When it comes to maintaining cleaning equipment, knowing the individual components is essential for ensuring smooth operation and efficient performance. Whether you’re troubleshooting an issue or performing routine maintenance, recognizing each element’s role helps you handle the machine properly.

Identifying specific parts and understanding their functions is crucial in preventing malfunctions and extending the life of the equipment. A thorough knowledge allows for easier repairs and minimizes downtime, making it an invaluable skill for anyone who regularly uses cleaning machinery.

In this guide, we will break down the essential parts of cleaning devices, focusing on how to recognize and address common issues. Having a clear understanding of these elements can save time and resources when issues arise.

Understanding the Key Power Washer Components

Effective cleaning machines rely on a variety of key elements that work together to produce the desired outcome. Each component plays a distinct role in ensuring optimal performance and efficiency. To fully appreciate how these machines function, it’s essential to identify and understand these critical parts.

The Core Elements of Cleaning Equipment

At the heart of the machine are several important components, each responsible for a specific task. From the motor that powers the system to the nozzles that direct the flow, understanding these elements allows users to recognize how each contributes to the overall function. Regular inspection and maintenance of these elements can help prevent wear and tear, extending the machine’s lifespan.

How Each Component Interacts

All the components are interconnected, and one malfunctioning part can affect the entire system’s performance. For example, issues with the pressure mechanism can drastically reduce the cleaning effectiveness. It’s crucial to understand how these elements interact and how they contribute to the machinery’s overall performance, so users can address problems more effectively when they arise.

How to Identify Parts in a Diagram

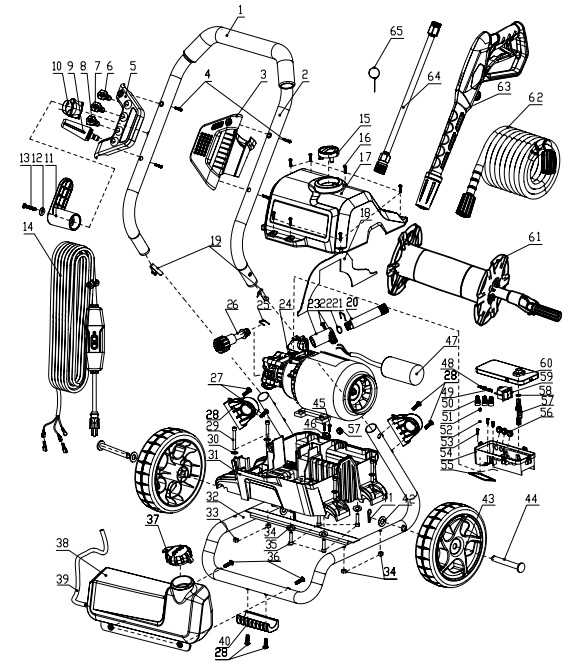

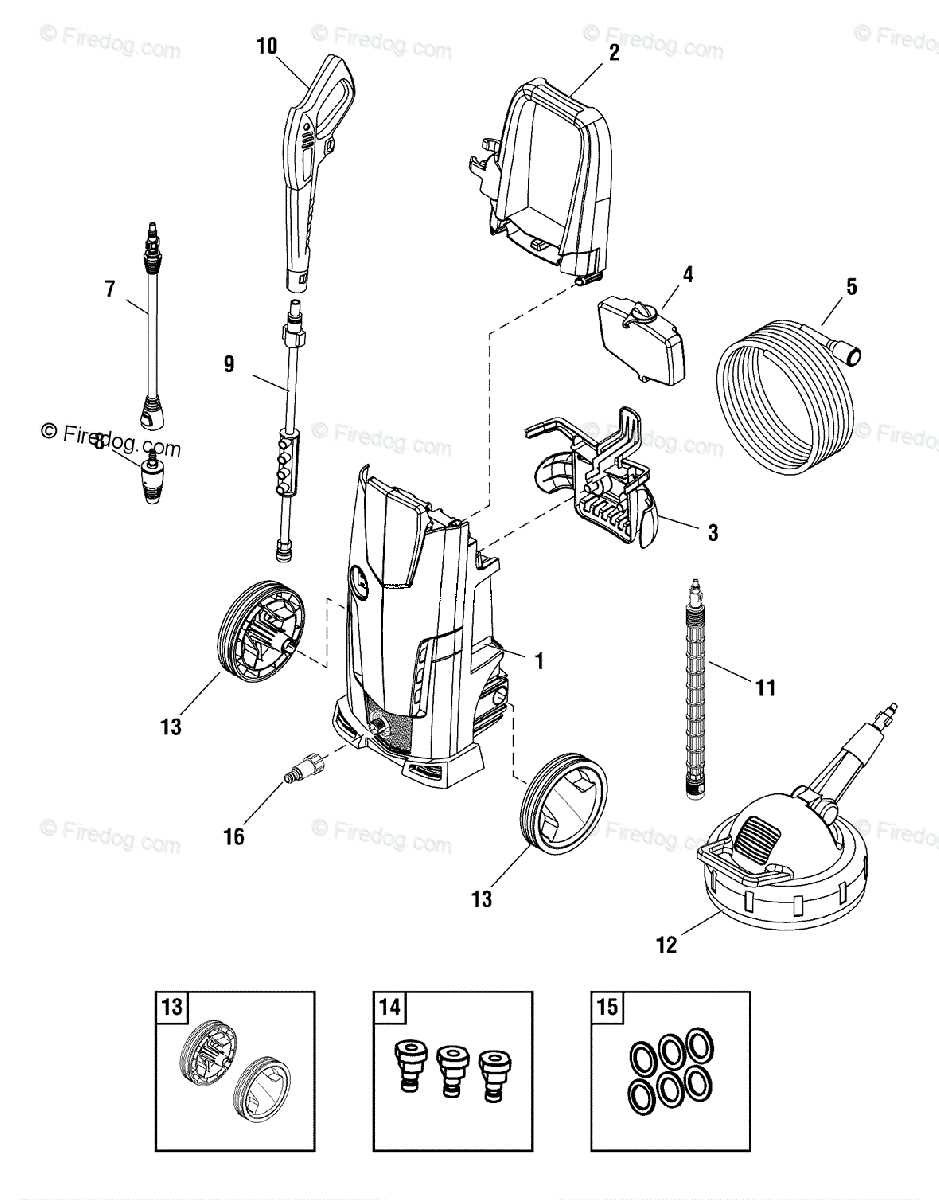

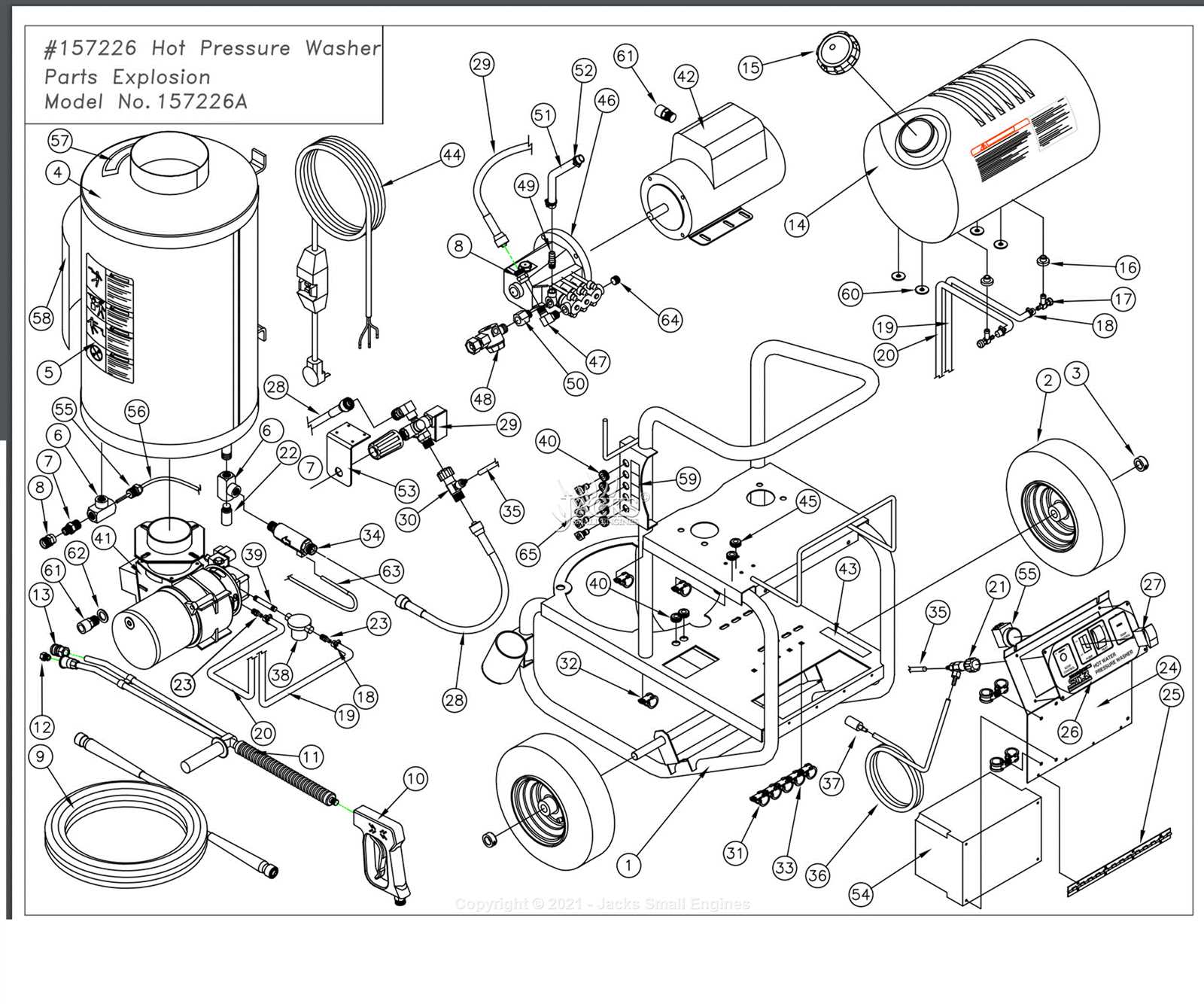

Recognizing individual components within a visual representation of a cleaning device can greatly enhance your understanding of its structure and function. A clear and detailed illustration helps pinpoint the key elements, making it easier to troubleshoot, maintain, or replace parts when necessary.

To accurately identify each component, begin by familiarizing yourself with common symbols or labels used in the diagram. These markings often indicate specific features or mechanisms, allowing you to trace their functions within the overall system. Pay attention to the connections between each part, as these relationships can reveal the flow and operation of the equipment.

When studying the image, take note of the size, shape, and placement of each element. This will assist you in distinguishing between similar-looking components. Understanding the layout and interconnections will help you quickly spot issues and make informed decisions during repairs or maintenance.

Common Issues with Power Washer Parts

When using cleaning devices, several common problems can arise due to wear and tear on key elements. Understanding these issues can help in identifying the source of a malfunction and ensuring proper maintenance to avoid more serious damage.

Clogging is a frequent issue, especially with nozzles and hoses. Over time, debris can build up, obstructing the flow of water or cleaning solution. This can lead to reduced performance and inefficiency. Regularly checking and cleaning these parts can prevent such blockages from occurring.

Another common issue is pressure loss, which often results from a malfunctioning pump or worn seals. If pressure drops, it can significantly affect the cleaning power of the machine. In many cases, replacing or repairing the pump or seal can resolve the issue.

Leaking is also a concern, particularly with connections and hoses. When seals or gaskets wear out, the fluid can escape, resulting in a loss of efficiency and potential damage to other components. Ensuring all connections are tight and seals are intact is vital for maintaining optimal performance.