For anyone who owns or operates a grass cutting tool, understanding its inner workings is essential for maintaining optimal performance. This guide provides a detailed look at how the various elements of the machine fit together, ensuring proper care and efficient use. Whether you’re replacing worn-out components or performing routine checks, knowing where each part fits is crucial for extending the lifespan of the equipment.

Maintenance and repairs become significantly easier when you have a clear understanding of the machine’s layout. Familiarity with its structure not only speeds up troubleshooting but also helps in making informed decisions when sourcing spare components. Regular upkeep based on a comprehensive understanding of each component will keep your tool running smoothly for years.

Additionally, recognizing the most commonly replaced items and how they interact can prevent unnecessary breakdowns. By identifying parts that are prone to wear, you can prioritize maintenance tasks and avoid more significant issues down the road. This approach ensures that your tool stays reliable and functional when needed the most.

Understanding Trimmer Components

Every piece of equipment is made up of various elements that work together to deliver the desired outcome. Knowing how these components interact is crucial for proper maintenance and efficient operation. By examining the structure and function of each part, users can gain a deeper understanding of how their tool performs its tasks and how to keep it running at its best.

Key Components and Their Functions

At the heart of any trimmer is its engine, which powers the entire system. Surrounding this core are essential components like the handle, cutting head, and drive shaft, each playing a role in ensuring smooth operation. For example, the cutting head holds the line or blade, while the drive shaft transmits power from the engine to the cutting mechanism. Understanding the function of each element ensures you know which parts require regular inspection or replacement.

Identifying Common Issues

When an issue arises, knowing the parts most likely to fail can save time and effort. Common problems often involve worn-out cutting mechanisms, damaged shafts, or issues with fuel flow. By familiarizing yourself with these components, you can quickly pinpoint the cause of a malfunction and address it before it becomes a more significant problem. Regular checks on these key parts can help extend the lifespan of your equipment.

How to Read the Component Layout

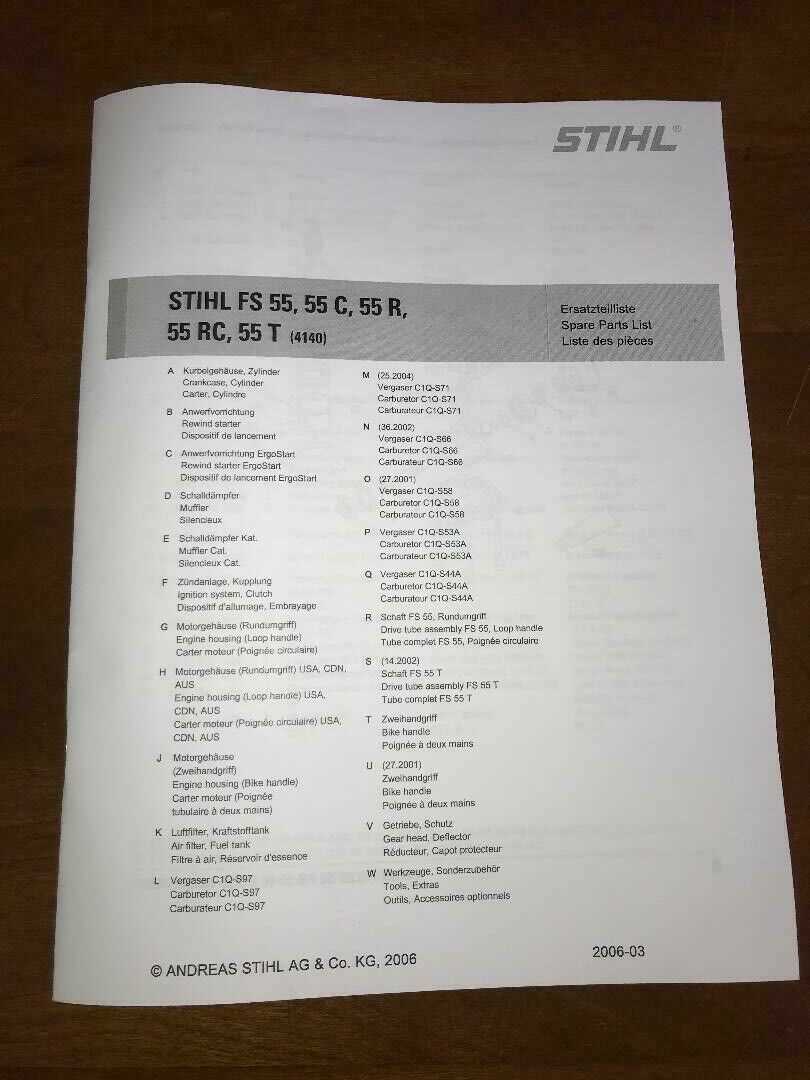

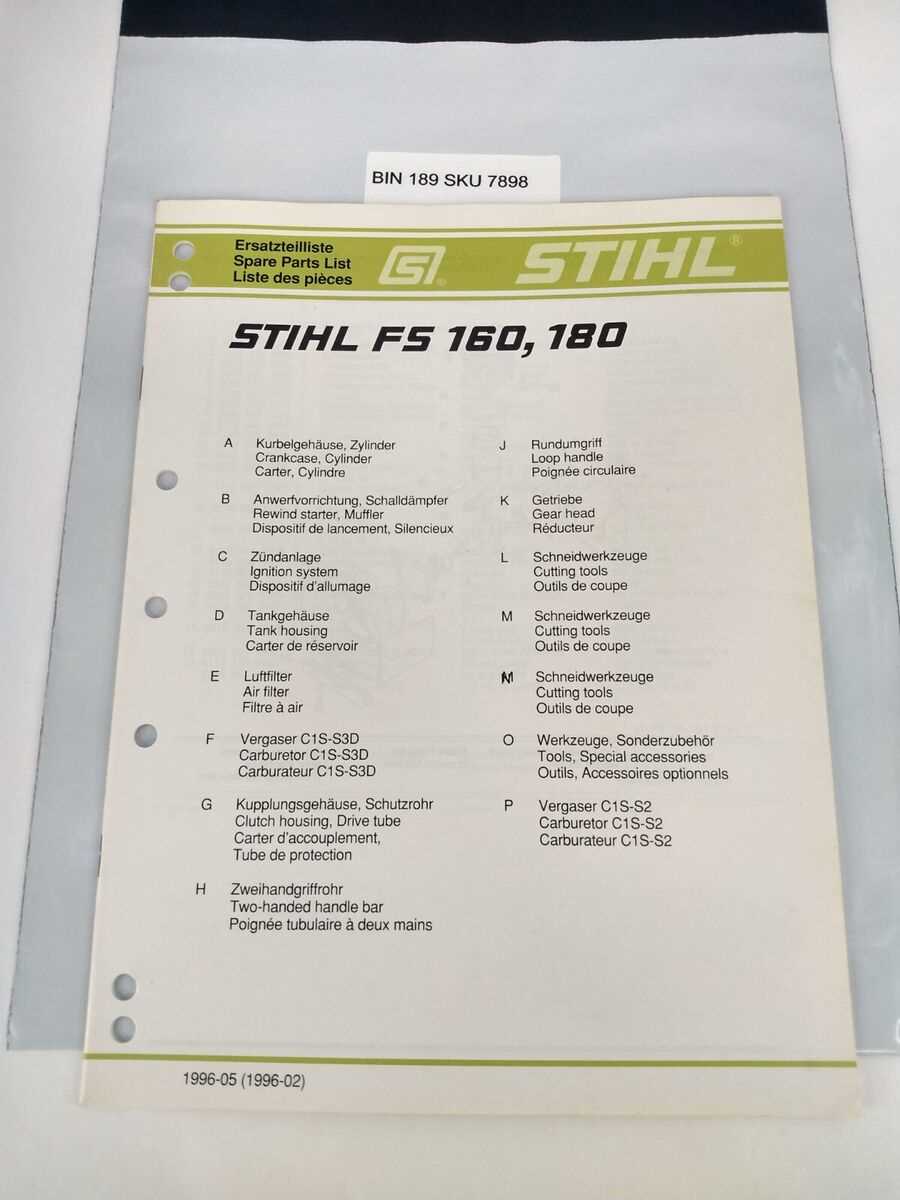

Understanding how to interpret the layout of a machine’s components is an essential skill for anyone looking to repair or maintain their equipment. The visual representation provides a clear guide to the relationships between each part and how they fit together. By mastering how to read these representations, users can quickly locate and identify the exact parts they need for any task.

Interpreting Visual Indicators

Each element in the layout is typically represented with a unique reference number, which corresponds to a detailed list of components. These references help users identify parts and understand their specific function within the machine. Pay attention to the symbols and lines that connect the components, as these indicate how they are assembled and how they work together.

Locating Specific Components

When looking for a specific part, focus on the area of the layout where the part is situated. The clear demarcation of sections can help narrow down the search to particular regions of the machine. If you need to replace or check a part, knowing where it is located in the visual guide makes the process faster and more efficient. Reference lists provide additional clarity on part numbers and compatible components.

Common Replacement Components

Regular maintenance and proper care are essential for ensuring the longevity of your equipment. Over time, certain components may wear down or become damaged and require replacement. Understanding which parts are most commonly replaced allows for efficient upkeep, preventing unnecessary downtime. This section highlights the key components that often need attention and offers guidance on when to replace them.

Cutting Mechanisms

The cutting head is one of the most frequently replaced elements in any grass trimming tool. Over time, the line or blade may become dull or break, requiring replacement. It’s important to check the cutting mechanism regularly and replace it as soon as signs of wear appear. Using high-quality replacement lines ensures consistent performance and reduces the frequency of changes.

Drive Shaft and Engine Components

Another common issue involves the drive shaft, which transmits power from the engine to the cutting mechanism. Wear and tear on this component can lead to a loss of efficiency or even malfunction. Regular checks of the drive shaft and other engine components, such as the fuel filter and spark plug, help maintain smooth operation. Replacing damaged shafts and other engine parts early can prevent further damage and improve overall performance.