Understanding the structure and components of your high-pressure cleaning equipment is essential for proper maintenance and efficient use. A clear illustration of each part’s role can significantly improve the way you handle repairs and upkeep.

Recognizing each element of the device helps users troubleshoot effectively, identifying potential issues early on. Knowing the exact location of each component ensures smooth operation and extends the life of the machine.

By examining the different sections and connections, you gain a deeper understanding of how each part contributes to the overall performance. This knowledge allows for easier replacement and assembly when necessary, minimizing downtime and maximizing functionality.

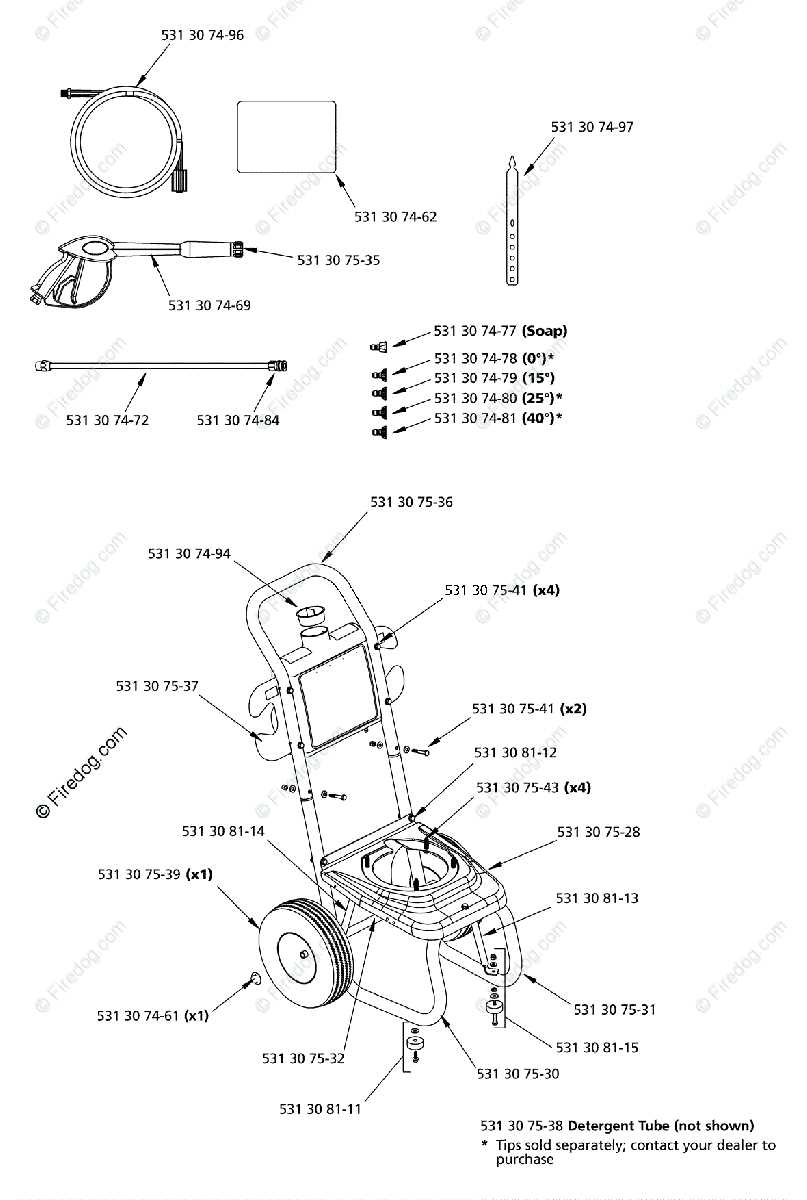

Pressure Washer Component Overview

Understanding the key components of a pressure cleaning machine is crucial for users looking to optimize performance and troubleshoot effectively. Each part of the system serves a specific purpose, and recognizing how they work together ensures proper maintenance and longevity.

Main Functionality of the Core Elements

The central components of the washer include the motor, pump, and nozzle. The motor powers the entire system, while the pump controls the pressure of the water, and the nozzle directs the stream for effective cleaning. Knowing the function of each element helps in diagnosing issues and replacing worn-out parts efficiently.

Additional Supporting Components

Supporting parts like hoses, filters, and connectors play a vital role in maintaining the pressure system’s integrity. These elements ensure that water flows smoothly and that debris does not obstruct the system, leading to consistent and reliable performance.

Identifying Key Components of Pressure Washer

Recognizing the primary components of a high-pressure cleaning system is essential for maintaining optimal performance. Each critical part contributes to the machine’s ability to operate efficiently, and identifying them ensures proper care and quick troubleshooting.

The motor is the heart of the device, powering the system and driving the pump. The pump is responsible for pressurizing the water, and the nozzle controls the flow and direction of the stream. These elements must be regularly inspected for wear and tear to maintain peak functionality.

Additional parts such as the hoses and filters support the smooth operation of the system. Ensuring these are free from blockages or damage helps prevent malfunctions and allows the equipment to function without interruption.

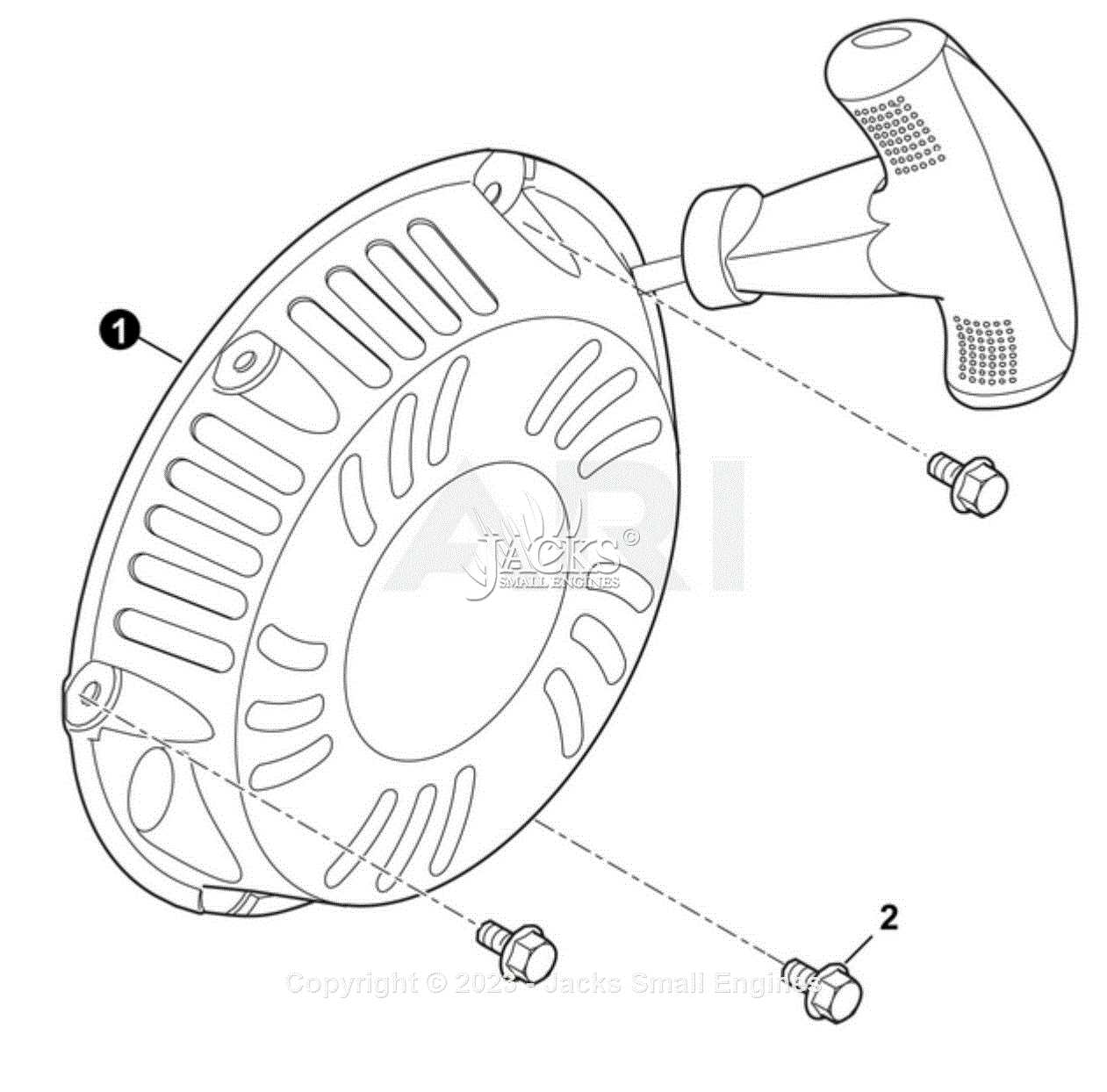

Understanding the Assembly of Pressure Washer

Properly assembling a pressure cleaning system is essential for ensuring its functionality and longevity. Each component fits together to create a seamless operation, and understanding this arrangement can help users avoid errors during setup and maintenance.

The motor connects directly to the pump, which pressurizes the water. These components are typically housed in a durable frame to protect them from damage. The nozzles are attached to the end of the hose, allowing users to adjust the flow for different tasks.

Supporting elements like hoses, filters, and connectors are arranged to ensure the smooth and safe movement of water throughout the system. Understanding how each part interacts allows users to reassemble and maintain the machine effectively.