Maintaining your gardening equipment is essential for ensuring long-lasting performance and efficiency. Knowing the individual parts and how they function can help you keep everything running smoothly, preventing unnecessary wear and tear. For any garden tool, understanding the structure is crucial, especially when it comes to identifying and replacing faulty components.

With a clear overview of the various elements, you can easily troubleshoot and manage repairs without relying on expensive professional services. Identifying each segment of the machine allows for faster and more accurate replacements, saving both time and money in the long run.

In this guide, we will walk you through the most important sections of your garden tool, explaining their roles and offering tips for proper maintenance. Whether you’re a seasoned gardener or a newcomer, this information will prove invaluable in ensuring your equipment stays in top condition.

Understanding Key Garden Tool Components

Every gardening machine is made up of a variety of essential elements that work together to ensure efficient operation. Each of these components plays a specific role in the overall functionality, and understanding their purpose can help with better maintenance and troubleshooting. Whether you are preparing soil for planting or handling other tasks, knowing how each part contributes to the machine’s performance is crucial for optimal use.

The structure of these devices often includes vital segments such as the engine, drive system, and various attachments designed for specific functions. Recognizing how each part interacts with the others allows for smoother operation and quicker identification of issues when they arise.

In this section, we will break down the most important components of your equipment. From the power source to the working tools, we will explain how they function together to deliver consistent results in your garden. Understanding these basic elements ensures you can manage the care and longevity of your machine effectively.

Common Garden Tool Replacement Components

Over time, certain segments of your gardening equipment will experience wear due to regular use. Understanding which components are most likely to need replacement helps you stay ahead of maintenance issues. Regularly replacing these key elements will keep your machine running smoothly and extend its lifespan.

Frequently Replaced Elements

- Drive Belts: These components transfer power from the engine to the working tools, making them essential for proper operation. Worn-out belts can lead to reduced performance or even complete failure of movement.

- Blades and Cultivating Tools: The working attachments that break up the soil tend to lose sharpness or get damaged. Regular replacement ensures efficient digging and reduces strain on the engine.

- Fuel Filters: Over time, fuel filters can become clogged, leading to decreased engine efficiency. Replacing them ensures proper fuel flow and optimal performance.

- Air Filters: Air filters prevent dirt and debris from entering the engine. If clogged, they can cause overheating or decreased power, so replacing them is crucial for longevity.

When to Replace Components

It is important to replace these elements at the first sign of damage or reduced performance. If the machine begins to operate less efficiently, such as sluggish movement or stalling, it may be time to check these key components. Proactive replacement can prevent costly repairs and downtime, ensuring that your equipment remains in peak working condition.

How to Use the Parts Diagram Effectively

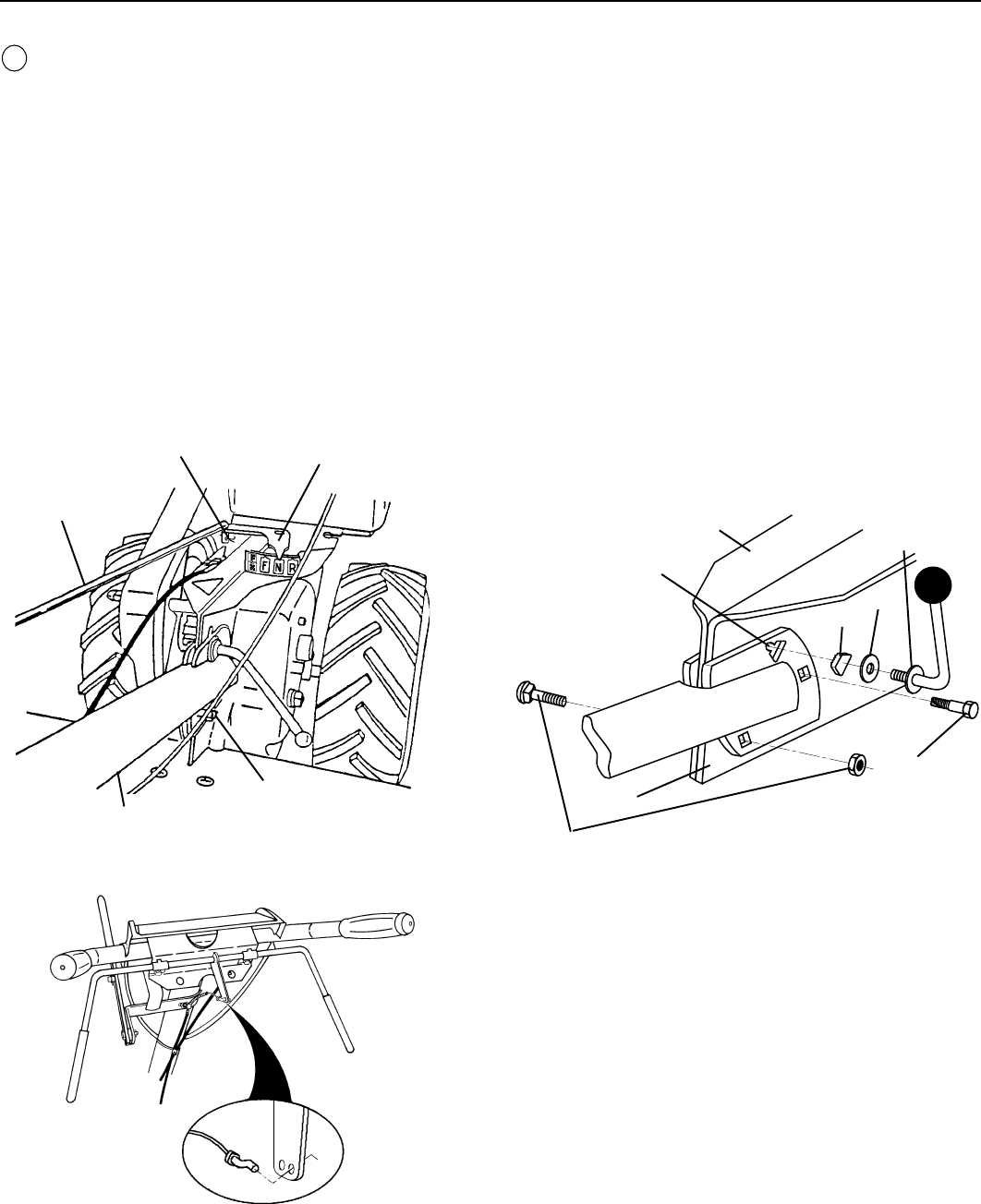

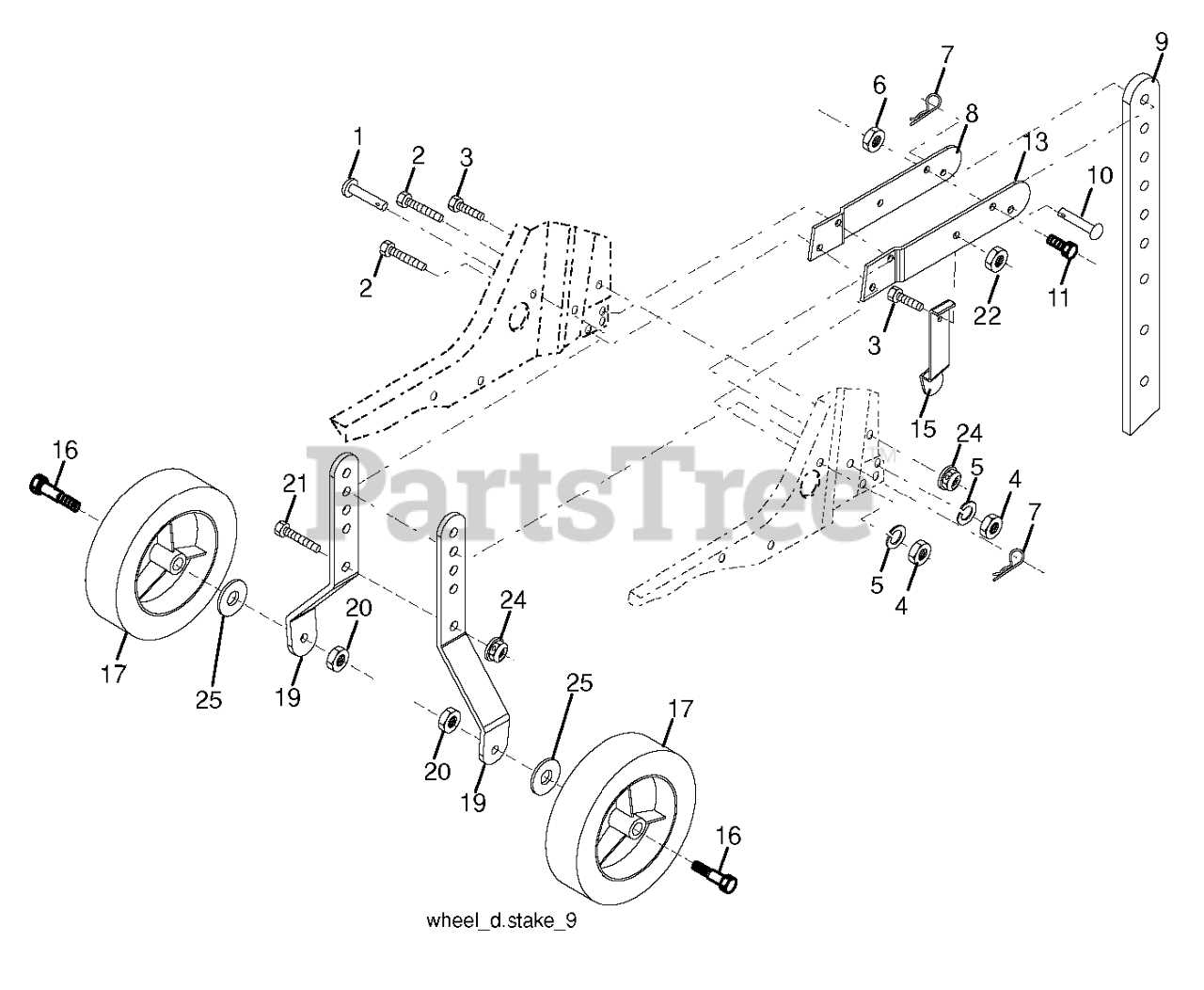

Using a visual reference guide is essential when working with complex equipment. A well-organized schematic can make it much easier to identify and locate specific elements within your machine. By understanding how to read and interpret these guides, you can streamline repairs, replacements, and maintenance tasks.

Start by familiarizing yourself with the layout of the diagram. Often, these guides are segmented into sections that correspond to different parts of the device, such as the engine, drive system, and attachments. Each part is typically labeled with a unique identifier or number, allowing you to quickly find the right replacement component.

Steps for Effective Use:

- Locate the section: Begin by finding the relevant section that corresponds to the part you need. This will save you time by narrowing down your search.

- Identify key components: Once you are in the right section, carefully examine each element. Pay attention to the relationships between the components and how they connect to one another.

- Cross-reference part numbers: Use the part numbers or labels provided in the diagram to ensure that you are ordering the correct replacement parts.

- Use for troubleshooting: If your machine is malfunctioning, a visual reference can help you identify which components might be causing the issue. Check for any worn or damaged areas on the diagram to compare with your equipment.

By following these steps, you can make the most out of the visual guide, ensuring that repairs are accurate and efficient. This approach also minimizes the risk of ordering the wrong components or missing critical maintenance tasks.