The efficient functioning of gas flow systems relies on several essential elements working in harmony. These components play a crucial role in controlling and directing the flow of gases to ensure safety and precision in various applications. A clear understanding of how these components interact is vital for anyone responsible for maintenance or troubleshooting such systems.

Identifying each element is the first step in grasping their role within the system. While some parts are responsible for regulating pressure, others ensure a steady supply and prevent any malfunctions. By examining the different sections and their connections, one can gain valuable insights into the overall performance and reliability of the equipment.

Knowing how to spot potential issues with each component can save both time and resources. Common problems often arise from wear, improper connections, or external factors that affect functionality. Proper inspection and timely maintenance are key to avoiding costly repairs and ensuring continuous operation.

Understanding Gas Flow Control Systems

The function of any gas flow control system is to ensure the precise delivery of air or other gases under specific conditions. This involves controlling the pressure, regulating flow rates, and maintaining the stability of the system for safe and effective use. In various applications, from medical devices to industrial equipment, the role of these systems is crucial for optimal performance and safety.

At the core of these systems are mechanisms that manage the delivery pressure and volume, making sure that the flow meets the required standards. These components work together to adjust the pressure based on external factors, maintaining consistency even as demand changes. Their role goes beyond just delivering gas; they ensure that the flow remains within safe limits for different environments and applications.

Understanding how each element contributes to the overall function can help identify potential issues. From faulty seals to blockages, the system’s performance may be compromised if one of the components fails. Regular monitoring and maintenance of each part will prevent these failures and ensure continued efficiency.

Key Components of Gas Flow Control Systems

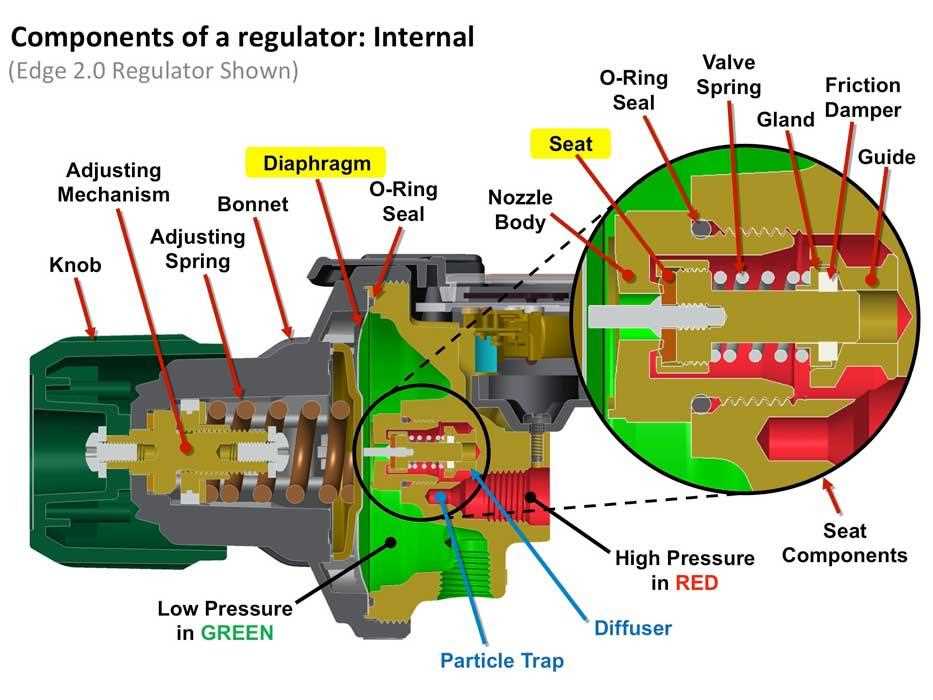

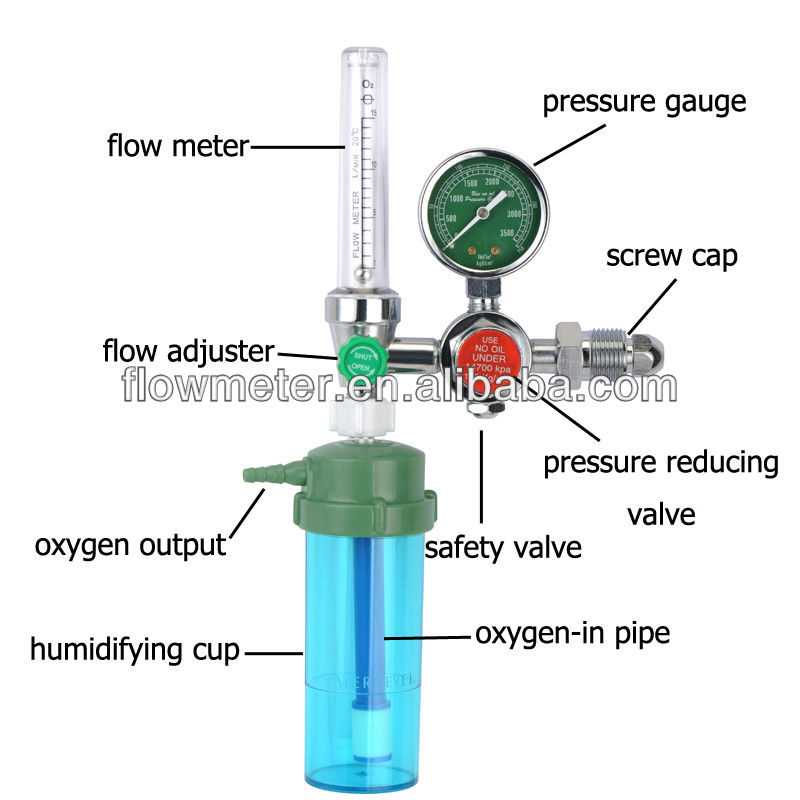

Within a gas delivery system, various critical components work together to ensure proper flow management and pressure control. Each element plays a unique role, contributing to the safe and efficient operation of the system. These components must be carefully designed to handle specific pressures and volumes, ensuring that the gas is delivered under optimal conditions.

One of the essential components is the pressure adjustment mechanism, which regulates the force at which the gas is dispensed. This part ensures that the pressure remains steady, even as external conditions fluctuate. Another important piece is the flow control valve, responsible for adjusting the volume of gas released based on system requirements. Additionally, filters and seals help maintain the purity and integrity of the gas, preventing contaminants from entering the system.

Finally, connection fittings ensure that all components are securely joined, maintaining the system’s integrity and preventing leaks. Proper inspection and maintenance of these parts are crucial for maintaining the system’s reliability and avoiding operational disruptions.

Common Issues and Maintenance Tips

Gas flow systems, like any complex mechanical setup, can experience issues over time due to wear and tear, improper use, or environmental factors. Identifying and addressing these issues early can save both time and resources, ensuring that the system operates efficiently and safely. Regular maintenance is key to extending the lifespan of the system and preventing costly repairs.

One common issue is pressure inconsistency, which can occur due to leaks or faulty valves. To prevent this, it’s important to inspect the seals regularly and replace any worn-out components. Another issue is clogging, which can occur when dust or debris enter the system. Installing appropriate filters and cleaning them regularly can minimize this problem. Additionally, improper connections can lead to leaks or inefficient operation. Ensuring that all connections are tight and secure will prevent these issues from arising.

Regular inspection and timely replacement of worn parts are essential for maintaining smooth operation. Also, periodic testing of the entire system can help identify potential issues before they cause a system failure.