When it comes to maintaining and repairing your chainsaw, knowing the key elements and how they work together is essential. Proper knowledge allows for quick and effective troubleshooting, ensuring your tool runs efficiently for a long time.

By understanding the layout of the tool’s internal systems, users can easily identify any issues that might arise. This knowledge also helps in sourcing the right replacement parts when necessary, streamlining the repair process.

Whether you’re performing regular maintenance or need to fix a specific issue, being familiar with the components will save you time and effort. With the correct guidance, you’ll be able to identify and replace any worn-out elements quickly, keeping your tool in top working condition.

Understanding the Chainsaw Components

To ensure the longevity and proper functioning of any chainsaw, it’s essential to familiarize yourself with its internal structure. Each individual component plays a crucial role in the overall operation of the tool, from its ignition system to its cutting mechanism. Recognizing these elements and understanding their interactions helps in troubleshooting, maintenance, and repairs.

Key Elements of the Internal Mechanism

The internal system includes critical parts like the engine, fuel system, and exhaust, all of which contribute to the tool’s efficiency. The engine serves as the heart of the machine, while the fuel system ensures proper combustion, enabling the tool to function smoothly. The exhaust system, in turn, helps expel gases safely, contributing to better performance and safety.

Identifying Wear and Tear

Over time, certain components may wear down due to regular use, which can affect the overall performance. Identifying these parts early can prevent more severe issues down the line. Whether it’s the carburetor, the air filter, or the chain, understanding how each component functions allows for easy identification of worn-out parts that need replacement or repair.

How to Read the Chainsaw Blueprint

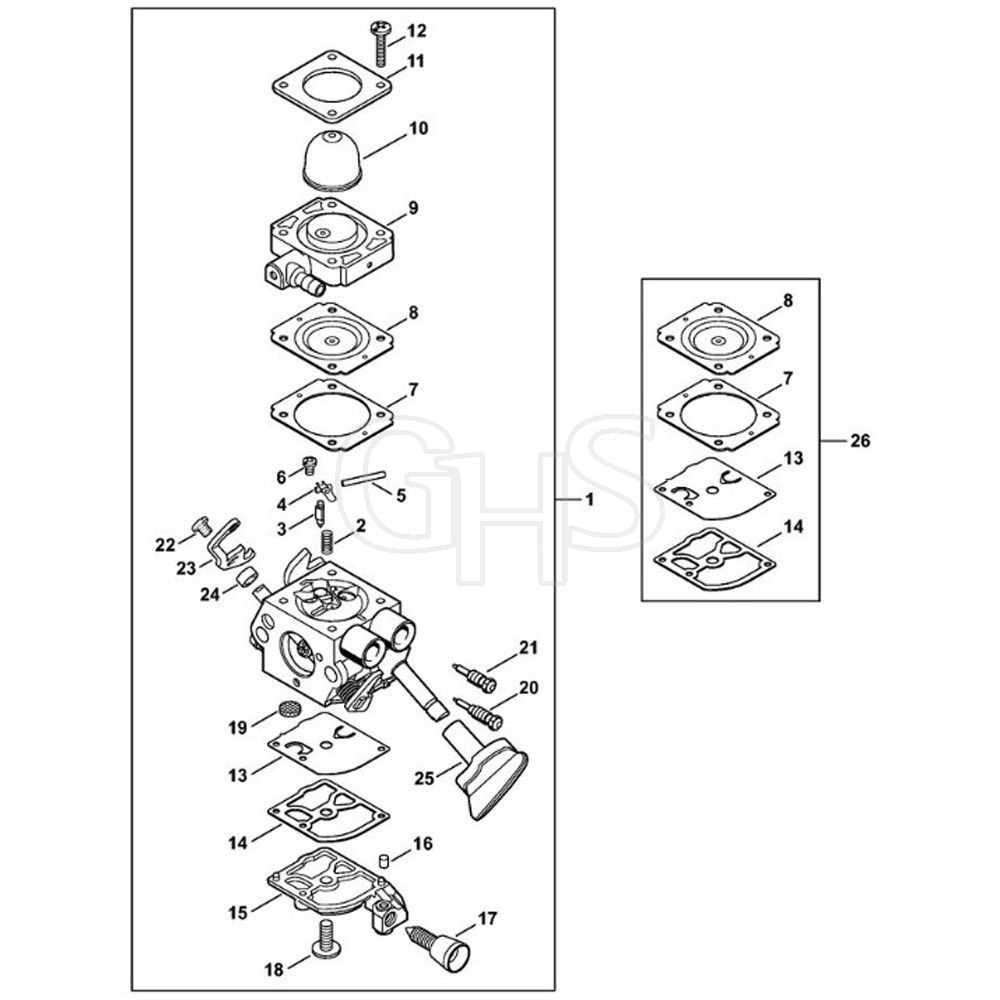

Understanding a blueprint for a chainsaw is essential for anyone who needs to repair or maintain the tool. These blueprints provide a detailed view of each component, helping users visualize the internal structure. Being able to interpret these illustrations accurately is crucial for identifying parts, their connections, and potential issues that may require attention.

Breaking Down the Blueprint

Typically, these blueprints will categorize components into groups, such as the engine, fuel system, and cutting mechanism. Each section will have numbered parts with corresponding labels. Here’s how to approach reading the blueprint:

- Engine Components – Identifying the key engine parts, like the carburetor and spark plug.

- Fuel System – Recognizing elements like the fuel tank, fuel lines, and filters.

- Cutting Assembly – Understanding the connection between the chain, bar, and drive mechanism.

Interpreting the Labels

Each part is usually marked with a specific number that corresponds to a part list. Reading these numbers is straightforward, and it’s helpful when searching for replacements. Often, these labels also include part names and sometimes dimensions, which further aid in identification.

Essential Components for Chainsaw Repair

When it comes to repairing a chainsaw, understanding the core components is vital. Some parts are more prone to wear and tear, and recognizing these will help ensure smooth and effective repairs. Regular maintenance or replacement of these elements ensures the longevity of the tool and keeps it functioning at its best.

Critical Engine Elements

The engine is the heart of the chainsaw, and understanding its components is key to repair. Key parts include the ignition system, carburetor, and spark plug. Regular checks and cleaning of these parts can prevent most engine-related issues.

- Ignition System – Ensures the engine starts and runs smoothly.

- Carburetor – Regulates the fuel and air mixture for proper engine performance.

- Spark Plug – Delivers the spark that ignites the fuel mixture.

Fuel and Cutting Mechanism

The fuel system and cutting components also require attention. The fuel tank, fuel lines, and air filter often need to be cleaned or replaced to maintain optimal performance. Similarly, components of the cutting mechanism, such as the chain, bar, and clutch, should be inspected regularly for wear and damage.

- Fuel Tank – Stores the fuel required for the engine.

- Air Filter – Prevents debris from entering the engine, ensuring clean combustion.

- Chain and Bar – Responsible for the cutting action, these parts need regular maintenance to avoid breakdowns.