Efficient functioning of water circulation systems relies heavily on the various internal components that work together to ensure smooth operation. Each element has a specific role and contributes to the overall performance of the system. Understanding how these components interact with one another is crucial for proper maintenance and troubleshooting.

Proper knowledge of each mechanism allows owners to diagnose common issues, optimize energy use, and extend the lifespan of the equipment. Regular checks and timely repairs can prevent unnecessary breakdowns and enhance system efficiency.

Familiarizing yourself with these systems and their functions is essential, whether you are a homeowner or a professional technician. It provides valuable insights into the intricate workings of the machinery, making it easier to identify and address potential problems.

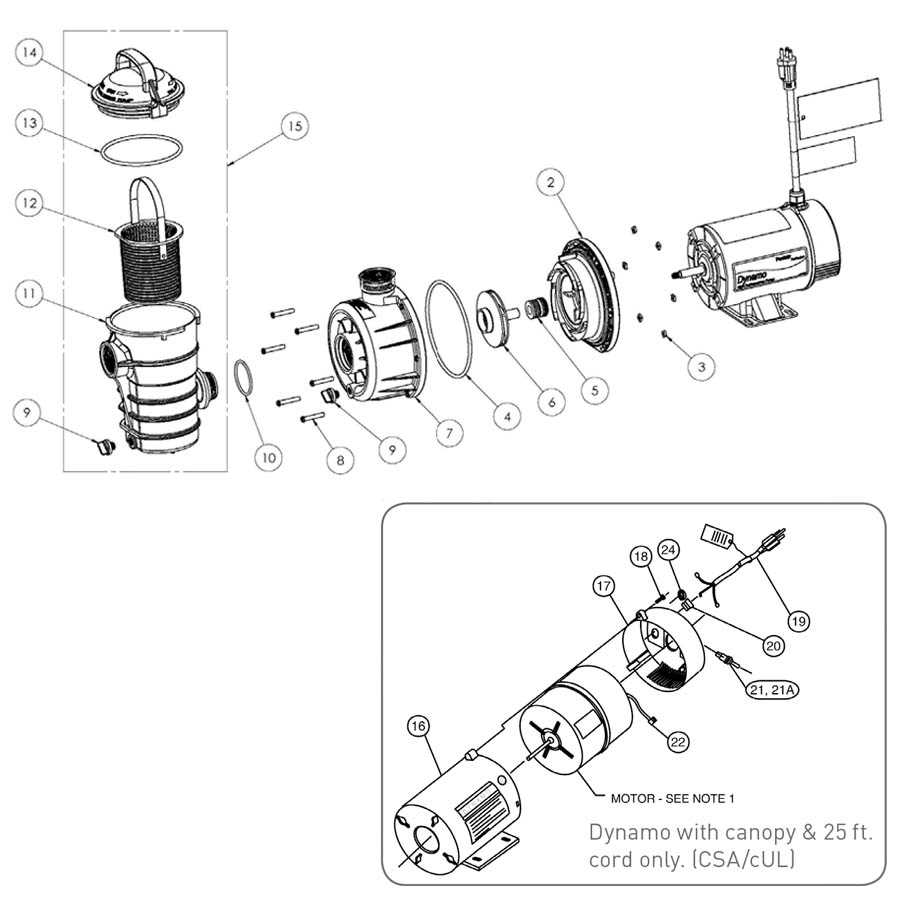

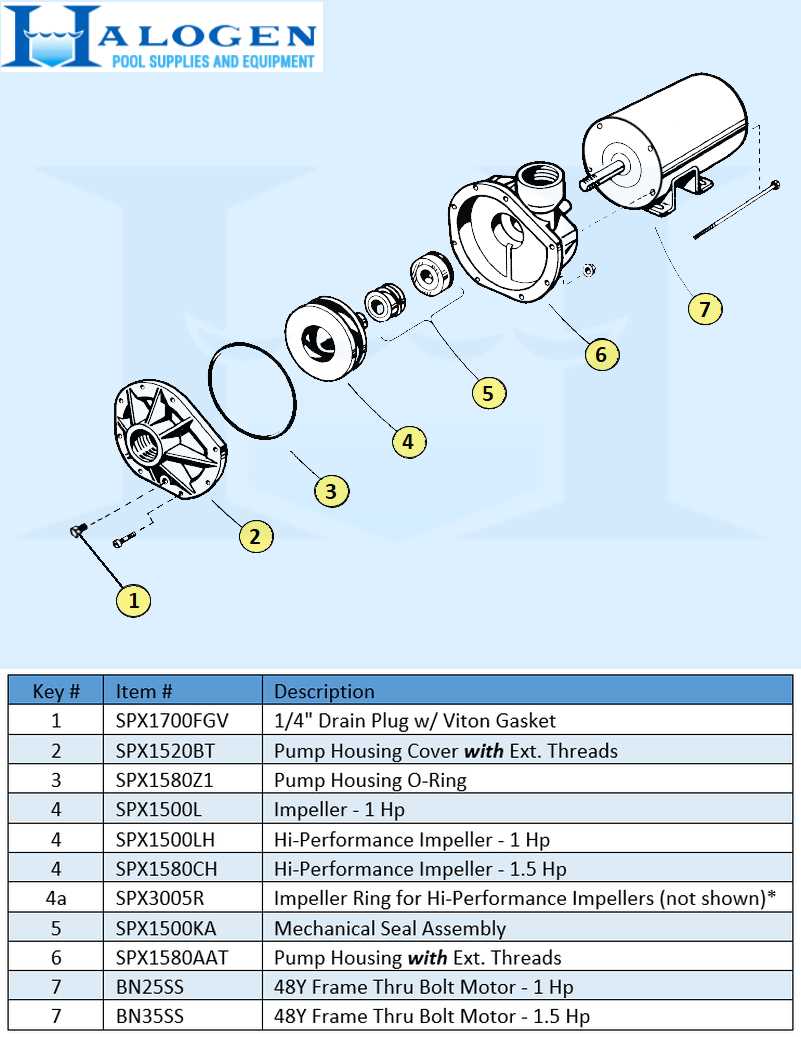

Understanding the Pool Pump Motor Components

The performance of water circulation systems depends on the seamless interaction of various components working in harmony. Each element plays a vital role in ensuring the system operates efficiently, and knowing how they function together is crucial for optimal maintenance. These components are designed to withstand continuous operation, but over time, wear and tear may affect their functionality.

Key Elements of the System

There are several key components within the machinery that are responsible for driving the flow of water. These parts must be regularly maintained to avoid disruptions in operation. The most important elements include:

- Electric motor – Provides the power necessary to drive the internal mechanisms.

- Impeller – Directly moves water by transferring energy from the motor.

- Bearings – Allow for smooth rotation and reduce friction in the system.

- Capacitor – Stores and releases electrical energy to assist with the motor startup.

- Shroud – Protects the inner components from external debris and damage.

Maintenance and Troubleshooting Tips

Maintaining the integrity of these components is essential for ensuring the efficiency and longevity of the entire system. Regular inspections and prompt repairs can prevent more serious issues. Here are a few tips:

- Inspect the motor regularly for any unusual noises or vibrations.

- Check the bearings for wear and lubricate them as needed.

- Ensure that the impeller is free from obstructions and debris.

- Test the capacitor to verify that it is functioning properly.

By staying aware of the key elements and performing routine checks, owners can avoid costly repairs and maintain the system’s efficiency for years to come.

How Pool Pump Motors Work Internally

The internal workings of water circulation systems rely on a carefully orchestrated sequence of events. The flow of energy is converted into mechanical motion, driving various components to push water through the system. Each step in this process must function in harmony for the entire mechanism to operate effectively, ensuring proper fluid movement and system efficiency.

At the heart of the operation is the conversion of electrical energy into rotational movement. This process starts when the electrical current flows into the motor, powering the armature. The armature’s rotation is transferred through the shaft to other connected elements, setting the system in motion. As the components rotate, they create pressure that forces water through the system, maintaining flow and circulation.

Understanding this internal process is crucial for identifying potential issues. If one component fails, the entire process may be disrupted, resulting in decreased efficiency or even system breakdowns. Regular maintenance and awareness of how these systems function can help prevent such issues and ensure optimal performance.

Common Issues with Pump Motor Parts

Even with regular maintenance, internal mechanisms can encounter problems that affect the overall performance of the system. These issues often arise from wear and tear, environmental factors, or improper usage. Understanding the common problems that can occur with key components is essential for diagnosing issues quickly and efficiently.

Electrical failures are among the most frequent problems, typically caused by faulty wiring or a malfunctioning capacitor. These failures can prevent the system from starting or cause intermittent operation, leading to inconsistent performance.

Another common issue is bearing wear, which can result in unusual noises or vibrations. Over time, the bearings may become damaged, causing friction and reducing the system’s efficiency. In severe cases, it may lead to overheating or complete failure of the internal components.

Clogged or damaged impellers can also cause significant problems. If debris accumulates or the impeller becomes cracked, the flow of water can be disrupted, reducing the system’s effectiveness. This can lead to overheating or increased energy consumption as the system works harder to maintain circulation.

Timely identification and repair of these common issues can prevent further damage, ensuring the system operates smoothly and efficiently for years to come.