Understanding the essential elements of a marine propulsion system is key to ensuring both performance and reliability. These systems consist of numerous interconnected components that work together to propel the vessel. Identifying these key elements helps boat owners and technicians maintain and repair the machinery effectively.

Essential Elements of the Drive Mechanism

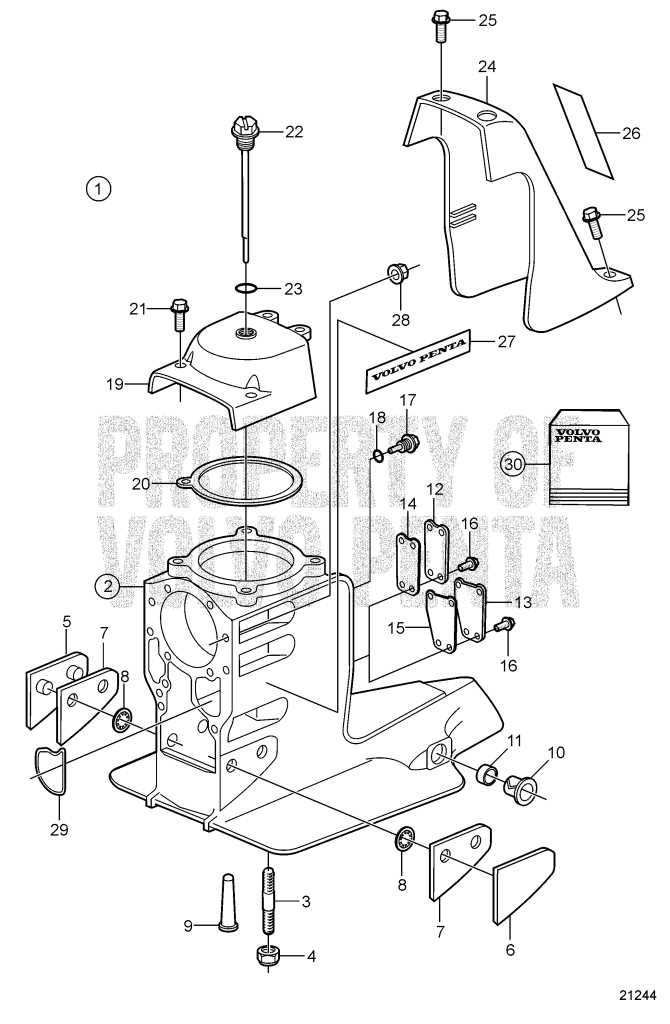

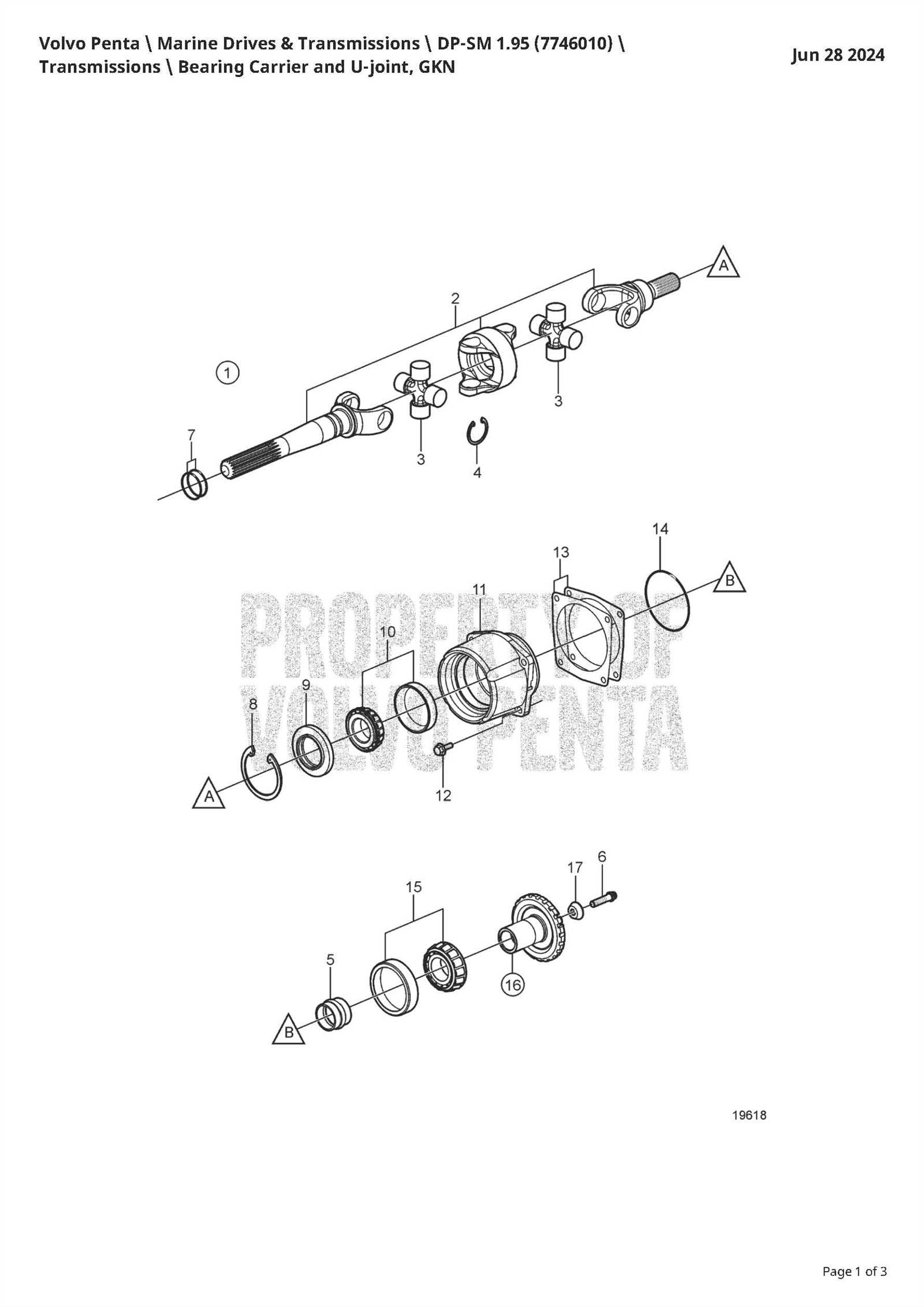

Each vessel’s drive mechanism consists of a series of parts designed to transmit power from the engine to the propellers. These components include gears, shafts, seals, and other vital elements, each playing a crucial role in the efficient functioning of the system.

Main Components

- Gearbox – Transmits engine power to the propeller shaft.

- Shafts – Transfer rotational power from the gearbox to the propeller.

- Seals – Prevent water and other contaminants from entering the system.

- Propeller – Converts the engine’s power into forward motion for the boat.

Maintaining Your Drive System

Proper maintenance is essential for extending the lifespan of your system. Regular checks for wear and tear, fluid levels, and component alignment are key to preventing issues before they arise.

Maintenance Tips

- Inspect seals regularly to avoid water ingress that can cause rust or corrosion.

- Lubricate gears and moving parts to ensure smooth operation.

- Monitor fluid levels to maintain the performance and prevent overheating.

Common Issues to Watch For

Over time, components can become worn or damaged, leading to inefficiencies or even breakdowns. It’s important to address the following signs promptly:

- Unusual noises from the system could indicate gear or bearing damage.

- Leaking fluids may suggest faulty seals or gaskets.

- Vibrations could point to misalignment or damage to the shaft or propeller.

Understanding Drive Mechanism Components and Their Maintenance

Proper functioning of a vessel’s propulsion system relies on the coordination of various mechanical elements. These components, essential for converting engine power into movement, require regular inspection and maintenance. Understanding their role and how to keep them in optimal condition ensures smooth performance and avoids costly repairs.

Key components of the propulsion assembly include the transmission, gears, shafts, and seals. Each of these elements plays a unique role in power transmission and must be kept in good working order. Knowing their functions and how they interconnect can help identify potential issues early, preventing more serious damage.

Maintenance is crucial for extending the lifespan of these systems. Regular lubrication, fluid checks, and timely part replacement are essential for maintaining peak performance. Keeping a close eye on wear and tear, particularly on high-stress areas like seals and gears, is key to avoiding unexpected breakdowns.

To ensure longevity, it’s important to address any minor issues before they turn into major problems. This includes monitoring fluid levels, checking for leaks, and verifying that all components are properly aligned. Taking these steps can significantly reduce the need for costly repairs and help maintain the overall health of the system.

Common issues with these mechanical systems often stem from poor maintenance practices or natural wear. Leaking seals, noisy gears, and vibrations during operation can signal problems that need immediate attention. Identifying these signs early allows for corrective actions before more serious failures occur.