Understanding the intricate details of your chainsaw’s internal system is essential for proper maintenance and repairs. This guide offers an in-depth look at the various elements that make up your tool, helping you identify, repair, or replace any faulty parts efficiently.

Accurate knowledge of the tool’s construction allows you to tackle common issues with confidence. Whether you are looking to improve performance or extend the lifespan of your equipment, recognizing key components is the first step toward successful upkeep.

By examining the assembly of your chainsaw, you’ll be able to diagnose potential problems and act quickly before they cause significant damage. With the right guidance, any repair process becomes more manageable, ensuring optimal functioning for every task at hand.

Understanding Chainsaw Components

Every chainsaw is made up of various interconnected elements that work together to ensure efficient operation. A solid understanding of these components is essential for proper maintenance and troubleshooting. From the engine to the cutting mechanism, each part plays a critical role in the overall functionality of the tool.

Key Components of a Chainsaw

The primary components include the power unit, bar, chain, and safety features. The engine is the heart of the machine, providing the necessary power to move the chain. The bar and chain assembly is responsible for cutting, while other elements like the carburetor and air filter ensure the engine runs smoothly. Additionally, safety components like the chain brake and throttle controls help prevent accidents during operation.

Importance of Proper Maintenance

Maintaining each component is crucial for the longevity of the tool. Regular inspections and replacements of worn-out parts, such as the chain or spark plug, will keep the chainsaw in peak condition. Understanding how each component interacts and ensuring they all function correctly helps avoid costly repairs and ensures the equipment performs reliably in various conditions.

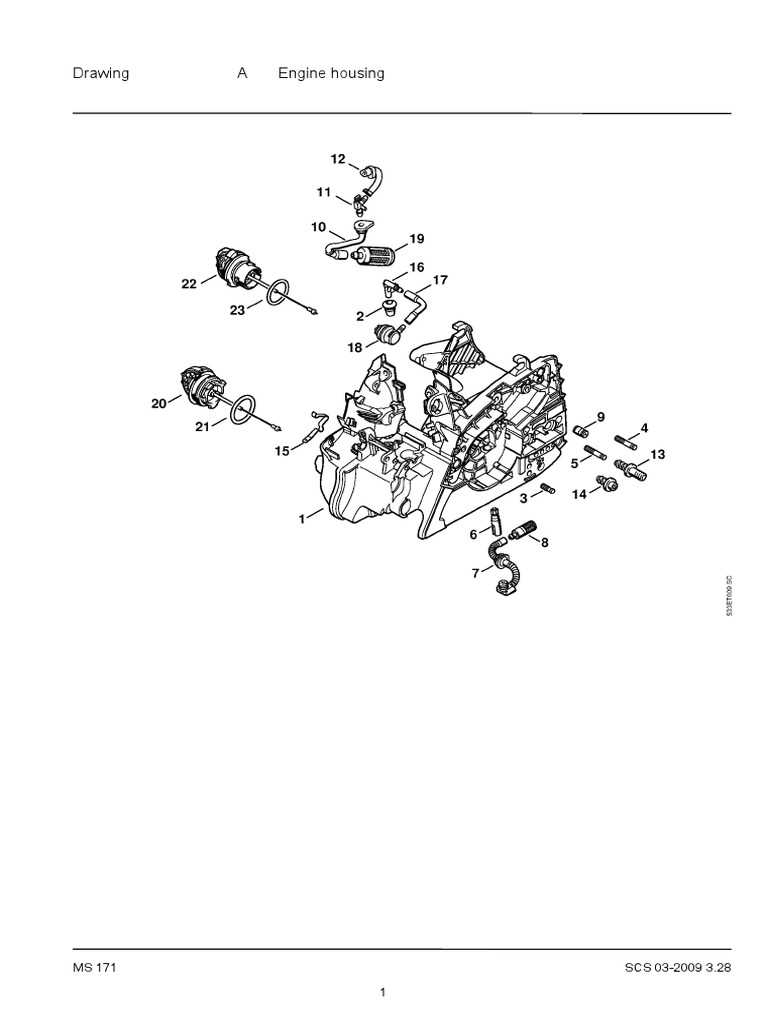

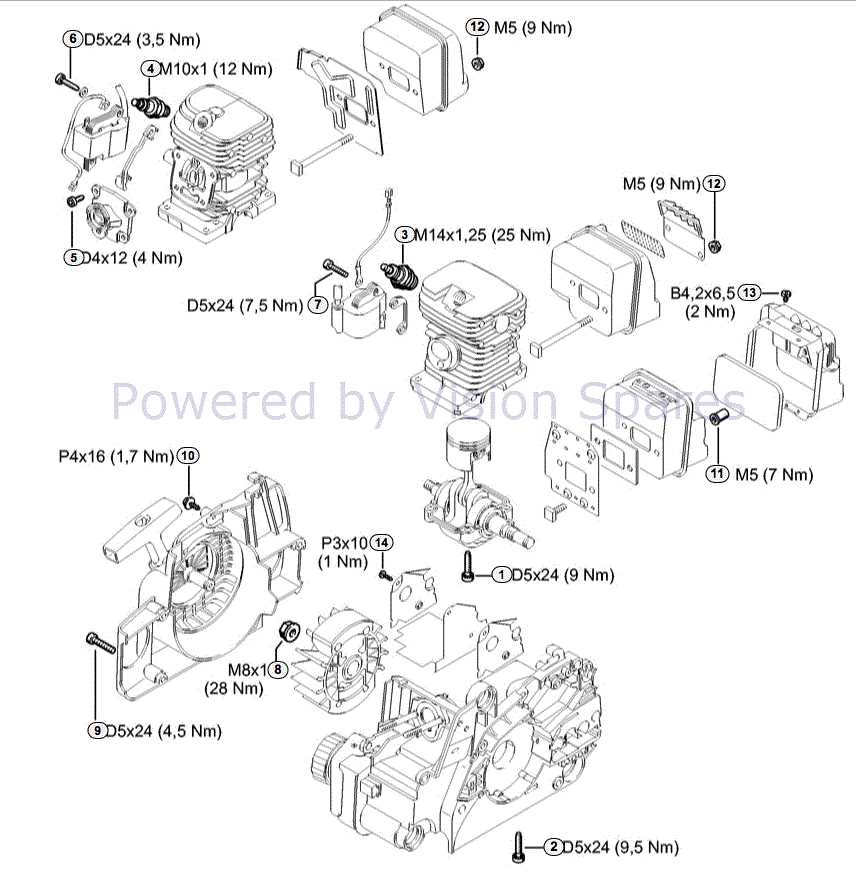

Identifying Key Parts in the Diagram

Recognizing the main components of a chainsaw and understanding their functions is crucial for effective repairs and maintenance. A detailed illustration of these elements can help you identify each part’s role and spot potential issues that may affect performance.

The engine assembly, guide bar, and cutting chain are among the most important elements to focus on. Understanding how each part is connected will help you troubleshoot common problems and make informed decisions when it’s time to replace a component. Additionally, being able to identify smaller parts like the spark plug, carburetor, and throttle can significantly improve your repair process.

By studying a clear representation of these components, you can ensure that every part is in its proper place, minimizing errors and maximizing efficiency. This understanding will not only save time but also prevent unnecessary wear and tear on your equipment.

How to Replace Chainsaw Components

Replacing worn-out or damaged parts in a chainsaw is essential for maintaining its efficiency and safety. Knowing the correct procedure for each component ensures that the tool operates at its best, extending its lifespan and preventing costly repairs.

Step-by-Step Replacement Process

The first step is to power down the tool and disconnect any fuel sources. After ensuring safety, you can begin by removing the damaged component, carefully following the manufacturer’s guidelines for disassembly. Pay attention to the positioning of each part so that the new piece can be installed correctly.

Common Replacements and Tools

Common components that often need replacement include the cutting chain, spark plug, air filter, and fuel filter. Having the correct tools for disassembly and reassembly will help simplify the process and avoid damage to other parts.

| Component | Typical Issue | Replacement Frequency |

|---|---|---|

| Chain | Worn or damaged teeth | Every 1-2 years depending on usage |

| Spark Plug | Difficulty starting, misfires | Every 1 year |

| Air Filter | Reduced engine performance | Every 6 months |

Following the proper procedures and replacing components on time can help keep your chainsaw running smoothly and safely. Regular checks and maintenance will help prevent unexpected breakdowns during critical tasks.

Step-by-Step Guide for Replacements

Replacing components in your tool is a straightforward process when done correctly. By following the right steps and using the proper tools, you can ensure that each part is replaced efficiently, helping your chainsaw run like new.

Preparation and Safety

Before starting any replacement process, always ensure the chainsaw is turned off and that there is no fuel left in the tank. Place the tool on a stable surface, and gather all necessary tools and replacement components. Having everything ready will minimize downtime and make the process smoother.

Replacement Process

Start by carefully removing the old part, ensuring that you don’t damage any surrounding components. For larger pieces, such as the engine or bar assembly, use the appropriate wrenches and tools. Once the old component is removed, inspect the area for any damage or debris before installing the new part. Attach the replacement securely and double-check its position before reassembling the tool.

Finally, test the tool by running it briefly to ensure everything is functioning correctly. If there are any issues, recheck the installation and make adjustments if necessary. By following this guide, you can replace components with confidence, ensuring optimal performance and longevity for your chainsaw.

Common Issues and Fixes for Chainsaws

Even the best-maintained chainsaws can experience issues over time. Recognizing common problems early can prevent further damage and keep the tool running smoothly. Here are some of the most frequent issues and how to resolve them efficiently.

Hard Starting or Engine Stalling

One of the most common problems is difficulty starting or stalling during operation. This can be caused by a few issues:

- Clogged air filter: If the filter is dirty, it restricts airflow to the engine, causing it to stall. Cleaning or replacing the filter can fix this issue.

- Dirty spark plug: A worn or fouled spark plug can cause misfires. Replacing the spark plug with a new one can resolve this problem.

- Old fuel: Stale fuel can cause starting issues. Ensure you’re using fresh, properly mixed fuel.

Chain Not Moving or Moving Slowly

If the chain isn’t moving or is moving too slowly, several factors could be at play:

- Chain tension: If the chain is too loose, it may not engage correctly. Adjusting the tension should restore smooth movement.

- Worn chain: Over time, the chain can lose its sharpness, making cutting more difficult. Sharpening or replacing the chain can help improve performance.

- Faulty clutch: A malfunctioning clutch might cause the chain to move irregularly. Inspecting and replacing the clutch could be necessary.

Oil Leaks

Leaks from the oil reservoir are common and often happen due to:

- Cracked oil tank: Inspect the oil tank for any visible cracks or damages that could be allowing oil to escape. Replacing the tank may be necessary.

- Clogged oil lines: If oil isn’t reaching the chain, check the oil lines for blockages. Clearing them can restore the oil flow.

By regularly inspecting your chainsaw and addressing these common issues, you can ensure its longevity and performance. Taking the time to troubleshoot and fix minor problems early will prevent larger, more costly repairs in the future.