When it comes to maintaining and repairing small boat motors, having a clear view of each individual component is essential. Proper knowledge of each element’s function helps ensure efficient performance and smooth operation. Knowing where every part fits into the overall system allows for precise repairs and replacement when necessary.

Accurate identification of the different motor components is crucial for performing maintenance tasks. Familiarizing yourself with each piece and its role in the engine’s function can save time and money by avoiding unnecessary repairs or misdiagnosis. Whether you’re fixing minor issues or conducting a full overhaul, understanding the layout of all key elements can greatly simplify the process.

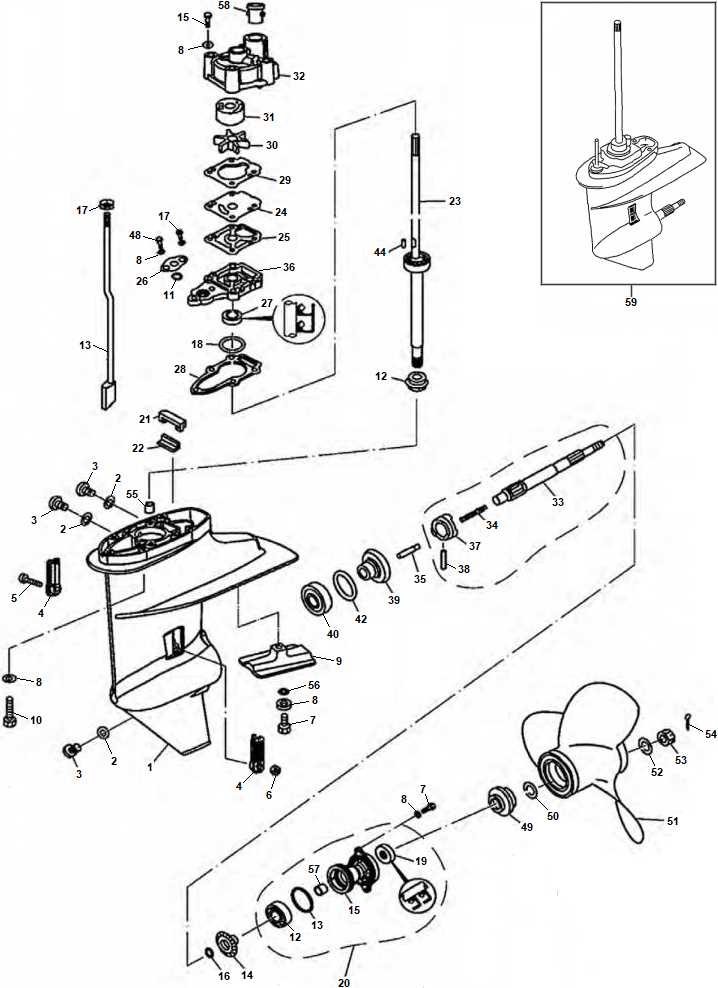

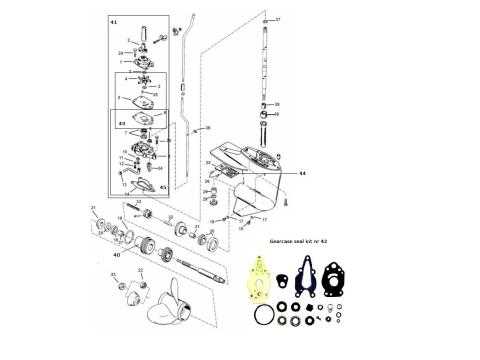

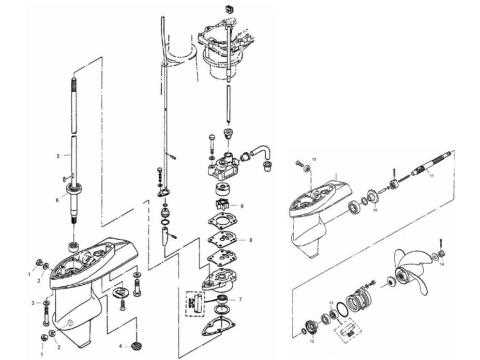

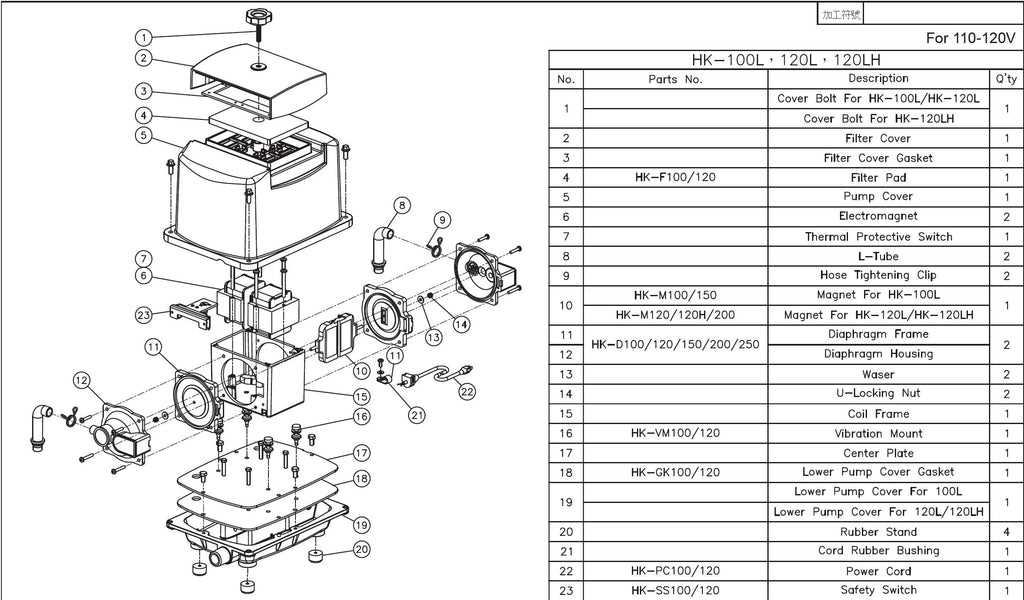

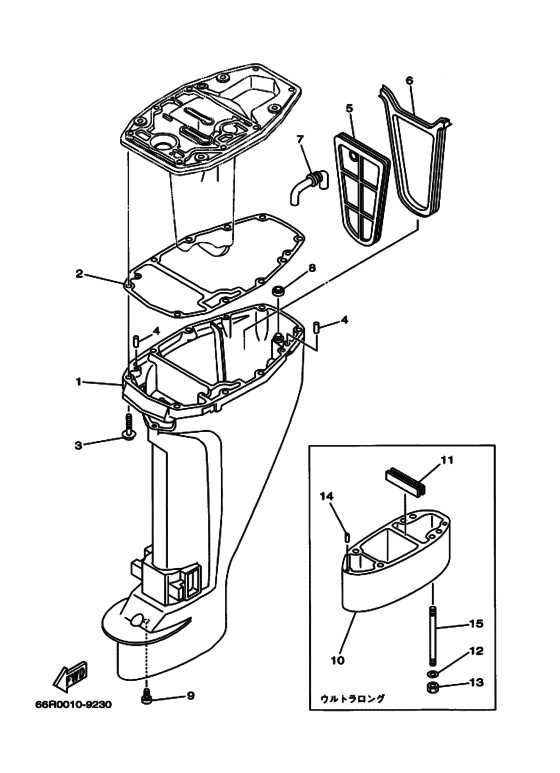

Using visual aids such as detailed schematics offers a step-by-step guide to the motor’s assembly, making it easier to locate specific parts and understand their interactions. This knowledge empowers owners and technicians alike to troubleshoot effectively and perform repairs with confidence.

Understanding Outboard Engine Components

When maintaining or repairing a small boat motor, it’s essential to grasp the overall structure and the function of each individual component. Each part plays a specific role in ensuring the engine runs smoothly and efficiently. A thorough understanding of these elements can lead to better troubleshooting and effective repairs, which will ultimately prolong the life of the motor.

Key Components and Their Functions

The engine consists of various systems that work together to generate power. These include the ignition system, fuel delivery system, cooling system, and exhaust system. Each of these components must be in good working order for the motor to operate at its full potential. Understanding how each system functions is crucial for identifying problems and performing repairs.

Locating and Identifying Engine Elements

Accurately locating each individual component within the motor helps simplify the repair process. Visual schematics can guide technicians in understanding where parts are positioned and how they interact. This knowledge minimizes the risk of errors during repairs and ensures that no part is overlooked.

Maintaining the engine requires attention to detail, as even a small issue with one component can affect the overall performance. Regular inspection and understanding the role of each system ensures that repairs are both timely and effective, keeping the motor in top condition.

How to Use the Parts Diagram Effectively

Having a visual guide of an engine’s components can significantly streamline the repair and maintenance process. These schematics provide clear, organized views of the engine, making it easier to locate and identify individual elements. By referring to such guides, you can ensure precise installation and efficient problem-solving.

Step-by-Step Approach

Start by familiarizing yourself with the layout of the engine. Each section of the visual guide corresponds to a specific part or group of components, typically organized by function or location within the engine. Begin with the major systems and work your way through to the finer details, ensuring that you understand how each element fits into the overall structure.

Identifying Issues and Replacements

Once you’ve grasped the basic layout, use the visual guide to pinpoint malfunctioning or worn-out components. The diagram helps you identify specific parts that need attention, allowing for easy comparison with new or replacement items. This approach minimizes the risk of confusion during repairs and helps you avoid unnecessary replacements.

By following these steps and referencing the guide regularly, you can improve repair efficiency and reduce the time spent troubleshooting. A clear understanding of where each part is located and how it functions together with others will lead to smoother maintenance procedures and longer-lasting engine performance.

Common Repairs for Outboard Engine

Regular maintenance and occasional repairs are vital to keep an outboard engine running smoothly. Over time, various components may experience wear and tear, leading to a decrease in performance. Identifying common issues and knowing how to address them can save time, reduce costs, and prevent further damage.

Fuel System Issues

One of the most common problems with outboard engines is related to the fuel system. Clogged fuel lines, dirty fuel filters, or a faulty fuel pump can prevent proper fuel delivery. Regular inspection and cleaning of these components are necessary to ensure the engine runs smoothly. If the engine struggles to start or runs unevenly, it’s often a sign that the fuel system needs attention.

Ignition System Problems

The ignition system is essential for starting the engine and maintaining consistent operation. A malfunctioning spark plug, faulty ignition coil, or wiring issue can cause starting problems or poor engine performance. Replacing spark plugs and checking the ignition coil and wiring regularly can help avoid these common issues.

Timely repairs to these systems can restore engine performance, improve fuel efficiency, and reduce the risk of breakdowns. By addressing common issues early, owners can avoid more complex repairs and extend the life of their engine.