Maintaining a power tool requires an in-depth understanding of its internal components. Whether you’re performing routine maintenance or addressing a malfunction, knowing how each part interacts with the others can significantly improve your repair experience. This guide will help you visualize the essential elements that make up the tool and understand their function in a clear, straightforward manner.

Every machine is made up of various elements working together in harmony. From the engine to the minor accessories, each component has a crucial role in the overall performance of the equipment. By understanding how these pieces are connected, you can troubleshoot problems more efficiently and carry out repairs with greater precision.

Proper knowledge of the assembly will not only assist in fixing issues but also ensure you get the most out of your tool, enhancing its lifespan and functionality. Whether you’re a beginner or an experienced user, familiarizing yourself with the system will help you maintain it with confidence and ease.

Understanding the MS250 Chainsaw Components

In any mechanical tool, each element serves a vital function, contributing to its overall performance. A thorough understanding of these components is essential for anyone looking to maintain or repair their equipment. Knowing the role of each part and how they work together allows users to troubleshoot issues more effectively and perform precise repairs when needed.

Key Functional Elements

At the core of the tool lies the engine, which powers all functions. It works in tandem with the fuel system, ignition, and exhaust components to ensure smooth operation. Additionally, mechanical elements such as the clutch and drive mechanism facilitate the transfer of energy, ensuring that the tool remains efficient during use. Each of these components is interconnected, creating a system that relies on precision and functionality.

Minor Components and Accessories

Though smaller, other components like the air filter, spark plug, and lubrication system play a crucial role in keeping the tool running efficiently. These parts, though often overlooked, prevent damage to the major parts by ensuring proper airflow, spark, and fluid distribution. Regular attention to these details helps preserve the longevity of the machine and prevent costly repairs.

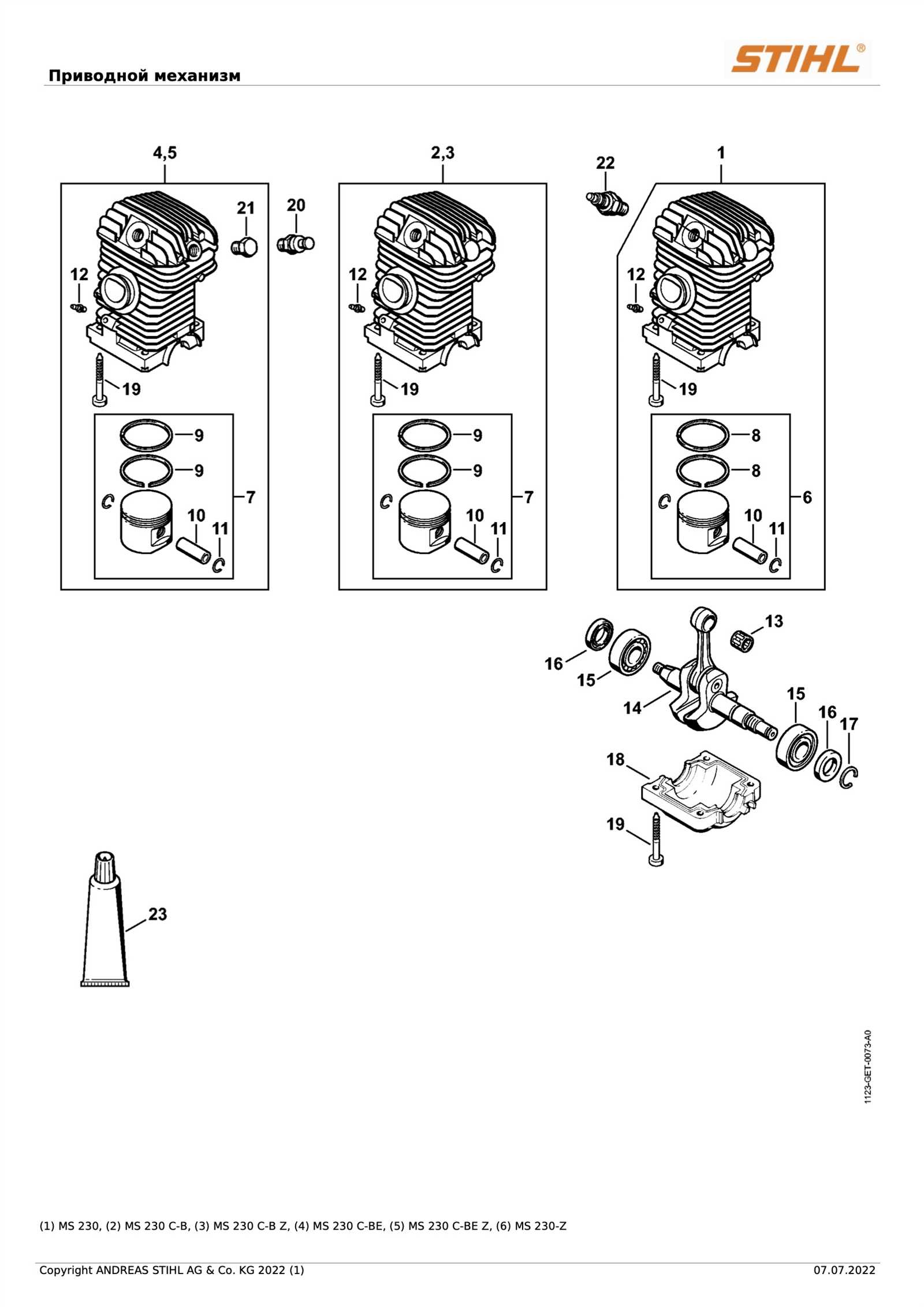

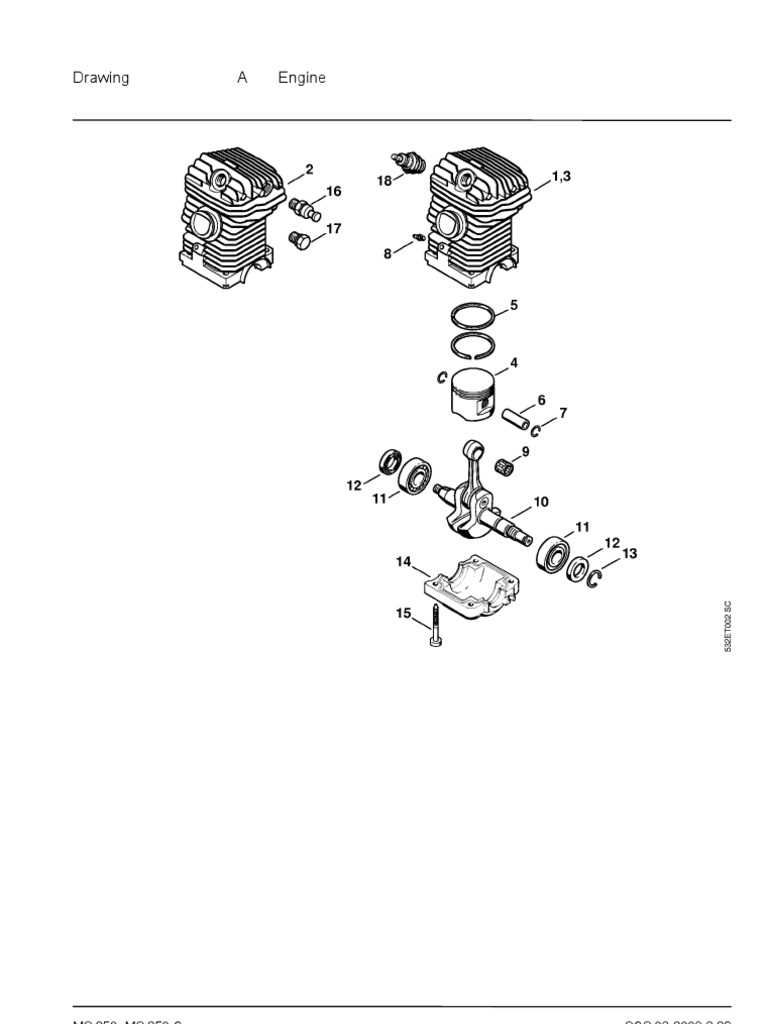

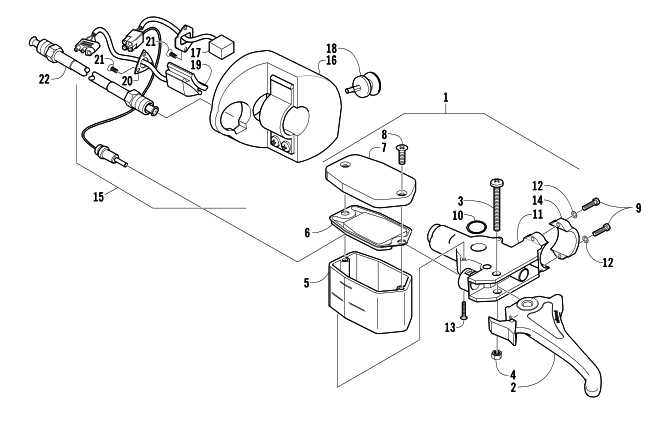

How to Read the MS250 Parts Diagram

Understanding how to interpret a schematic representation of your equipment can significantly improve your ability to maintain and repair it. These visual guides provide a clear breakdown of the tool’s components and how they fit together. By following the illustration and referring to labels and numbers, you can easily identify each part and understand its function within the system.

Identifying Key Symbols and Labels

Each diagram uses specific symbols and numbering systems to represent different components. These symbols are standardized, allowing you to easily spot important parts such as the engine, drive system, and safety features. Labels next to the components often include part numbers, which help you locate the exact replacement pieces when needed.

Following the Assembly Flow

Once you familiarize yourself with the symbols and labels, it’s important to follow the flow of assembly as shown in the diagram. The parts are typically displayed in the order they fit together. Understanding this sequence ensures you can properly disassemble or reassemble the equipment, making repairs much more straightforward.

Common Issues and Replacements for MS250

Like any mechanical device, equipment can experience wear and tear over time. Understanding the common issues that arise with these tools and knowing which components need replacement is crucial for efficient operation. Identifying the problem early and replacing the faulty parts ensures that the tool continues to perform at its best, preventing costly damage in the future.

Engine and Ignition Problems

One of the most common issues is related to the engine or ignition system. If the tool is having trouble starting or running smoothly, the spark plug or the fuel filter might be clogged. Replacing the spark plug and cleaning or replacing the fuel filter can restore the engine’s performance. Additionally, the ignition coil may need to be checked for proper function, as a malfunctioning coil can prevent the engine from starting at all.

Wear on the Drive System

Another common problem occurs within the drive system. Over time, parts like the clutch or drive sprocket can wear down, affecting power transmission. If you notice decreased performance or difficulty in operation, these components might need replacement. Regularly inspecting and replacing worn-out drive components will ensure smoother operation and prevent further damage to other elements of the system.