When maintaining or repairing a chainsaw, having a clear understanding of its individual components is essential. Knowing where each piece fits and how they interact ensures optimal performance and longevity. A visual representation of the chainsaw’s structure can be invaluable in these processes.

Identifying each part and its function helps in troubleshooting issues, performing repairs, and replacing damaged components with ease. With the right resources, even novice users can confidently handle basic maintenance tasks and improve the efficiency of their equipment.

Whether you are looking to replace a specific part or simply familiarize yourself with the overall layout, understanding the different sections of the tool will save time and effort. An organized reference is key to getting the job done correctly and quickly.

Understanding the Breakdown of a Chainsaw

Properly identifying the internal components of your chainsaw is critical for maintaining its efficiency and ensuring it functions correctly. Each section of the tool plays a unique role, and knowing how they interact allows for easier troubleshooting and repairs. A thorough understanding of the tool’s construction will enable users to address issues with confidence, reducing downtime and preventing unnecessary damage.

Key Sections of the Tool

The main elements of the chainsaw include the engine, fuel system, cutting mechanism, and safety features. Each of these parts works together to provide smooth and effective operation. Understanding how these components fit into the overall structure allows users to quickly pinpoint problem areas when things go wrong.

Benefits of Familiarizing with the Structure

By familiarizing yourself with the tool’s layout, you will be able to perform routine maintenance and repairs more effectively. This knowledge helps prevent misdiagnosis of issues and ensures that any replacement parts are selected correctly. Moreover, a clear grasp of the setup can extend the life of your equipment by keeping it in optimal condition for longer periods of time.

Identifying Essential Components for Repair

When your chainsaw is not performing as expected, understanding which key components require attention is crucial for an efficient repair process. Different parts of the tool wear out over time, and knowing where to focus your efforts can save both time and money. A clear understanding of the essential elements involved in its operation will help identify areas that need maintenance or replacement.

Common components that often need repair include the engine, chain brake, and fuel system. Each of these elements plays a pivotal role in ensuring smooth operation, and recognizing when they are underperforming or damaged is essential for effective troubleshooting.

Once the primary areas of concern are identified, you can proceed with targeted repairs or replacements, restoring the tool’s functionality. With the right knowledge, even users with minimal experience can quickly address and fix issues, avoiding more costly professional services.

How to Use the Visual Guide Effectively

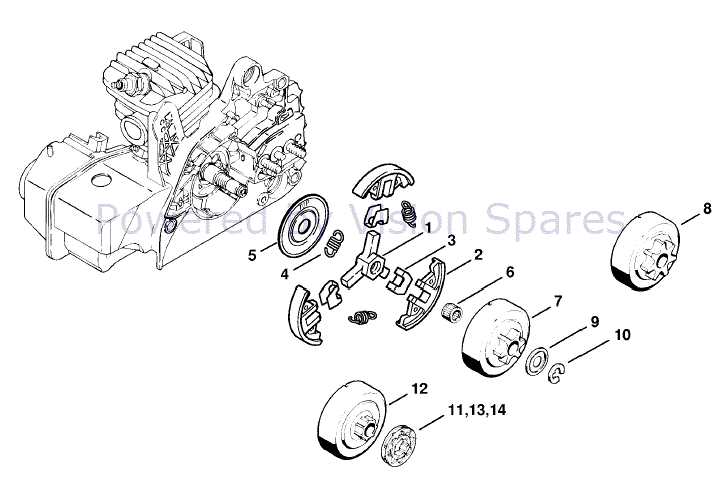

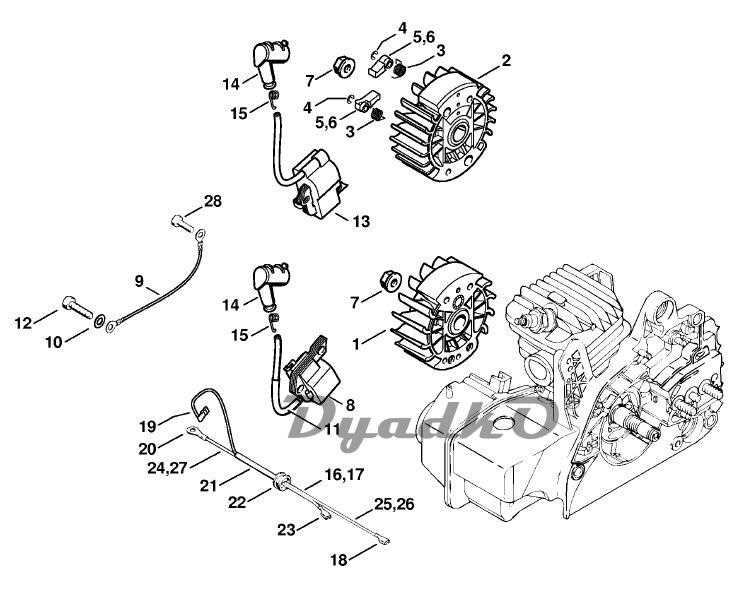

Using a visual guide can significantly improve the efficiency of any repair process by providing a clear and detailed reference for identifying the components of your tool. Knowing how to read and interpret this resource is essential for carrying out successful maintenance tasks. It not only helps you locate the right pieces but also ensures proper assembly after replacement.

Step-by-Step Navigation

Begin by familiarizing yourself with the overall layout of the guide. Each section typically includes labels and numbers that correspond to specific parts. By following these references, you can easily locate the component you need to inspect or replace. A methodical approach will prevent confusion and allow for quicker repairs.

Maximizing the Effectiveness of the Guide

To maximize the effectiveness of this tool, take note of any specific details related to part sizes, compatibility, and installation instructions. Understanding these finer points ensures that you select the correct replacements and assemble them accurately. Proper utilization of this reference minimizes errors and enhances the longevity of your equipment.