When it comes to keeping agricultural equipment in top shape, understanding its inner workings is essential. A clear and precise breakdown of every element within the machinery can make all the difference when it comes to troubleshooting and repairing. Familiarity with the layout and connections of various parts helps ensure effective maintenance and prevents costly mistakes.

Knowing how to identify each part and understanding their functions within the larger system enables operators and technicians to manage repairs confidently. By referring to a comprehensive visual representation of the equipment, it becomes easier to locate issues, replace components, and avoid unnecessary disassembly.

Whether you’re a seasoned professional or a new owner, mastering the maintenance guide will improve efficiency, minimize downtime, and extend the lifespan of your machinery. Let’s dive into how to interpret and utilize this valuable tool for optimal performance.

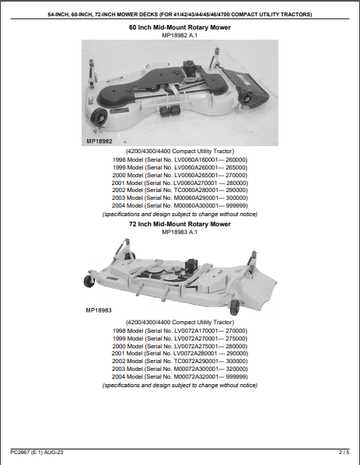

Understanding the Tractor Components

To effectively manage and maintain heavy machinery, it’s crucial to understand the various components that make up the system. Every individual element plays a vital role in ensuring the machine operates smoothly. From the engine to the smaller attachments, each part must function in harmony for optimal performance.

Familiarizing yourself with the layout of the equipment allows for easier troubleshooting and quicker identification of potential issues. Knowing where each component is located and understanding its specific function can drastically reduce repair time and improve maintenance procedures. Whether you’re dealing with the transmission, hydraulic systems, or electrical components, each part serves a unique purpose in the overall operation.

Having a comprehensive guide to these components can assist in decision-making, whether it involves repairs, upgrades, or replacements. Understanding the relationship between the various sections helps in identifying weaknesses, planning repairs, and ensuring that every element is working at peak efficiency.

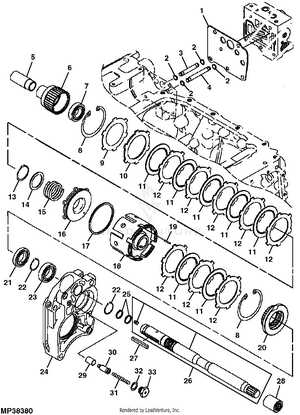

Key Components in the Breakdown

Every heavy-duty machine is made up of a collection of integral components, each serving a specific purpose in the overall functionality. Understanding the essential sections within the system helps operators and technicians effectively manage repairs and maintenance. These key elements work together to ensure smooth operation, and knowing their roles is crucial for troubleshooting.

Some of the most important components include:

- Engine Assembly: The heart of the machinery, responsible for powering the entire system.

- Transmission System: Allows for the transfer of power from the engine to the wheels, ensuring proper movement.

- Hydraulic Mechanisms: Control the lifting and movement of attachments and implements, offering versatility to the equipment.

- Electrical System: Powers the machine’s electrical functions, including lights, sensors, and control units.

- Chassis and Frame: Provides the foundation and support for all other parts, offering stability and strength.

These components, when understood and maintained, help keep machinery in peak condition, reducing the risk of downtime and costly repairs.

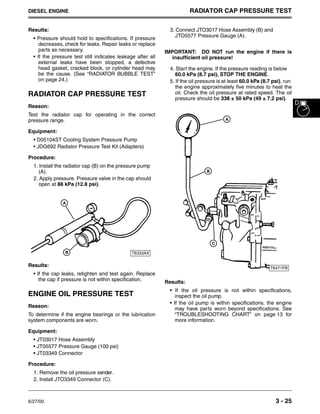

How to Use the Breakdown Effectively

Using a comprehensive breakdown of machine components is a valuable tool for maintenance and repairs. It allows you to quickly locate and identify each part, ensuring that any issue can be resolved efficiently. By referring to such a guide, you can minimize mistakes and save time during the repair process.

To make the most of this resource, follow these steps:

- Identify Key Sections: Start by familiarizing yourself with the major components of the machine. This will give you a clear understanding of the system’s structure.

- Locate Problem Areas: If something isn’t functioning correctly, use the guide to find the specific component that might be causing the issue.

- Check for Connections: Examine how parts are connected. Knowing which parts interact with others can help in troubleshooting and prevent unnecessary disassembly.

- Order the Correct Parts: Once you’ve identified the problematic component, the breakdown will help you order the right replacement quickly.

By mastering this process, you’ll ensure that repairs are done correctly the first time, improving the longevity and performance of your machine.