Maintaining a lawn tractor can be challenging without proper guidance. Understanding the structure and functionality of each component is essential for efficient repair and upkeep. Regular maintenance ensures your equipment runs smoothly and avoids unnecessary repairs.

By familiarizing yourself with the layout of the different parts, you can identify potential issues before they become major problems. Knowing where each component fits into the larger machine allows you to troubleshoot more effectively and make repairs with confidence.

In this guide, we will explore key details to help you understand how to identify, replace, and maintain various sections of your tractor. Proper knowledge of these areas is vital for extending the lifespan of your equipment and ensuring optimal performance throughout the year.

Understanding the John Deere 345 Parts

To properly maintain your equipment, it’s crucial to have a clear understanding of how each component functions. Knowing the role of every element within the machine allows you to make informed decisions when performing repairs or upgrades. Familiarizing yourself with the structure and placement of these components helps prevent issues that may arise over time.

Each section of the tractor has a specific function that contributes to its overall operation. From the engine to the wheels, each part works together to ensure optimal performance. By learning about the layout and the function of each area, you can identify potential problems early and take the necessary steps to resolve them before they affect the machine’s performance.

Proper maintenance begins with knowing how to recognize signs of wear or malfunction in various sections. Understanding the design and how each element interacts with the others is key to diagnosing issues accurately. This knowledge also empowers you to replace damaged parts effectively, ensuring the machine remains reliable for years to come.

How to Read the Parts Diagram

Understanding how to interpret the layout of your equipment is essential for proper maintenance and repairs. The visual representation of the machine provides a clear guide, showing the placement and connection of each component. Familiarity with this visual aid ensures you can quickly locate and identify sections that require attention.

Identifying Key Elements

The first step in interpreting the layout is recognizing the key components. Typically, these are labeled with numbers or letters that correspond to specific sections of the machine. Some of the main features you should look for include:

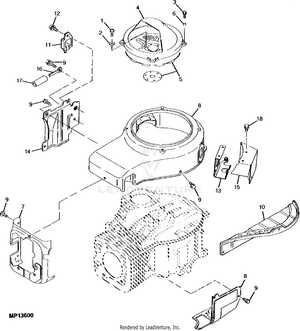

- Engine components – Critical elements that power the machine.

- Transmission – Connects the engine to the wheels.

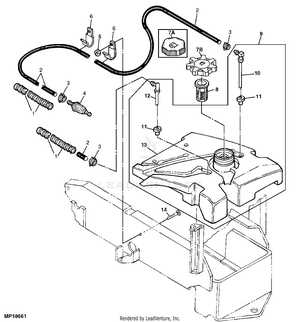

- Fuel system – Stores and supplies fuel to the engine.

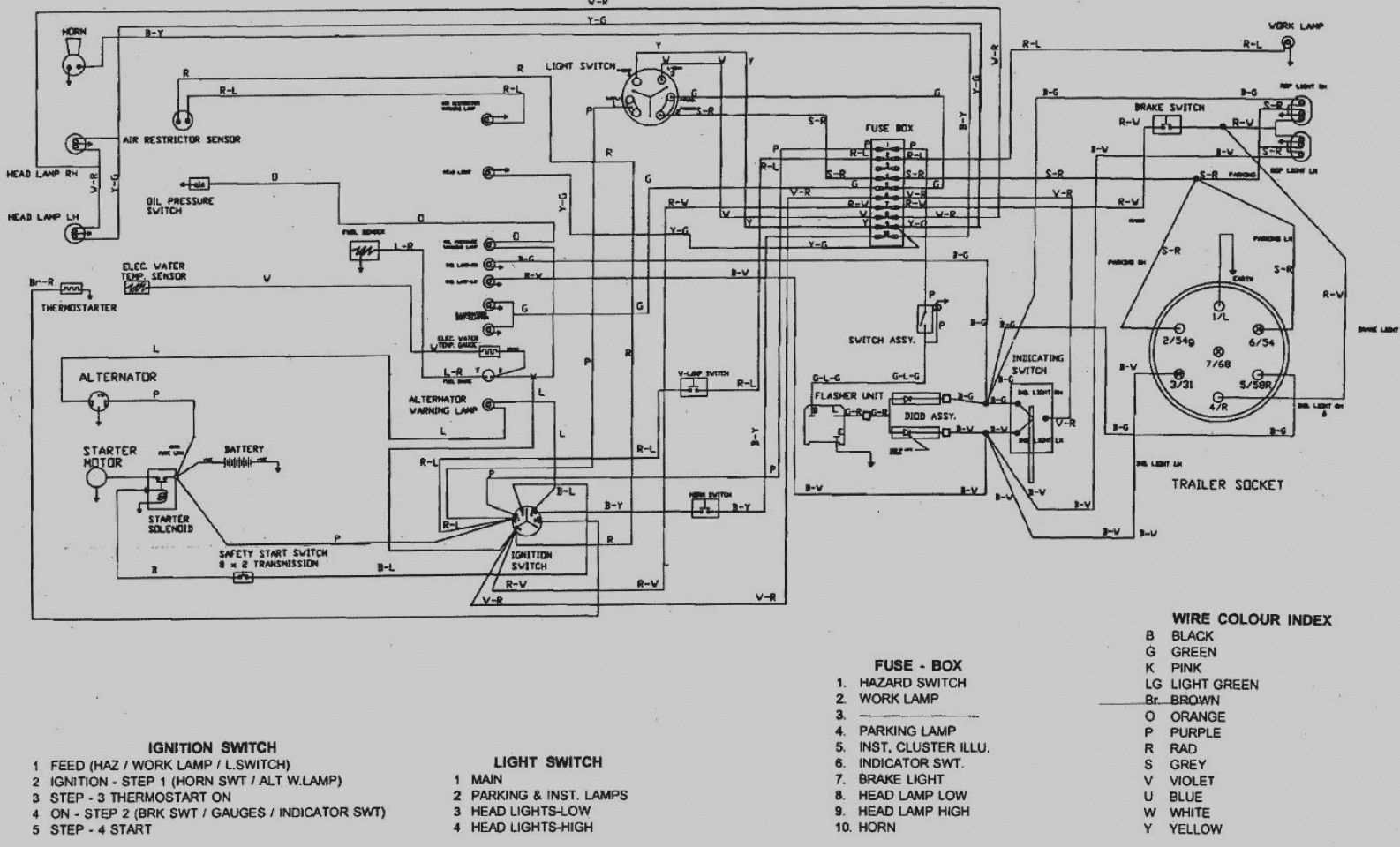

- Electrical system – Powers essential functions such as ignition and lights.

Interpreting the Symbols and Labels

In most diagrams, you’ll find symbols or numbers that correspond to parts and their respective function. Understanding these symbols is crucial for effective maintenance. For instance:

- Numbers often represent specific part codes or reference numbers.

- Arrows indicate the flow of energy or fluid within the system.

- Shaded areas can point to critical areas that require attention.

By learning to recognize and decode these symbols, you can navigate the layout with confidence and perform maintenance tasks accurately.

Common Issues and Solutions for JD 345

Even the most reliable machines can face occasional problems that require attention. Identifying common issues early on can prevent costly repairs and keep your equipment running smoothly. By understanding typical malfunctions and knowing the solutions, you can address problems quickly and efficiently.

One of the most frequent issues is difficulty starting the engine. This could be due to a variety of factors, including a drained battery, faulty connections, or a clogged fuel system. Checking the battery and ensuring all electrical connections are secure is the first step in resolving this issue. If the problem persists, inspecting the fuel lines for blockages or leaks may be necessary.

Another common concern is poor performance during operation. If the machine is not running at full capacity, it could be due to issues with the air filter, spark plugs, or fuel delivery. Replacing a dirty air filter or worn spark plugs can often restore the equipment’s performance. Additionally, checking the fuel system for blockages can help ensure the engine is receiving a steady supply of fuel.

Lastly, problems with the transmission or steering can arise over time. These issues are often caused by worn-out belts or low fluid levels. Regular inspection of the belts and ensuring that the transmission fluid is at the correct level can prevent these problems from becoming more serious. If the steering feels unresponsive, it may be due to a loose or damaged steering linkage, which should be adjusted or replaced as needed.