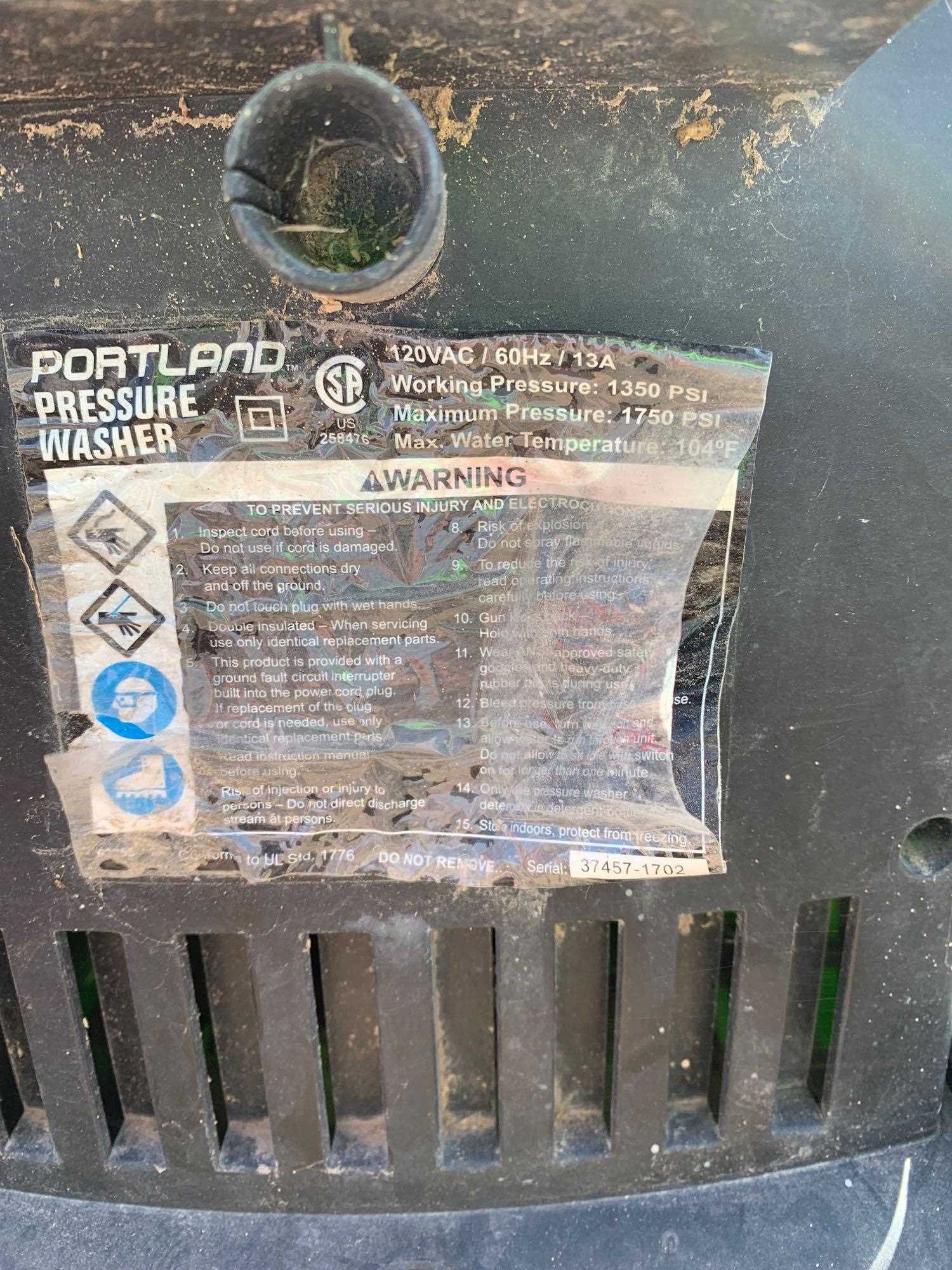

When it comes to maintaining and repairing high-powered cleaning tools, understanding their structure is essential. Every device consists of various elements that work together to deliver optimal performance. Having a clear idea of how these components interact can help users troubleshoot problems more effectively and ensure a longer lifespan for their equipment.

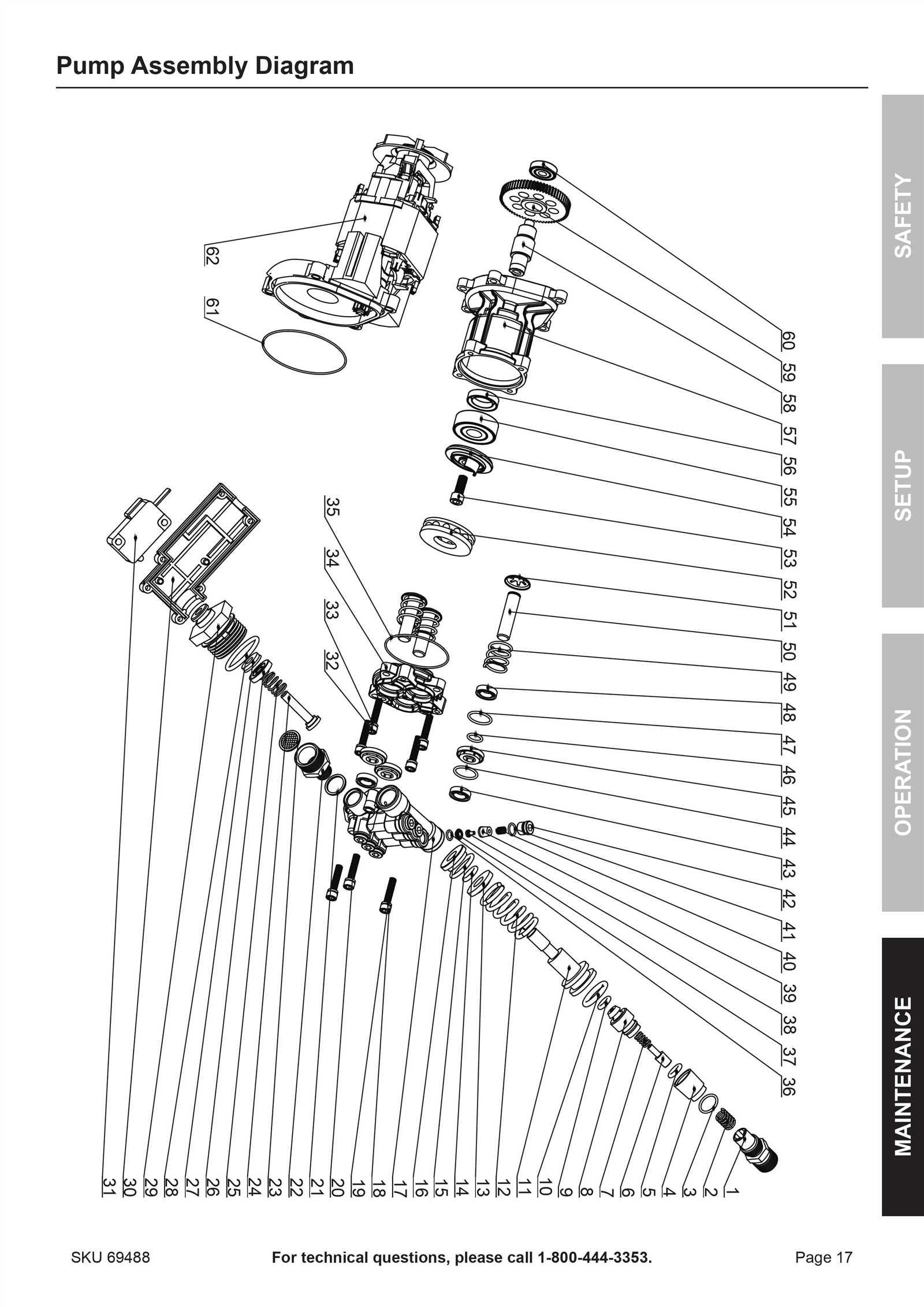

Visual references play a crucial role in identifying specific parts and their functions. A detailed view of these systems allows users to spot wear and tear or other malfunctions early on. This knowledge is particularly valuable when performing routine checks or preparing for necessary repairs.

In this article, we will explore the most important aspects of high-pressure cleaning systems, focusing on their essential components and how they contribute to the overall efficiency. By the end, you will have a deeper understanding of how to care for and maintain your equipment, preventing costly breakdowns and maximizing performance.

Understanding High-Pressure Cleaning Equipment Components

To achieve efficient cleaning results, it is crucial to understand the key elements that make up high-performance cleaning tools. Each component of the system serves a specific function, and the success of the device depends on how well these parts work together. Knowing the role of each part not only helps in troubleshooting issues but also aids in maintaining optimal performance over time.

Main Components of the Equipment

The main structure consists of several key elements such as the handle, trigger, nozzle, and connector. Each piece has been designed for a specific task, from controlling water flow to directing the spray. The handle, for instance, ensures safe operation, while the nozzle adjusts the intensity and type of spray. Understanding how these parts function together ensures users can operate their equipment effectively and safely.

Functionality and Maintenance

Regular inspection and cleaning of individual components help prevent malfunctions and extend the life of the equipment. For example, the nozzle can become clogged with debris, reducing its efficiency. Keeping the internal mechanisms lubricated and free of debris ensures that the device performs at its best. Knowing what each part does makes it easier to identify potential issues early on and avoid costly repairs.

Common Issues with High-Pressure Cleaning Tools

Even with regular use, high-powered cleaning systems can experience various issues that affect performance. These problems often stem from wear and tear, poor maintenance, or damage caused by external factors. Identifying these common malfunctions early allows for quick fixes, preventing further damage and improving efficiency.

Loss of Water Flow

One of the most common problems is a noticeable decrease in water flow or weak output. This can result from blockages in the nozzle or internal hoses. Dirt, debris, or mineral buildup can restrict water flow, leading to inefficient cleaning. Regularly inspecting and cleaning the nozzles and hose connections is essential to avoid this issue.

Trigger or Valve Malfunctions

Another frequent problem is malfunctioning valves or triggers that either get stuck or fail to engage properly. This issue is often caused by corrosion, wear, or accumulation of dirt within the mechanism. To resolve this, it’s important to keep the trigger system clean and lubricated, ensuring smooth operation every time.

How to Maintain Your High-Pressure Cleaning Equipment

Proper maintenance is essential for ensuring the longevity and efficiency of your cleaning system. Regular care not only prevents malfunctions but also enhances performance, allowing the equipment to deliver optimal results every time. By following a few simple maintenance practices, you can avoid costly repairs and keep your tool in top condition.

Start by checking all external connections for leaks and ensuring that the seals are intact. If any part shows signs of wear, replacing it promptly can prevent further damage. Cleaning the components that come into direct contact with water flow, such as the nozzles and hoses, will help avoid clogs and maintain high efficiency.

Another crucial aspect of maintenance is lubrication. Periodically applying a lubricant to moving parts such as the trigger mechanism or valves helps them operate smoothly and prevents premature wear. Additionally, store the equipment in a dry place when not in use to prevent rust and corrosion from developing on metal components.