Knowing the individual components of your blower is essential for effective maintenance and troubleshooting. Each part plays a critical role in the overall functionality and performance of the tool. Familiarity with these elements can help you identify issues quickly and ensure the proper functioning of your equipment.

By examining the assembly layout, you can gain insight into how the various pieces fit together and how they work in harmony. This knowledge is valuable for repairs, replacements, and general upkeep of the device.

Whether you’re a novice or an experienced user, understanding the setup of your blower will simplify any maintenance tasks and extend the life of your tool.

Understanding Blower Components

Each tool is composed of several key elements that work together to ensure its optimal performance. Recognizing the role of each individual component is vital for efficient maintenance and troubleshooting. These components are designed to perform specific tasks, and knowing their functions allows for better care and quicker identification of potential issues.

Key Functional Elements

At the heart of the device, the motor and air intake system play crucial roles in generating power and directing airflow. The motor powers the internal mechanisms, while the intake system ensures that the airflow remains consistent and effective. The body housing the components provides the structure, keeping everything secure and aligned for smooth operation.

Maintenance and Care Considerations

Proper care of each part can prevent premature wear and extend the tool’s lifespan. Regular inspection of the fan, motor connections, and air filters is essential to maintain optimal performance. Routine checks for any obstructions or damage help avoid costly repairs and ensure that the device operates at its peak efficiency.

How to Interpret the Assembly Layout

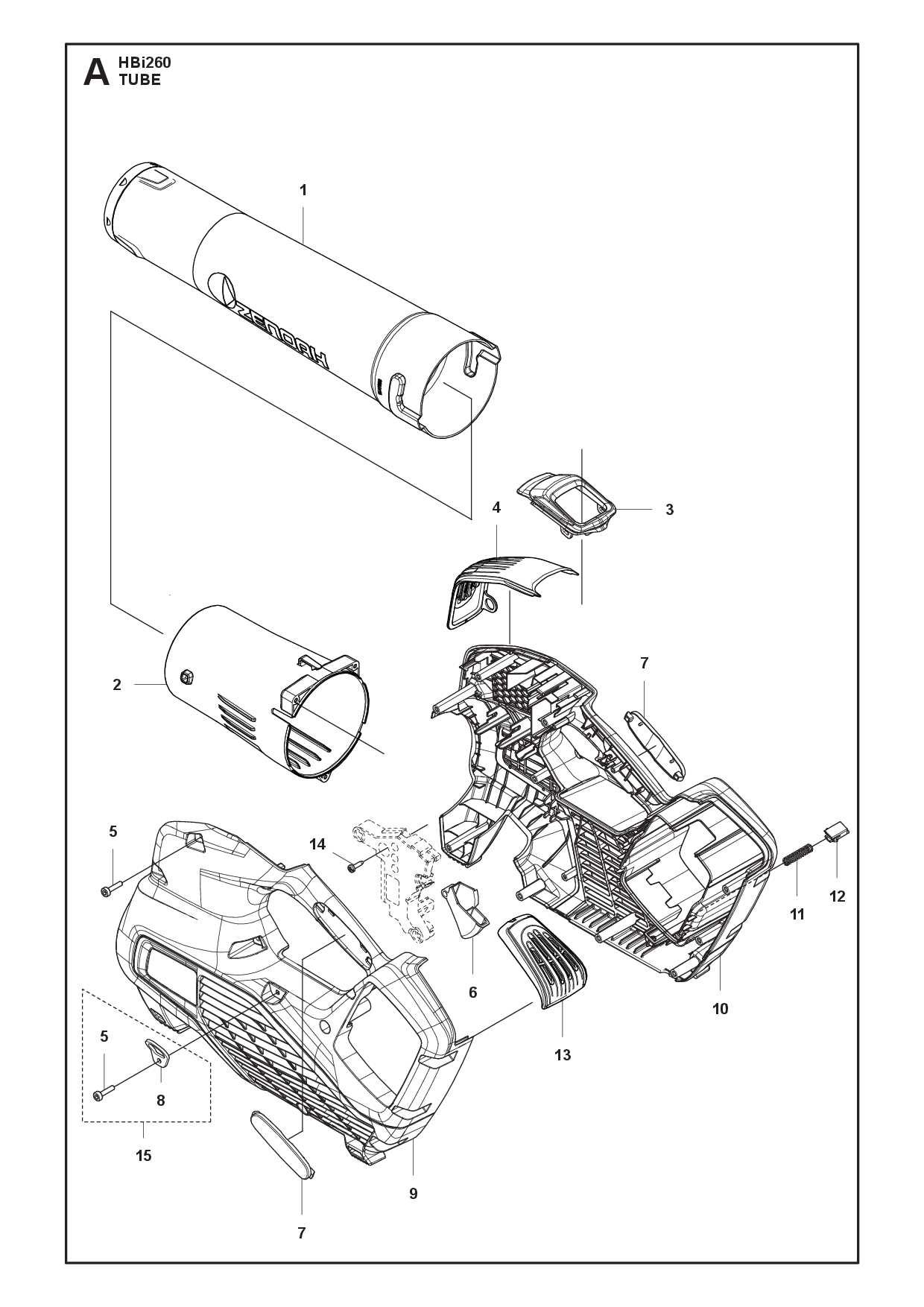

Understanding an equipment’s assembly layout is a vital skill for users who want to carry out repairs or maintenance with ease. These visual guides provide a detailed breakdown of the tool’s structure, helping users identify each component and its placement. Interpreting these layouts allows for better organization when disassembling or reassembling the equipment.

The layout typically shows how each piece connects to the rest of the unit, providing a clear visual reference. By following the guide, you can ensure the correct positioning of elements, which is crucial for efficient operation. It is important to pay attention to numbered or labeled sections that correspond to individual parts, making the process easier and more organized.

Tips for Maintaining Your Blower

Regular maintenance is key to ensuring the longevity and efficiency of your blower. Taking simple steps to care for the equipment can prevent major malfunctions and help maintain optimal performance over time. By focusing on key components, you can easily identify areas that require attention and avoid unnecessary wear.

Clean and Inspect Regularly

Frequent cleaning of the intake and exhaust systems is crucial to prevent blockages and ensure smooth airflow. Regularly inspect the motor housing and check for debris accumulation that might hinder the tool’s operation. Keeping these areas clear will improve performance and extend the lifespan of your blower.

Check for Wear and Tear

Over time, certain parts, such as seals and filters, may experience wear. Regularly inspect these parts for any signs of damage, cracks, or excessive wear. Replacing worn-out components promptly can prevent further damage and ensure that your tool operates effectively without risk of malfunction.