When working with complex machinery, understanding its internal structure is essential for maintenance and repair. Having a clear overview of each individual element allows technicians and operators to ensure the equipment functions efficiently. Whether you’re dealing with repairs, upgrades, or routine checks, knowing how the system is organized will save you both time and effort.

In this guide, we will explore how to recognize and locate key components within your machinery, providing detailed insight into their arrangement. This knowledge is invaluable for troubleshooting, replacing faulty elements, and performing necessary adjustments.

By mastering the internal layout, you can tackle any repair or maintenance task with confidence. A solid understanding of how each section contributes to the overall performance enables a smoother and faster process, ensuring that your equipment stays in optimal working condition.

Understanding TC Equipment Component Layout

Grasping the structure of your machinery is crucial for anyone involved in its upkeep or repair. A clear visual representation of the internal layout helps identify each individual section and its relationship to others, making it easier to diagnose issues or perform maintenance tasks. This clarity is essential for ensuring the smooth operation of the system and preventing unnecessary breakdowns.

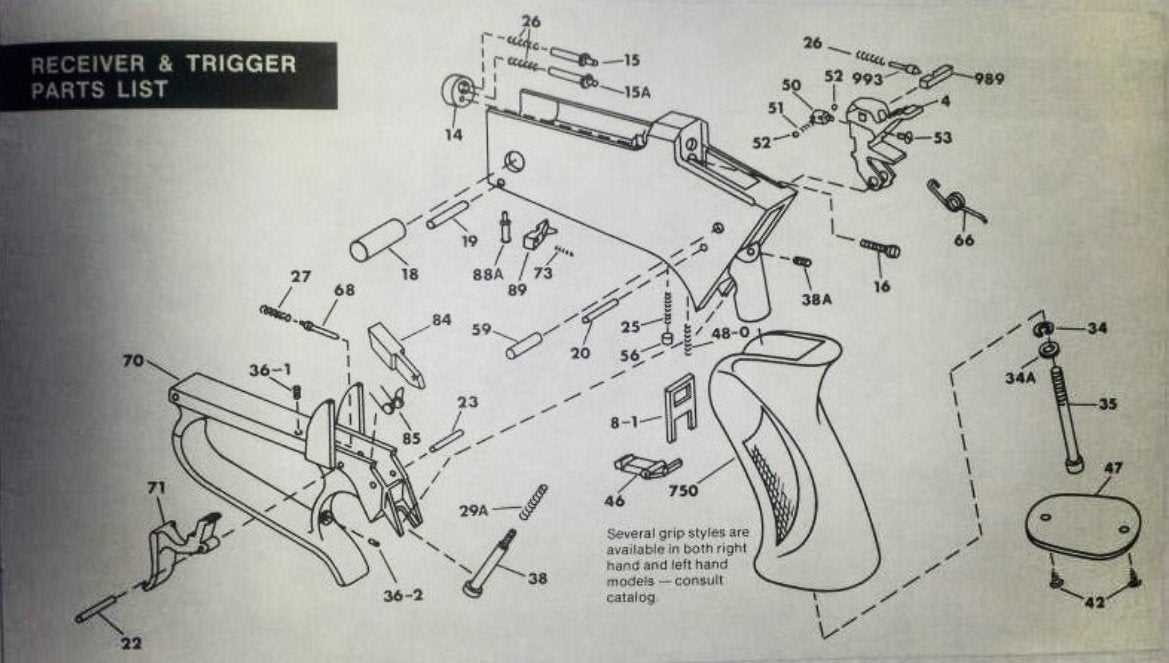

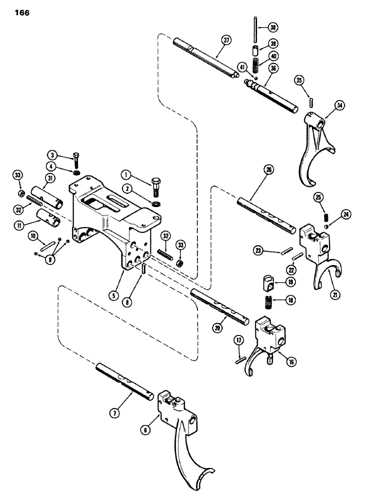

When you look at the organized schematic, it’s important to focus on how the different parts interact with one another. By understanding the positioning and connections, you’ll be able to quickly pinpoint areas that need attention. Such a layout often includes labels and numbers, which serve as guides to help technicians navigate through the machine efficiently.

This organized overview not only supports routine checks but also accelerates troubleshooting. With a solid understanding of the system’s framework, you are better prepared to make informed decisions regarding repairs or replacements, minimizing downtime and enhancing overall performance.

How to Identify TC Equipment Components

Recognizing individual elements within complex machinery is essential for effective troubleshooting and repair. Whether you’re handling maintenance or replacing a malfunctioning section, being able to pinpoint specific components quickly is crucial. A methodical approach to identifying each piece ensures that you can make informed decisions and perform accurate work.

Focus on Key Identifiers

The first step in identifying any component is understanding its role in the overall system. Each section typically has a unique shape, size, or connection type that distinguishes it from others. Labels or part numbers are often present on the components themselves, which can help you easily match them with references in the technical manual or online resources.

Utilize Visual References and Labels

Many systems provide visual aids that help you recognize parts in their correct positions. These can range from illustrations to detailed schematics, highlighting not only the location but also the purpose of each section. Pay attention to the color coding, markings, or numbers on the components to avoid confusion during your identification process.

Replacing Components Using TC Equipment Layout

When a malfunction occurs, replacing the faulty section promptly is essential to keep the system running smoothly. Having a clear visual guide to the internal setup helps you locate and replace the broken component efficiently. A structured layout of the machinery’s internal arrangement serves as a useful tool during the replacement process, ensuring minimal disruption and accurate repairs.

Step-by-Step Component Removal

Before beginning any replacement work, it’s important to carefully review the layout to understand the exact location of the malfunctioning part. Once identified, follow the outlined steps for removal to avoid damaging other components. Pay attention to the connections and fasteners, as they must be handled with care to prevent further issues when replacing the section.

Installing the New Section

After removing the defective part, the next step is installing the new one. Ensure that the replacement component matches the specifications outlined in the guide, and follow the installation steps closely. Verify the alignment and secure all connections before testing the system to confirm the new section is functioning properly.