In any modern vehicle, the system responsible for transferring power from the engine to the wheels consists of several interconnected elements. These components play a critical role in ensuring smooth performance and efficiency, making it essential to understand their functions and interactions. Whether you’re a car enthusiast or a professional mechanic, knowing the structure of this assembly can help diagnose issues and improve maintenance strategies.

The central mechanism that facilitates power distribution often involves a complex setup of gears and shafts. Each part contributes to the system’s overall operation, ensuring optimal traction and stability. A thorough understanding of this structure is invaluable for anyone involved in vehicle repair or maintenance.

In this article, we will explore how the individual elements of this system work together to provide smooth driving experiences, the common problems that can occur, and how to identify potential malfunctions based on visual or mechanical cues. The goal is to provide a comprehensive overview that enhances your knowledge and ability to manage the vehicle’s core functions effectively.

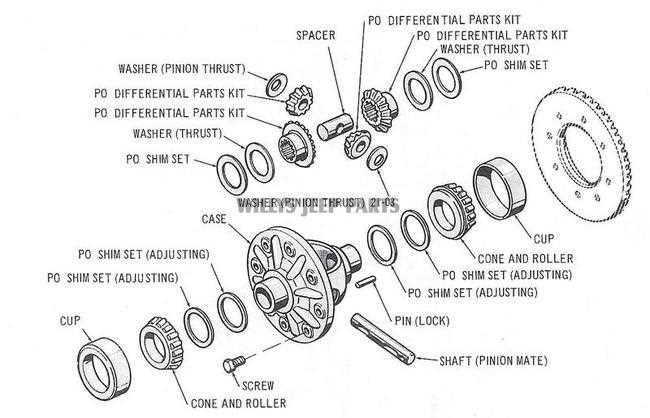

Key Components of Rear Differential

The system responsible for distributing power to the wheels relies on several key elements that ensure efficient operation. Each of these components has a specific role, allowing the vehicle to maintain smooth performance, especially when turning or navigating various terrains. Understanding how these elements work together can help identify potential issues and guide proper maintenance.

Power Distribution Shaft

This component transmits rotational force from the engine to the wheels, enabling motion. It acts as the central conduit for energy transfer within the assembly, ensuring the correct distribution to each wheel for optimal traction. The power distribution shaft is critical for ensuring that both wheels rotate in sync, especially under load.

Gearset

The gearset is responsible for adjusting the torque and rotational speed between the input and output shafts. By using different gear ratios, it adapts to various driving conditions, allowing the vehicle to maintain speed and control across different surfaces. This mechanism is key in achieving smooth transitions during acceleration and deceleration, as well as when navigating tight turns.

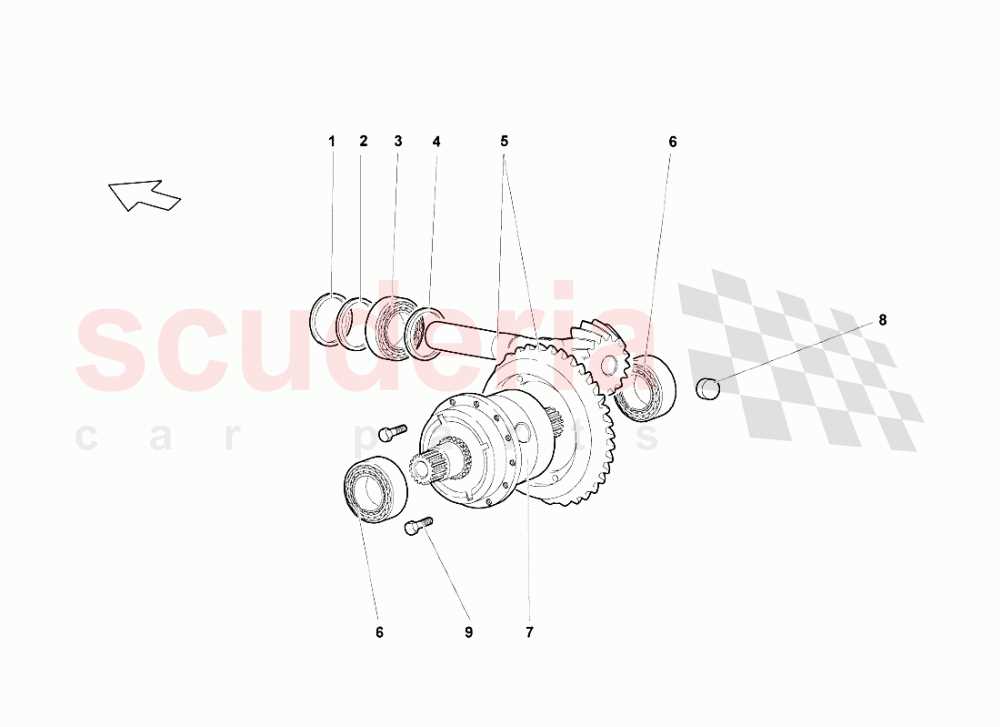

How Rear Differential Works in Vehicles

The system designed to manage power distribution to the wheels plays a crucial role in how a vehicle handles and moves. By allowing the wheels to rotate at different speeds, especially when turning, it ensures smooth driving and enhances maneuverability. This capability is essential for maintaining control and traction, particularly when navigating curves or uneven surfaces.

The process begins when the engine generates power, which is then transmitted through the drivetrain to this central system. The gears within this mechanism adjust the speed and torque, enabling the wheels to move at different rates. This adaptation allows one wheel to rotate faster than the other without causing strain on the vehicle, particularly during turns, where the inner wheel travels a shorter distance than the outer wheel.

Overall, the operation of this system is integral to the vehicle’s ability to move efficiently while providing stability and control, especially in challenging driving conditions. Understanding how it functions helps to appreciate its importance in ensuring a smooth and safe driving experience.

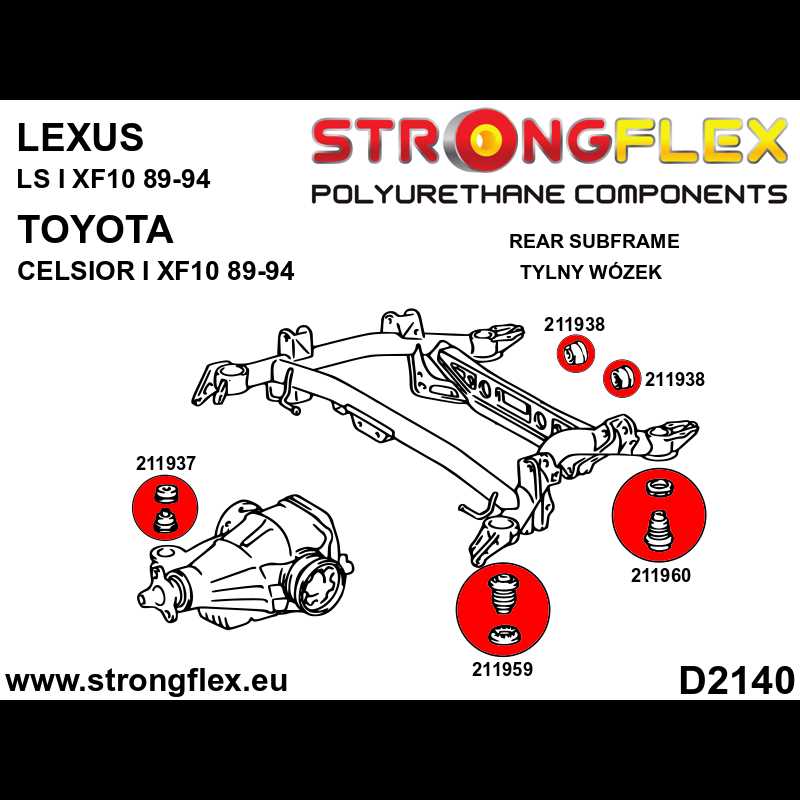

Common Issues with Rear Differential Parts

Like any complex mechanical system, the components responsible for distributing power to the wheels can experience wear and tear over time. Issues can arise due to a variety of factors, including poor maintenance, excessive heat, or lack of proper lubrication. Identifying these problems early can help prevent more severe damage and improve the longevity of the vehicle.

One of the most common issues is insufficient lubrication, which can lead to increased friction and overheating of the internal gears. This problem can cause the components to wear out faster and result in noisy operation or even complete failure. Regular checks and timely oil changes are essential to avoid this scenario.

Gear wear is another frequent issue. Over time, the constant engagement of gears can cause them to wear down, leading to slipping, grinding noises, or a decrease in performance. If left unaddressed, worn gears can lead to further damage, such as broken teeth or system failure. Regular inspections can help catch this issue early, allowing for the replacement of damaged gears before they affect the entire system.

Finally, leaks from the housing can also be problematic, leading to a loss of fluid and poor functioning of the mechanism. Leaks can occur due to damage to seals or gaskets, and without prompt repairs, the system may run dry and suffer damage. Ensuring the seals are intact and checking fluid levels regularly can prevent this issue.