Maintaining a well-functioning outdoor tool requires knowledge of its individual parts and how they work together. Whether you are a professional or a DIY enthusiast, having a clear understanding of your trimmer’s structure can save time and money on repairs. Proper care and attention to each element ensure optimal performance and longevity.

When it comes to keeping your equipment in top shape, knowing where each piece fits and how to replace damaged or worn components is crucial. Understanding the layout of your tool and identifying areas prone to wear can make maintenance a simpler task, ensuring efficient use for years to come.

Regular maintenance is key to extending the lifespan of any machine. By following a clear guide and being familiar with the specific parts, you can confidently address any issues that arise and prevent costly repairs. With the right knowledge, you’ll be able to manage your equipment’s upkeep effectively.

Understanding FS 40 C Components

Each outdoor tool consists of multiple interconnected elements that work in harmony to ensure smooth operation. Recognizing how these components interact and their specific functions can significantly enhance your ability to maintain the equipment effectively. From the engine to the cutting mechanism, understanding the role of each section is essential for both repairs and routine upkeep.

By becoming familiar with the different segments of your tool, you can quickly diagnose potential issues and perform the necessary adjustments. Knowing the function of each part allows for targeted maintenance, reducing downtime and ensuring continued efficiency.

Key Functional Elements

The engine is the heart of the machine, driving all other components. The powerhead, fuel system, and ignition are critical for reliable operation. Other essential sections, such as the handle and control mechanisms, allow for user comfort and safety while operating the equipment. Regular inspection of these areas helps to prevent malfunction and prolongs the overall life of the tool.

Maintenance and Care

Routine checks of the mechanical parts, fuel lines, and safety features are crucial for keeping everything in working order. By understanding how each section contributes to the overall performance, you can take a proactive approach to maintenance. Regular cleaning, lubrication, and part replacement as needed will ensure the tool operates smoothly and efficiently, reducing the likelihood of costly repairs.

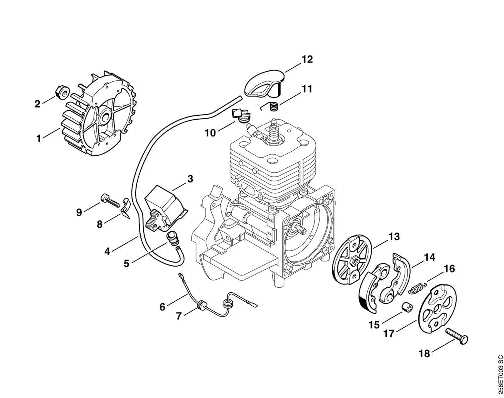

How to Read the Parts Diagram

Understanding how to interpret visual guides for your tool is essential for effective maintenance and repairs. These illustrations provide a clear representation of the various components and their placement, allowing you to easily identify each piece and its function. Knowing how to read these guides can help you navigate complex repairs, ensuring you have all the necessary parts to get the job done right.

Key Symbols and Labels

Most visual guides use specific symbols and numbers to represent different sections and parts of the tool. These symbols are often paired with labels to give you detailed information about each component. Here’s what to look for:

- Numbers and Labels: Each element is typically numbered for easy identification, and the accompanying labels provide names or functions.

- Lines and Connections: Lines show how parts are connected or interact with one another. Dotted or solid lines may indicate different types of connections.

- Sections: Parts are often grouped into sections to make understanding the overall structure simpler.

Following the Guide for Repairs

Once you are familiar with the key symbols and labels, you can use the guide to navigate through any repair process. The visual representation helps you to:

- Identify damaged or worn-out elements that need replacing.

- Understand how to disassemble and reassemble your tool with ease.

- Verify that all parts are in place after maintenance or replacement.

By learning to read and interpret these guides, you will be able to perform maintenance tasks efficiently and with confidence.

Essential Components for FS 40 C

Every outdoor tool is built around a core set of functional elements that allow it to perform its tasks effectively. These critical components work together to ensure that the tool operates smoothly, providing the necessary power and control for various tasks. Understanding these essentials will help you keep your equipment running efficiently and make informed decisions about maintenance and repairs.

Power Mechanism and Control

The engine and fuel system form the backbone of the equipment, converting fuel into the power needed to drive the cutting action. Additionally, the control handles and throttle systems enable users to maintain comfort and precision during operation. Regular inspection of these components ensures consistent performance and prevents potential issues.

Cutting Mechanism and Safety Features

Another crucial aspect is the cutting mechanism, which typically includes a blade or string system designed to handle heavy-duty tasks. The safety features such as guards and handles are essential for user protection and should always be kept in good condition. Ensuring these elements are properly maintained prevents accidents and guarantees efficient performance during use.

Identify and Replace Damaged Parts

Properly identifying and replacing malfunctioning components is key to keeping your outdoor tool functioning at its best. When a part becomes worn or damaged, it can affect the overall performance and safety of the equipment. By knowing how to recognize these issues early, you can take swift action to replace the faulty elements and restore your tool’s efficiency.

Signs of Wear and Tear

Common signs of damage include unusual noises, decreased power, or physical damage such as cracks or tears. Regularly inspecting your tool helps to catch issues before they escalate, making repairs easier and less costly.

Replacing Malfunctioning Components

Once a damaged part is identified, it’s important to select the correct replacement to ensure compatibility and maintain the performance of your tool. The following table outlines some common components and the signs that indicate they may need replacing:

| Component | Signs of Damage | Replacement Action |

|---|---|---|

| Fuel Line | Leaking fuel, cracks | Replace the fuel line with a new one to prevent leakage and ensure safe operation. |

| Cutting Head | Visible wear, cracks | Install a new cutting head or string to maintain optimal cutting performance. |

| Throttle Trigger | Sticking or non-responsiveness | Replace the throttle trigger to restore responsive control of the tool. |

Replacing these damaged components not only restores your equipment to full functionality but also extends its lifespan, ensuring reliable performance for every task.

Maintaining Your FS 40 C

Regular maintenance is essential for ensuring that your outdoor tool continues to function efficiently over time. By performing routine checks and addressing minor issues before they become major problems, you can extend the life of your equipment and keep it performing at its best. Proper care helps maintain optimal performance, reduces downtime, and avoids costly repairs.

Key maintenance tasks include cleaning, lubricating, and replacing worn or damaged components. It’s also important to check the fuel system, cutting mechanism, and safety features regularly. Following the manufacturer’s guidelines for maintenance ensures that each part is cared for properly, preventing malfunctions and ensuring reliable operation.