grasp of each piece’s role is essential for anyone working with complex farming machinery.

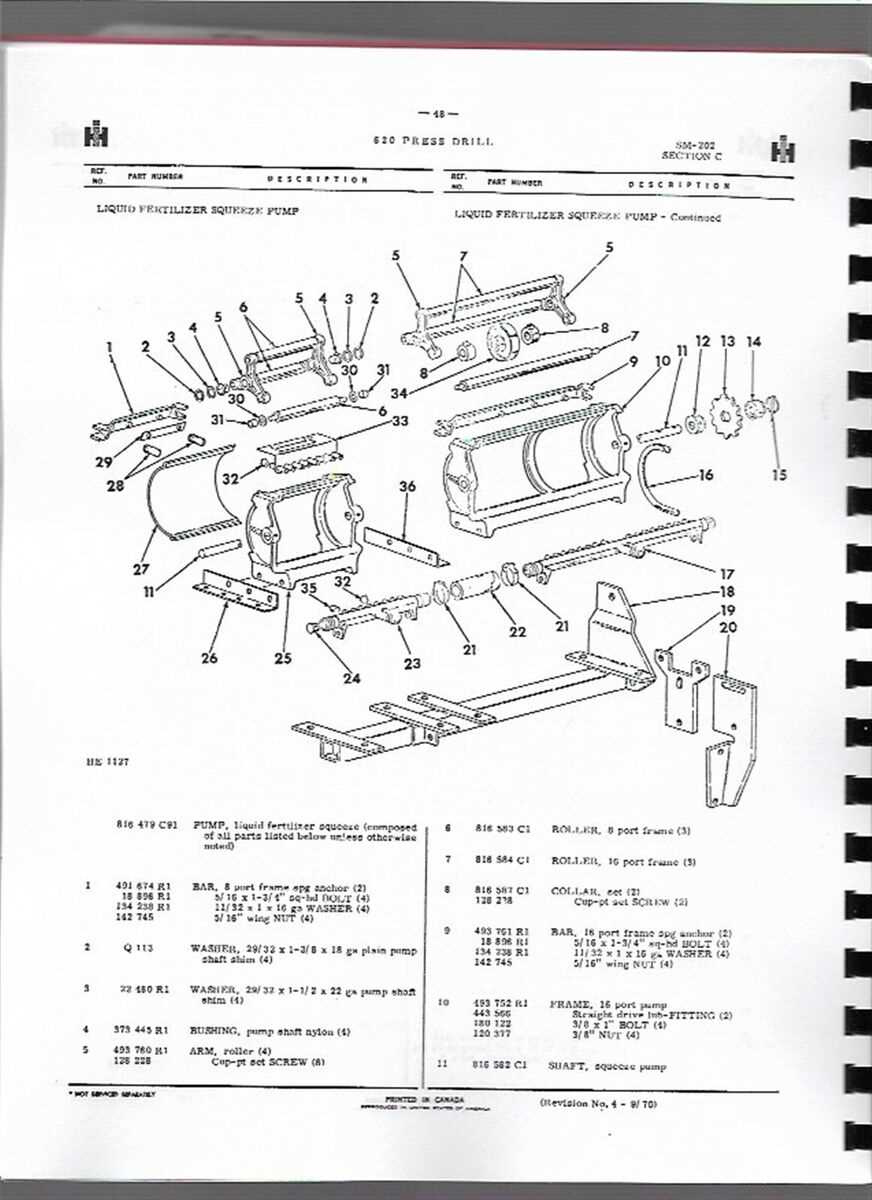

The primary components of such tools include mechanisms responsible for planting, adjusting seed placement, and ensuring even distribution across the land. Each unit has a specific task that complements others, making the system work cohesively. These elements can range from moving parts like gears and belts to static ones like frames and hoppers.

Proper identification of each component allows for more precise maintenance, troubleshooting, and repair procedures. With the right knowledge, technicians and operators can pinpoint malfunctions quickly, minimizing downtime and maximizing output. Regular checks of individual sections are crucial for detecting wear and tear before they lead to significant failures.

Additionally, understanding the connection between all elements helps in making informed decisions when upgrading or replacing equipment. Whether adjusting for field conditions or enhancing the machinery’s performance, knowing each component’s function is invaluable.

Key Parts of Tye Grain Drills Explained

Each agricultural implement consists of several crucial components that contribute to its overall functionality. Understanding how these elements interact ensures that the machine performs at its best while also simplifying maintenance tasks. From the delivery system to the adjusting mechanisms, each piece has a specialized role to play.

The primary units include the mechanism that controls the flow of seeds, ensuring uniform distribution across the field. This system is often coupled with the wheels and rollers that control depth and seed placement. Adjustments to these elements are essential for different soil conditions and crop requirements.

Additionally, the framework of the machine provides structural integrity, ensuring that all components are aligned correctly and able to withstand the forces exerted during operation. This part supports everything from the seed boxes to the cutting systems, which work together to prepare the soil for planting.

Other notable parts include the gears and belts that drive movement, helping the machine maintain consistent speed and motion. Regular inspection of these parts is crucial for ensuring smooth operations and preventing breakdowns during critical farming periods.

How to Maintain Tye Grain Drill Parts

Regular maintenance of agricultural equipment is vital for ensuring long-term functionality and reducing unexpected downtime. Taking care of individual components prevents wear and tear and ensures the machine operates smoothly throughout the growing season. By focusing on key areas of maintenance, farmers can keep their equipment in peak condition.

Routine Inspections and Lubrication

One of the most important tasks in maintaining farming machinery is regular inspection. Checking for signs of wear, loose parts, or accumulated dirt can help prevent costly repairs later on. Ensuring that moving parts are properly lubricated is crucial for reducing friction and preventing unnecessary damage.

Adjusting and Replacing Worn Components

Over time, certain elements may require adjustments or replacements. Parts that handle movement, like gears and belts, are subject to wear and need periodic examination. If any parts are found to be too damaged, they should be replaced immediately to avoid further damage to the system.

By staying on top of these tasks, operators can extend the lifespan of their equipment, minimize breakdowns, and maintain consistent performance in the field.