Every grooming tool consists of multiple interconnected elements that work together to achieve optimal performance. A thorough understanding of these components helps users maintain and repair their devices effectively. Knowing how each part contributes to the tool’s function ensures smoother operation and extends its lifespan.

From motors to blades, each element has a specific role. The interaction between the various components can affect the overall efficiency and quality of performance. A clear comprehension of how these parts work together allows for better handling and troubleshooting of any issues that may arise during use.

Proper care and maintenance are key to ensuring long-lasting functionality. Identifying and understanding each segment enables users to keep their devices in top shape, minimizing wear and tear and preventing costly repairs.

Key Components of Grooming Tools

Each grooming device is made up of several essential elements that contribute to its overall function. These elements are carefully designed to work in harmony, ensuring the tool delivers consistent performance. Understanding these components allows users to identify potential issues and address them before they affect the device’s efficiency.

Motor and Power Mechanism

The motor is the heart of any grooming tool, driving the movement of blades and other components. It is responsible for providing the necessary power to achieve the desired results. Depending on the design, motors can vary in strength and efficiency, influencing the tool’s overall performance and durability.

Cutting Mechanism and Blades

The cutting mechanism, often consisting of high-quality blades, is crucial for precision and effectiveness. These blades are designed to operate smoothly, cutting through hair or fur with ease. Regular maintenance and proper alignment of the cutting mechanism ensure optimal performance, minimizing the risk of uneven results or damage to the device.

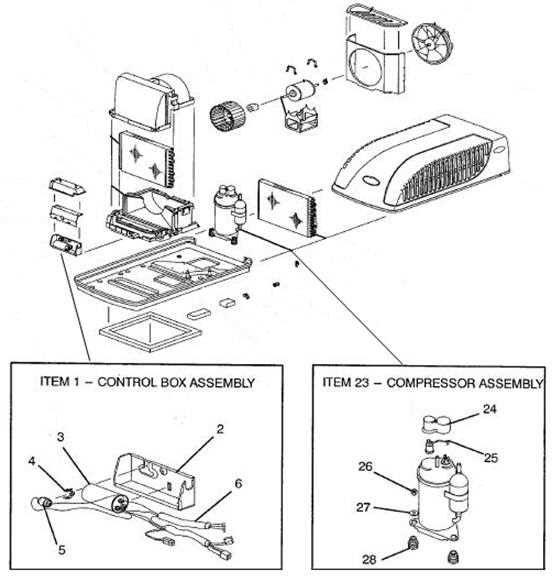

Understanding the Grooming Tool Assembly Structure

The assembly of any grooming device involves multiple elements that fit together to ensure smooth and efficient operation. Each component plays a vital role, from providing power to executing the intended task. Understanding how these parts connect and work in unison is essential for troubleshooting, maintenance, and improving the overall performance of the tool.

Structural Design and Framework

The framework of a grooming tool provides the foundation for all other components. It ensures that each part stays in place and functions properly during use. A well-designed structure is key to durability and the smooth operation of the device, reducing the risk of internal damage and enhancing user experience.

Connection Points and Alignments

Correctly aligned connection points are critical for proper tool function. These connections allow energy to flow between components, such as from the motor to the cutting mechanism. Ensuring that these parts are properly aligned and securely connected helps prevent malfunctions and ensures consistent results with every use.

How Grooming Tools Function Effectively

The effectiveness of a grooming device relies on the seamless interaction of its components, which work together to deliver precise results. The combination of power, movement, and sharpness ensures that the tool performs its intended function smoothly. A clear understanding of how each element contributes to the operation helps users optimize performance and maintain the tool for long-lasting use.

Power Source and Motor Action

The motor serves as the driving force behind the entire device, converting electrical energy into mechanical movement. This energy powers the movement of blades, ensuring that each cut or trim is executed with accuracy. A reliable power source and motor are essential for consistent performance and minimizing interruptions during use.

Cutting and Efficiency Mechanism

The cutting mechanism consists of sharp blades that move at high speeds to trim hair or fur efficiently. To function at their best, these blades must be well-aligned and properly maintained. Factors contributing to effective cutting include:

- Proper blade lubrication for smooth operation

- Correct tension to prevent snagging or uneven cuts

- Regular sharpening to maintain cutting efficiency

When all these factors are optimized, the tool can achieve superior results while minimizing the risk of wear and tear on both the device and the user.

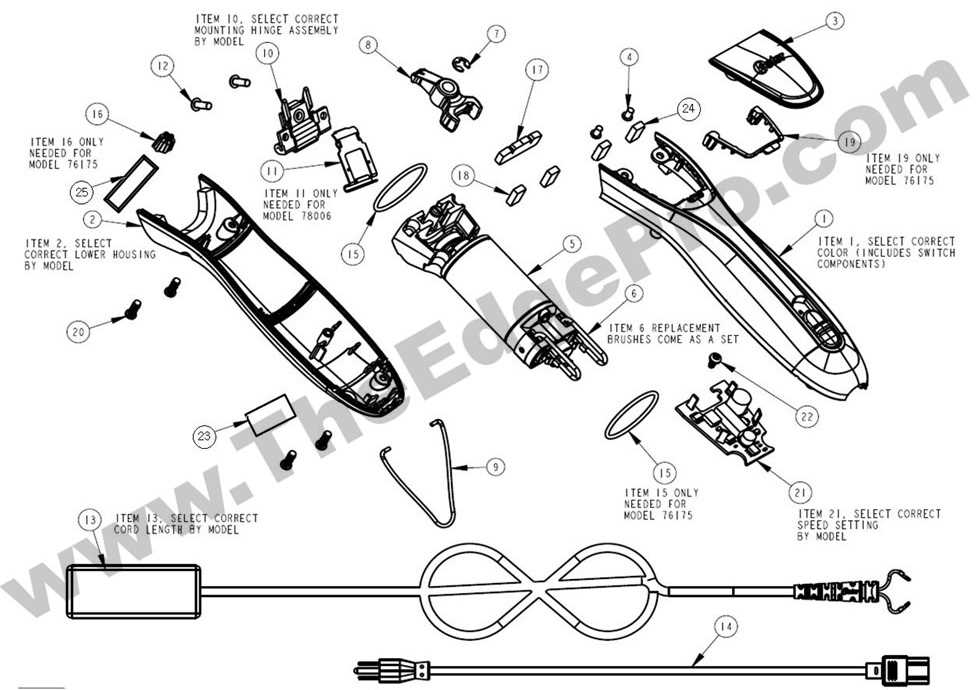

Exploring the Role of Each Part

Each element of a grooming device plays a specific role, contributing to the overall performance and effectiveness. From the power source to the cutting mechanism, understanding how each component functions allows users to better maintain and troubleshoot their tools. The balance between these parts is crucial for the smooth operation and longevity of the device.

The motor is the key to powering the device, converting electrical energy into mechanical motion. It drives the motion of the blades and other components, providing the force needed to complete the grooming task. Without a reliable motor, the device would lack the necessary strength to perform effectively.

The cutting mechanism is responsible for the actual trimming or shaving process. This includes the blades, which must remain sharp and well-aligned for smooth operation. Regular maintenance ensures that the blades function at peak performance, delivering clean and precise results.

Other internal components, such as gears and springs, help facilitate the movement and alignment of the motor and cutting parts. These elements, although often overlooked, are essential in ensuring that the device operates smoothly and efficiently. Maintaining all parts in good condition helps avoid unnecessary strain on any single component.

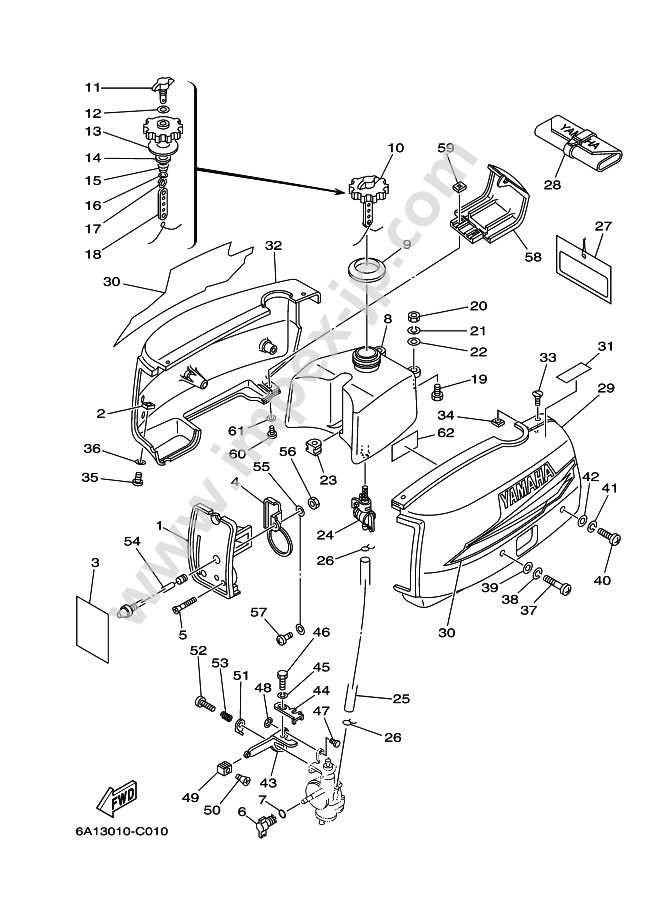

Maintaining Your Grooming Tools

Regular upkeep is essential for ensuring the longevity and optimal performance of your grooming device. Proper maintenance not only improves functionality but also reduces the likelihood of breakdowns and costly repairs. By dedicating time to care for each component, users can keep their tools running smoothly for years to come.

One of the most important aspects of maintenance is keeping the blades sharp and properly lubricated. This helps prevent uneven cuts and ensures smooth operation. It’s also essential to regularly clean the device, removing hair and debris that can accumulate and affect performance.

Another key area of focus is checking the alignment and tension of the cutting mechanism. Over time, parts may shift or loosen, leading to suboptimal results. Tightening screws and adjusting the tension can help maintain accuracy and prevent unnecessary wear.

Lastly, storing your device properly when not in use plays a crucial role in its preservation. Keeping it in a cool, dry place helps prevent moisture buildup, which can lead to rust or corrosion over time. Proper storage ensures that the tool remains in good condition and ready for use when needed.