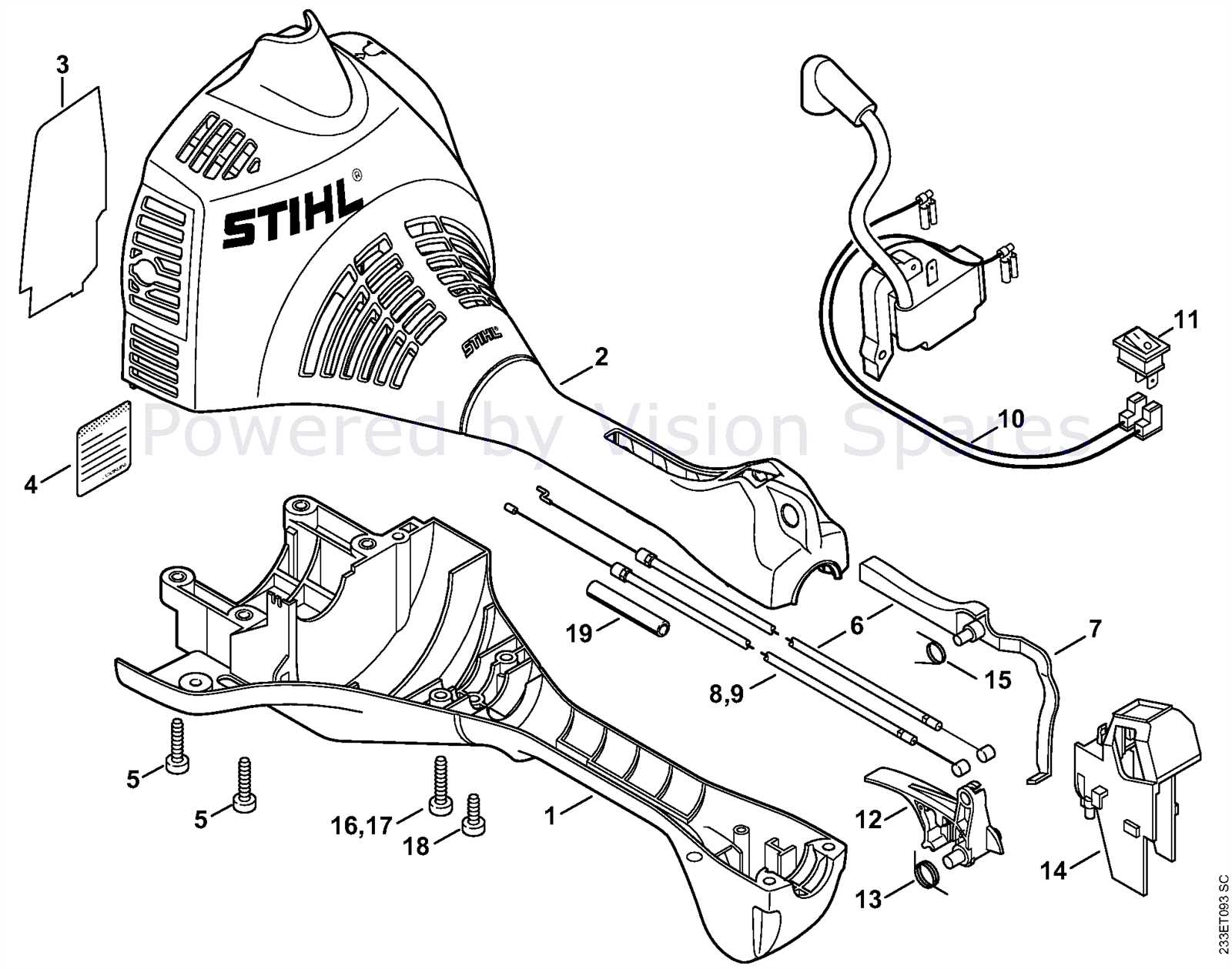

When maintaining or repairing your chainsaw, having access to clear and detailed technical resources is essential. Visual aids, such as exploded views of internal components, help users understand how various parts fit together and function. These resources serve as a valuable tool for both seasoned professionals and DIY enthusiasts.

One of the most useful materials for chainsaw maintenance is a detailed visual breakdown that showcases every individual piece and its relation to others. With such a reference, you can easily identify specific components, order replacements, and assemble the machine accurately. Having this reference at hand ensures a smoother repair process, reducing the chances of errors and downtime.

In addition to simplifying repairs, these resources provide crucial insights into proper maintenance routines. Regular upkeep is key to extending the lifespan of your chainsaw, and understanding the structure and function of each component is the first step toward effective care. Access to high-quality reference materials makes this process easier and more efficient, ensuring that you get the most out of your equipment.

How to Download Stihl 009l Parts Diagram

Accessing detailed visual guides for your chainsaw is an essential step in ensuring proper maintenance and efficient repairs. These visual resources, often provided as downloadable files, offer a clear view of your machine’s inner workings and components. With a few simple steps, you can easily obtain these helpful references, making your repair tasks more straightforward and manageable.

To begin, start by visiting trusted websites that specialize in providing technical manuals and schematics for outdoor equipment. Many manufacturers and third-party platforms offer free access to these resources. Look for the specific model or tool you need and ensure that the file you’re downloading is compatible with your needs. Often, these files are available in common formats like JPG or ZIP, making them easy to open and use on various devices.

Once you’ve located the right resource, simply click on the download link. The file will typically be saved to your computer or mobile device. After the download is complete, you can open the file using any standard viewer or print it out for easy reference during repairs. Having this guide available whenever you need it ensures you can tackle maintenance tasks with confidence and precision.

Understanding the Stihl 009l Parts Breakdown

When it comes to equipment maintenance, having a clear understanding of how each component interacts within the machine is crucial. A comprehensive breakdown reveals the internal structure, allowing you to identify each individual part and its function. This knowledge is essential for performing repairs, replacing damaged components, and ensuring optimal performance over time.

Identifying Key Components

Each tool consists of a variety of small and large components, each playing a specific role in the operation of the machine. Recognizing key elements such as the fuel system, ignition system, and mechanical assembly is vital for both troubleshooting and performing repairs. By understanding their placement and how they interact, you can pinpoint potential issues with greater accuracy.

How to Interpret the Breakdown

Visual representations of the machine’s internals often include numbered references or labels to make identification easier. Carefully studying these breakdowns helps you to understand not only the names and positions of each part but also how to remove, replace, or maintain them. Knowing the assembly sequence and the tools required for specific tasks ensures that you don’t miss crucial steps during repairs.

Benefits of Using a Parts Diagram for Maintenance

Utilizing a visual guide that outlines the internal components of your tool offers numerous advantages when it comes to maintenance. These resources provide clarity on how each element fits into the overall system, making the repair process more organized and efficient. They help identify which parts require attention, making troubleshooting and replacements easier.

One of the key benefits is accuracy. By following a detailed visual reference, you minimize the risk of errors during disassembly or reassembly. This ensures that all components are correctly positioned, reducing the likelihood of further damage or improper operation. Additionally, these guides can save time by clearly showing the steps involved in each procedure.

Another advantage is the ability to maintain regular upkeep. With easy access to a breakdown of the machine, you can schedule maintenance tasks at appropriate intervals, preventing wear and tear. This proactive approach helps extend the lifespan of your equipment, ensuring that it remains in top working condition for longer periods.