Maintaining machinery requires a clear understanding of its individual components and how they work together. A detailed breakdown of each part helps ensure smoother operations and more effective repairs. This guide provides an in-depth look at the crucial elements of a popular model, focusing on their arrangement and functions.

By examining the system structure, users can identify potential issues and know exactly which parts need attention. Whether you’re replacing a worn-out component or performing routine maintenance, understanding the layout enhances overall efficiency.

In the following sections, we’ll explore how to interpret the various labels and symbols associated with the system, making it easier for both beginners and experienced users to handle repairs or upgrades. Knowledge of each part’s role will give you the confidence to work with the equipment effectively.

Understanding Mower Component Layout

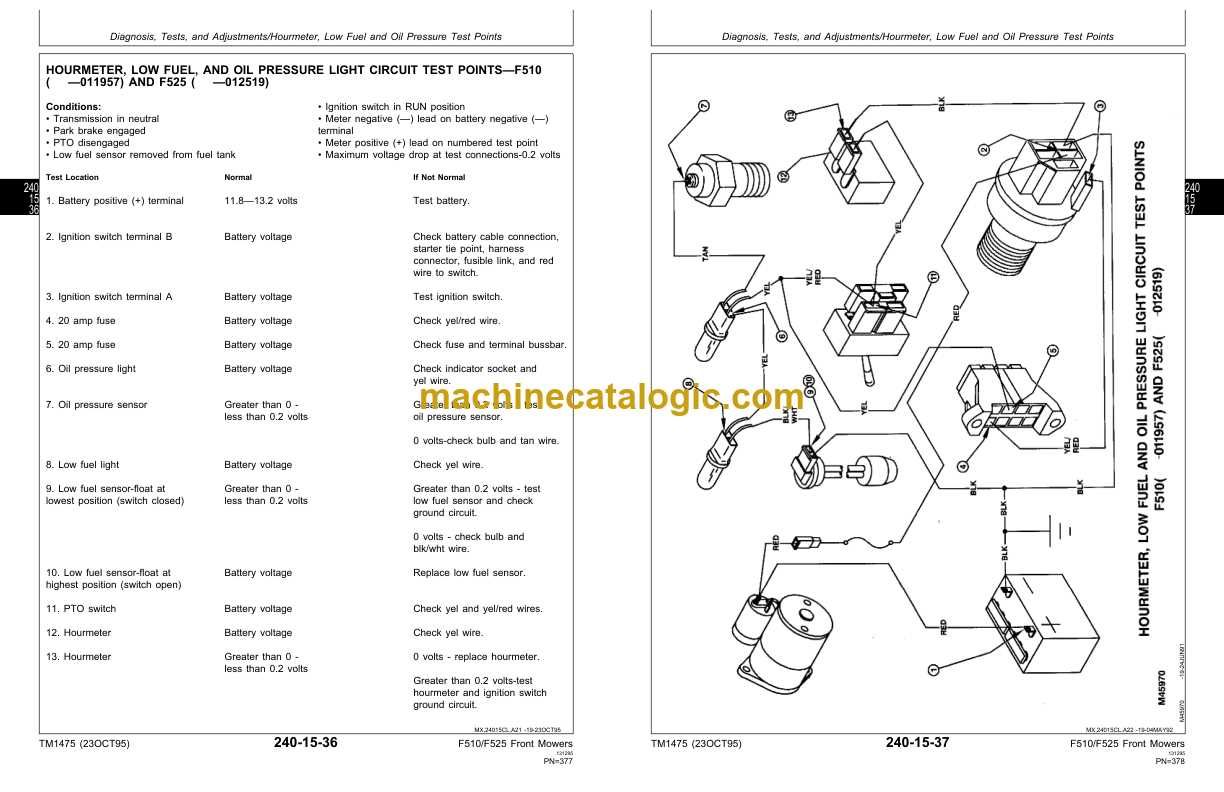

Every piece of machinery relies on a specific arrangement of essential components that work together to ensure optimal performance. Recognizing how these parts interact is crucial for effective troubleshooting and maintenance. A detailed illustration of the system’s structure makes it easier to identify and replace worn-out elements or address malfunctions.

Each section of the layout highlights a different aspect of the machine, from the engine to the control system. By understanding these visual representations, users can quickly locate key components, such as belts, blades, and fuel lines, allowing for faster repairs and fewer errors during maintenance. Knowledge of each part’s function plays a vital role in extending the lifespan of the equipment.

When you analyze the layout, consider the interconnections between components and how the system depends on each part to function smoothly. This insight provides a more efficient approach to handling issues, enabling users to perform repairs with confidence and precision. Having a clear understanding of the overall structure can save both time and money in the long run.

Key Components of Mower

Understanding the essential elements of a machine is fundamental to ensuring its performance and longevity. Every model features a set of key components that work in unison to drive the system. Identifying these main parts allows users to focus on what needs maintenance or replacement, ensuring smoother operation.

Among the crucial parts are the engine, which powers the entire system, and the cutting mechanism, responsible for delivering precise results. The drive system plays an equally important role, transferring power from the engine to the wheels or blades. Additionally, the control system, including switches and levers, ensures the operator has full command over the equipment.

Each of these elements has a distinct function but relies on the others for optimal performance. Regular inspection and understanding of these key components will help extend the life of the machine and prevent costly repairs.

How to Use the Mower Component Breakdown

Utilizing a detailed layout of a machine’s components is a vital tool for maintenance and repairs. This visual guide allows users to identify individual parts, understand their connections, and spot potential issues more efficiently. By familiarizing yourself with the breakdown, you can ensure that each element of the system is in good working order.

When consulting the illustration, start by locating the main components, such as the engine and cutting system. Pay attention to the labels and numbers that correspond to specific parts, as they make identifying the correct components easier. Each part is typically grouped by its function, making it straightforward to navigate and find the section you’re looking for.

For a more hands-on approach, use the layout to plan replacements or repairs. Cross-reference the components with the model’s manual to confirm compatibility, and always ensure you have the correct tools on hand before starting. Using this resource effectively will lead to quicker fixes and prevent unnecessary delays during maintenance tasks.